mulletchuck said:Hey, ruckus. This thing sounds AWESOME as a single channel compressor too!!! had some fun with it tonight: http://twitpic.com/7p41rj <-- video with clean audio

nice playing!

mulletchuck said:Hey, ruckus. This thing sounds AWESOME as a single channel compressor too!!! had some fun with it tonight: http://twitpic.com/7p41rj <-- video with clean audio

Thanks for the reply, but I did not receive them like other mail outs he did. He had accidently forgotten to add me to the email out list so I am just trying to get hold of them now, since I can not move on this build without them.emrr said:he sent it twice, to your payment email address.

dandeurloo said:mulletchuck said:Hey, ruckus. This thing sounds AWESOME as a single channel compressor too!!! had some fun with it tonight: http://twitpic.com/7p41rj <-- video with clean audio

nice playing!

ruckus328 said:

Are you noticing anything funny going on with your build?SKJGProject said:i will wait some time until more people finish this with better test equipment as i'm not interested in taking it apart more than once...

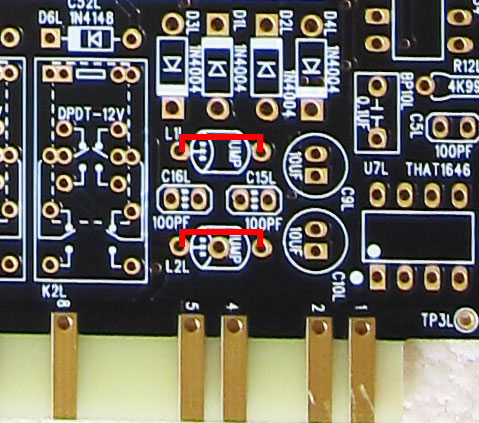

this fix is only for the variable release, right?

I was also confused as well, since he placed a note saying must jump on the other set item list but not on 3L and 3R list.SKJGProject said:is it necessary to jump jmp3l&r? ruckus only mentioned 1&2...

emrr said:if you wire the sweeper leg of a pot to an outer leg, it becomes a rheostat. Look it up.

So this means the rheostat connection isn't present on the circuit board, and I assume ruckus finds the bent leg to be the best solution. Since he modified all of his production units I would also assume the pots can take it just fine.

SKJGProject said:is it necessary to jump jmp3l&r? ruckus only mentioned 1&2...

therecordingart said:So is the release pot not working at all or did he wire the wiper to the wrong pin? My unit is at the studio so I can't confirm...funny we didn't notice an issue, but I'm not so sure the variance has been used at all.

If the wiiper isn't wired to anything on the PCB won't a jumper suffice without pulling the pot out?

SKJGProject said:is it necessary to jump jmp3l&r? ruckus only mentioned 1&2...

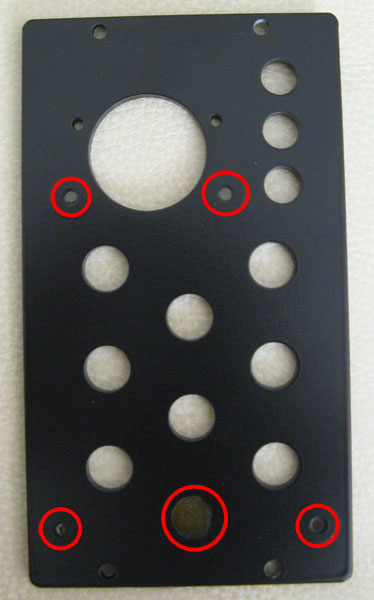

SKJGProject said:DONE!

there are 4 small nuts left and i have no idea where i forgot to use them ;D

the small tool for the knob-screw was not included, right?

i'm also a bit confused about the right orientation of the tl704? should i align the "cutout" of the chip-body with the one in the socket?edit: answer found here

afterwards i only need to build a 51x-rack to use this baby ;D

Enter your email address to join: