I had another project with a MBB switch, so I opened up one of the switches, and the way they make them BBM is they have little "risers" between the contacts.

This is the BBM

This is the MBB version, no bumps, the contact rides down and makes before breaking.

If I only had a little chisel... To remove the bumps. So I hammered on an old worn out soldering iron point, and clipped the end.

At about 600 degrees F the plastic is very soft, but not liquid. Cooler may be better. God only knows what fumes I breathed when doing this, I was careful to leave no little pieces in there. And I didn't know what type of grease was in there (speak up if you do) so I use a little de-oxit.

It doesn't look pretty, and it took 20 minutes for one switch (after making the tool, which needs to be sharp and narrow, if I had a narrow chisel it would be better, they would pop off clean and pretty).

The switch works like a MBB now, and when changing the gain the changes are better. Still not super clean. Stop 4 is always a pop because of the electrical architecture ( I wonder if a high value drain or leak resistor somewhere would fix that) it pops the first time you turn past it. Anyway after that test I am sure that MBB would be better, and I ordered the MBB parts from mouser, I can always change the switch shafts and use the ones I have.

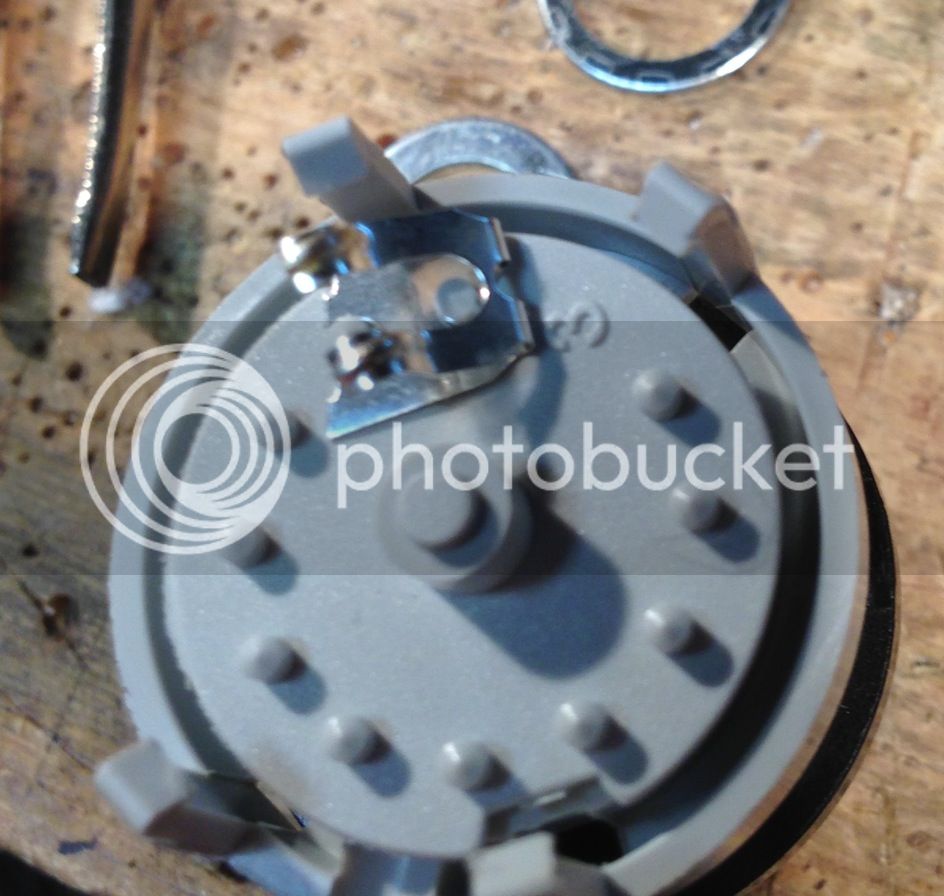

If you do pop one of these apart, keep the shaft pulled tight into the front section or you might lose the little ball and spring, which is small, and can be hard to get back in. You will almost always dislodge the contact spring which is loose. There is no problem with that but you will wonder where to put it back so I thought this picture would help, you put it back right next to the number like this.