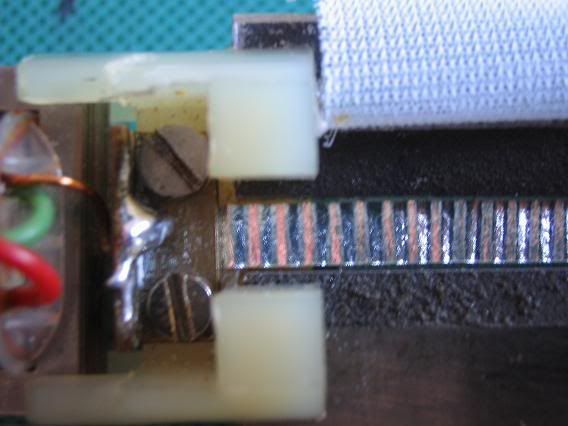

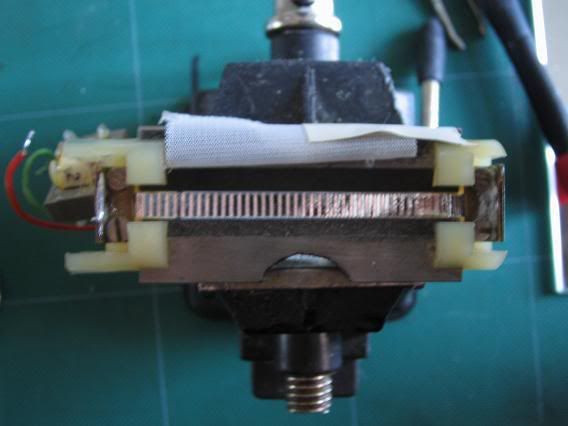

I've just finished replacing the ribbon on the top section of a BM-5, the old one had sagged to such and extent that is was dragging on one of the poles. My hamfisted attempted to tighten it destroyed it, mind you it was never gonna be possible to adjust it, as the ribbon had corroded/stuck itself onto the mounting clamp.

Phew, it was a fiddly job. I used some 'silver' leaf stuff that I found in the drawer - I'm guessing it's what people are suggesting is .6 micron (?). I couldn't find any suitable gears so corrugated the ribbon around a hosepipe 'thingy'. Took several attempts but eventually plugged the thing in, it worked and more amazingly sounded pretty good. BUT It's about 4 or 5 dB down on the other half of the mic.

SO:

I assume I've lost level because I made the ribbon a littler thinner (widthwide), so the ribbon to poles gap is larger than it was before ? FWIW the old ribbons were Duralum - and have a slightly different shape to other ribbons I've seen. They were corrugated for about 1cm at the ends but the center section was slightly curved.

OR:

is the new ribbon foil too thin ? too high a resistance (it's about 5cm long) ?

I also think that the foil I used is too flimsy to hold it's corrugations - so the bends aren't nice and crisp like pictures of other ribbons I've seen. Would randomly pounding the foil with a hammer halp introduce some springyness ? It would have been great to have one of those RCA corrugating machines in the photo that rodabod posted. With better corrugation there would be more mass of foil inside the poles - how would that affect the output ?

any advice gratefully received.

Phew, it was a fiddly job. I used some 'silver' leaf stuff that I found in the drawer - I'm guessing it's what people are suggesting is .6 micron (?). I couldn't find any suitable gears so corrugated the ribbon around a hosepipe 'thingy'. Took several attempts but eventually plugged the thing in, it worked and more amazingly sounded pretty good. BUT It's about 4 or 5 dB down on the other half of the mic.

SO:

I assume I've lost level because I made the ribbon a littler thinner (widthwide), so the ribbon to poles gap is larger than it was before ? FWIW the old ribbons were Duralum - and have a slightly different shape to other ribbons I've seen. They were corrugated for about 1cm at the ends but the center section was slightly curved.

OR:

is the new ribbon foil too thin ? too high a resistance (it's about 5cm long) ?

I also think that the foil I used is too flimsy to hold it's corrugations - so the bends aren't nice and crisp like pictures of other ribbons I've seen. Would randomly pounding the foil with a hammer halp introduce some springyness ? It would have been great to have one of those RCA corrugating machines in the photo that rodabod posted. With better corrugation there would be more mass of foil inside the poles - how would that affect the output ?

any advice gratefully received.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)