I have some preliminary test results of the Point to Point build vs. the PCB based mics and the results are so far completely inconclusive. I post now because there was some overlap with Category 5's findings on the CT12 capsule. I will likely send a capsule back to Tim to have a closer look.

So, I did 2 rounds of testing on the PTP build. The results are completely inconclusive at best, but we have some results folks can look at which is probably better than no results. A quick summary is in our listening environment, this particular point to point microphone sounds better than the particular PCB microphone, but the reasons for the difference point to component variation as opposed to differences invoked by ptp vs. pcb construction of the circuit.

1st test. . . the point to point microphone to our ears sounded more open than the pcb build. These are close mic recordings of acoustic guitar. Because shifting the mic position even 3/4" influences the tone dramatically, we recorded separate takes with each microphone.

Point to Point clip

https://drive.google.com/file/d/0B5bvhqkG9T7fV0pucDN2dlgzQk0/edit?usp=sharing

PCB clip

https://drive.google.com/file/d/0B5bvhqkG9T7fQmxmaXowQmtsd1E/edit?usp=sharing

After the results from the first test, my chosen method of result confirmation in the 2nd test session was to completely teflon isolate the hiZ section of the PCB build . . . basically modify and isolate the "lesser" microphone in steps until it rivals our "good" microphone. . .this is done with the same methodology as the point to point build, so the isolation characteristics should be identical. The results to our ears were indistinguishable between the PCB configuration and the same microphone modified with teflon isolated HiZ. Note, these are the exact same components re-used.

PCB with teflon isolated HiZ section

https://drive.google.com/file/d/0B5bvhqkG9T7fUTBmeUJZSTlvV2s/edit?usp=sharing

Mathematically, even though in theory, it is far outside of the range that would effect circuit performance, it can be argued that the HiZ section could effect tone, so I isolated that section for testing. By the same token, by the numbers, there can be no tangible gains minutely possible by isolating the low Z sections of the PCB, so while I can go further and teflon isolate the entire PCB based microphone, it would likely be a waste of time. So, my leaning based on no perceptible sonic gains from isolating the most likely culprits from stray capacitance and current leaks was to examine the core components (Tube, transformer, capsule). In our first test day, we had 2 tubes and the tubes did exhibit some tonal differences, and these differences did follow the tube between the 2 test microphones, but the differences were small enough for us to consider them "flavor" differences.

This testing was done on a pre-production prototype of the PCB board microphone, so the FC and RC screen prints were reversed on the PCB, which led me to wire up the front and rear capsules in reverse when I completed the modifications. Back to what Category5 observed, the "rear" side of this particular CT12 capsule sounded much more open and nuanced than the front side when listening in cardioid mode on the bench after making the modifications. For our testing purposes, to maintain consistency, I wired the microphone using the same capsule side as the 1st test when preparing the microphone for the 2nd round of testing. . . but, in studio after confirming no sonic improvements from isolating the HiZ, I remembered that the back side of the capsule was "better" when I tested on the bench, so I took out a soldering iron in studio and switched our PCB mic to the rear side of the capsule.

PCB microphone with isolated HiZ back side of capsule

https://drive.google.com/file/d/0B5bvhqkG9T7fZFVOS1BueDNSQk0/edit?usp=sharing

The effects of that change were noticeable/tangible. The PCB microphone "closed the gap" significantly in openness and articulation compared to our baseline point to point build.

So, my take-away from this very imperfect test.

1. This particular point to point microphone is the "better" microphone of the 2 tested.

2. Teflon isolating the HiZ portion of the circuit yields no perceptible sonic gains.

3. Switching to the back side of the capsule (essentially changing capsules) DID result in sonic gains.

Further testing is necessary to make a more solid determination, but my leaning at this point is the PCB setup is sound. If isolating the HiZ section of the microphone produced tangible improvements, I would absolutely change the build documentation to reflect this as the "prescribed" build methodology. We are committed to providing a kit that delivers uncompromising sonics!

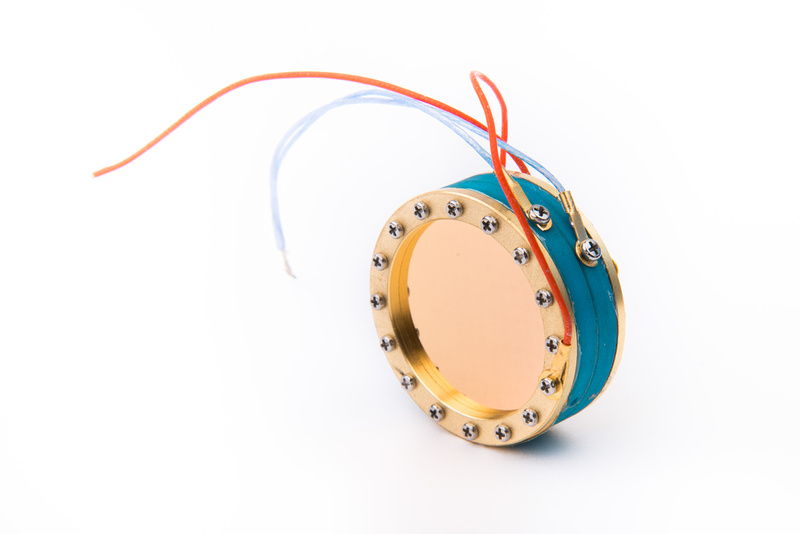

More information can be derived from switching the capsules and transformers between the PTP microphone and the PCB microphone to see if that reverses the standing of the 2 builds. Due to the now scarce nature of the CT12 capsules, the microscopically small mounting screws, and limited light and tools in the studio, I opt to make these preparations on my workbench for further testing instead of attempting the swap in-studio.

Note: the standard C12 PCB set can be easily modded to make partial or fully teflon isolated point to point builds by enlarging the turret holes with a 9/64 inch bit and buying a handful of Keystone 11308 press-fit teflon turrets. The same 9/64 inch bit can be used to enlarge the grid connection point on the tube sub-PCB to float that connection as well.