The Sugar Lion

Active member

- Joined

- Oct 7, 2016

- Messages

- 32

Hey Ricardo

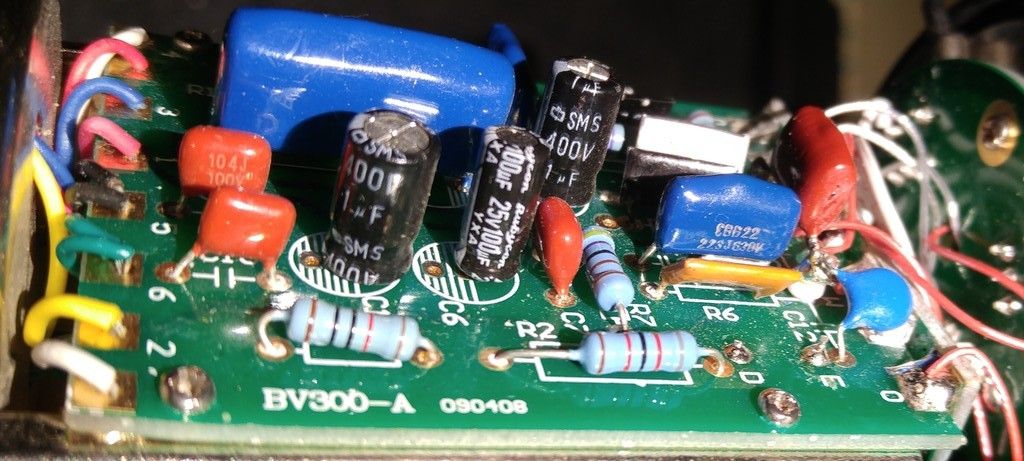

I realize that it is a tube mic and some pleasing level of distortion is a good thing but I was just wondering if things could be improved slightly. I appreciate that this might not be the case. If this is true then perhaps at this point I have a different question all together and that would be .... Do you have any suggestions for possible upgrades I could make to this mike to improve it at all? I am thinking the simplest and most obvious change to improve clarity would be to upgrade the capsule. I just wonder if that is a bit of a waste of time if the foundation for the capsule is not there. I would be interested in what your thoughts where on this.

I appreciate what your saying about the supa dupa tubes. I had a better tube sitting around doing nothing so I threw it in there but I am guessing it is not making much if any meaningful difference.

The microphone parts kits look great and I fully intend on building one when the time is right.

What you had said about heating the tube I took completely the wrong way. I thought you where suggesting that I just take the tube completely out of the influence of the audio path and just "heat" it up so it looks pretty in the mic type of thing. Sorry totally misunderstood what you where saying and it put a negative spin on the post, hence some of the reason for my grumpy mood. I am sorry about that.

All the best

I realize that it is a tube mic and some pleasing level of distortion is a good thing but I was just wondering if things could be improved slightly. I appreciate that this might not be the case. If this is true then perhaps at this point I have a different question all together and that would be .... Do you have any suggestions for possible upgrades I could make to this mike to improve it at all? I am thinking the simplest and most obvious change to improve clarity would be to upgrade the capsule. I just wonder if that is a bit of a waste of time if the foundation for the capsule is not there. I would be interested in what your thoughts where on this.

I appreciate what your saying about the supa dupa tubes. I had a better tube sitting around doing nothing so I threw it in there but I am guessing it is not making much if any meaningful difference.

The microphone parts kits look great and I fully intend on building one when the time is right.

What you had said about heating the tube I took completely the wrong way. I thought you where suggesting that I just take the tube completely out of the influence of the audio path and just "heat" it up so it looks pretty in the mic type of thing. Sorry totally misunderstood what you where saying and it put a negative spin on the post, hence some of the reason for my grumpy mood. I am sorry about that.

All the best

ricardo said:No I don't think its junk. But if you want to "improve the output, overall clarity and noise levels ", the Microphone Parts kit will be cheaper, easier and give better results than eg buying supa dupa tubes .. or any other solution that keeps the tube(s).

If your comments about the sound were different, I might have recommended other stuff. But if we assume you are not deaf and are reporting accurately, my recommendations still stand.

I've advised on tube mike design for other forum members.

And I'm serious about using the tube filament to heat the mike. As I said, I designed this into what was at the time, the most expensive mike you could buy.

![TC1-schematic[1].png](https://cdn.imagearchive.com/groupdiy/data/attachments/19/19115-d8ab349732acfc7834fa797997249ef8.jpg)

![ECC83_82_Socket[1].gif](https://cdn.imagearchive.com/groupdiy/data/attachments/19/19121-afa9811784343c2cc49239a95c66a3d1.jpg)