The last time I made speakers on the forum was some Auratones, way back in 2011.

https://groupdiy.com/index.php?topic=43086.0

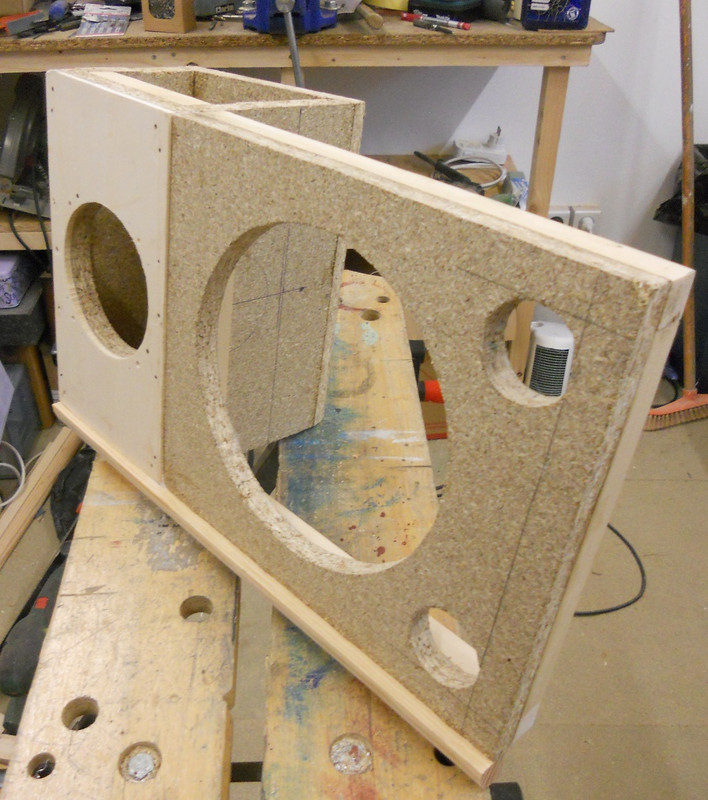

This will be way more challenging, but that's how we learn. These will be passive units with first order series crossovers.

I have wound some air coil inductors for nominal crossover frequencies of 500Hz and 5000Hz

I have some top end bass drivers from an old project that I will re-use, they are 8" Monacor SPH-200KE units.

https://www.monacor.com/products/components/speaker-technology/hi-fi-speakers/sph-200ke/

They only need a relatively small cabinet volume so they are ideal for monitors. they will be around 20Litres.

The mid ranges are Monacor MSH-115's

https://www.monacor.com/products/components/speaker-technology/hi-fi-midrange-speakers/msh-115/

They have one of the flattest frequency responses I've seen and I have them in my hi-fi speakers too.

As discussed in the drawing board thread, the main problem is minimising diffraction effects in the mid- treble region.

https://groupdiy.com/index.php?topic=68928.0

If your monitors have excessive dips and peaks you can't be expected to hear the detail or EQ effectively.

If you wonder why I'm bothering with passive monitors, take a look at the electronic junk inside this active monitor.

Do I really want my sound going through all this crap?

https://www.youtube.com/watch?v=dftkoD7LG0A

DaveP

https://groupdiy.com/index.php?topic=43086.0

This will be way more challenging, but that's how we learn. These will be passive units with first order series crossovers.

I have wound some air coil inductors for nominal crossover frequencies of 500Hz and 5000Hz

I have some top end bass drivers from an old project that I will re-use, they are 8" Monacor SPH-200KE units.

https://www.monacor.com/products/components/speaker-technology/hi-fi-speakers/sph-200ke/

They only need a relatively small cabinet volume so they are ideal for monitors. they will be around 20Litres.

The mid ranges are Monacor MSH-115's

https://www.monacor.com/products/components/speaker-technology/hi-fi-midrange-speakers/msh-115/

They have one of the flattest frequency responses I've seen and I have them in my hi-fi speakers too.

As discussed in the drawing board thread, the main problem is minimising diffraction effects in the mid- treble region.

https://groupdiy.com/index.php?topic=68928.0

If your monitors have excessive dips and peaks you can't be expected to hear the detail or EQ effectively.

If you wonder why I'm bothering with passive monitors, take a look at the electronic junk inside this active monitor.

Do I really want my sound going through all this crap?

https://www.youtube.com/watch?v=dftkoD7LG0A

DaveP

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)