[silent:arts]

Well-known member

no ??? ;D

not yet

not yet

- well the Prototype PCBs should arrive next weekdandeurloo said:any sort of timeline? Sorry to bug.

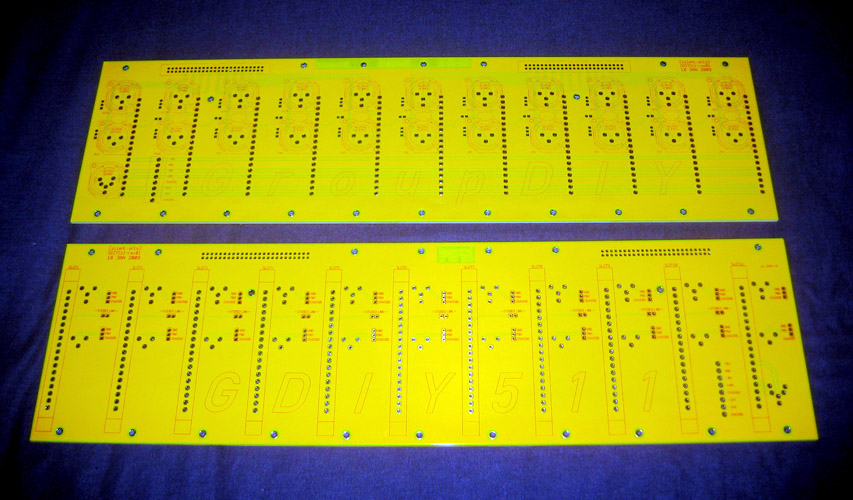

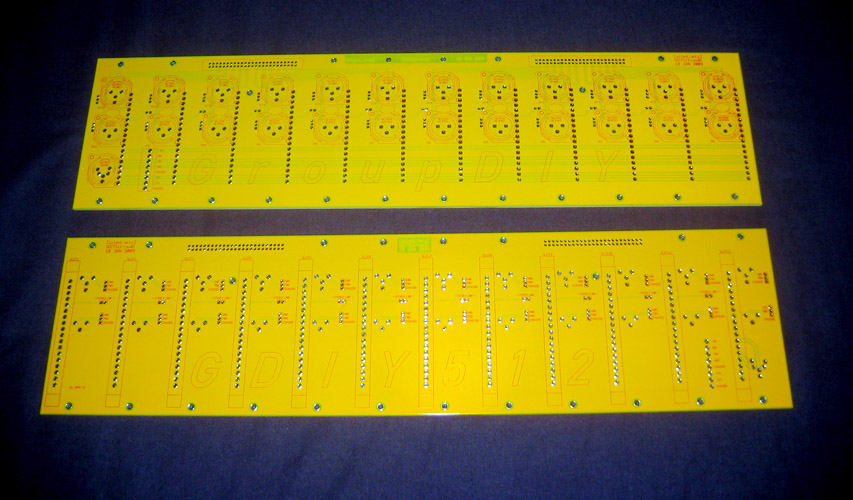

[silent:arts] said:GDIY511:

;D ;D ;Dbernbrue said:... Hope to see you in a yellow T-shirt soon ...

valid points, thanks for the suggestions.jdbakker said:On the final version you may want to consider mounting holes for the EDAC connectors. Without those, module insertion/extraction stresses are transferred directly to the solder joints, and that's a maintenance nightmare waiting to happen, especially for equipment used on tour. The same goes for the Neutriks: directly soldering them to the board is not a good plan, even with an extra-thick PCB.

Lining up the board mounting holes with the Neutriks and not the EDACs is somewhat questionable, depending on the stiffness of the case.

I could include T-shirts as a further option ;DHarpo said:... Lemonblack is the upcoming colour for T-shirts. ;D

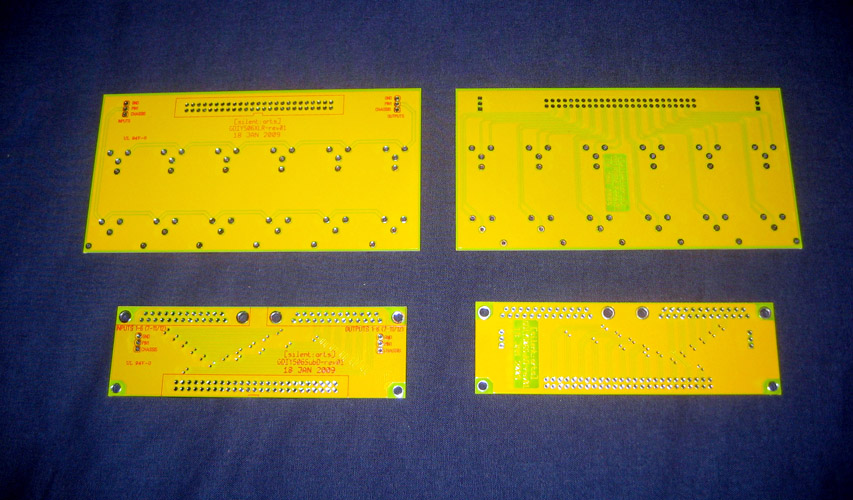

[silent:arts] said:EDACs:

- haven't seen the EDACs screwed down on any 500 Rack before (API (in real), Purple Audio, etc (photos only))

[silent:arts] said:XLRs:

- they are only soldered directly to the backplane if you want to do an API500 only version without the extra features

- if you use the "remote I/O connectors" (XLR or SubD) they are soldered on extra PCBs

[silent:arts] said:for sure there is a way to build the best, robust and tour safe version.

the intention of this thread was to do a cost effective DIY version.

we included loads of features.

no way to include all