thecr4ne

Well-known member

I recently got a pair of Altec 150A Coke Bottles with 21B capsules, but no power supplies. Given the prices and rarity, and what I have on hand, I think I'm better off just building my own PSU. I consider myself a novice at best, so I'd appreciate any feedback on my design logic.

Fair warning. Lots of images here interspersed with text.

I'm considering building a single PSU for both mics, like this one (currently for sale on reverb for more than I can afford) credited as build by Greg Norman of Electrical Audio.

I've never really designed or re-designed a PSU before, so I'm planning on mostly sticking to the original schematic for the P518A/P519A, but with separate audio sections for each mic.

I can't find any useful info on the original TP-608-A power transformer. I know I need something that can put out 300V once rectified/filtered, plus filament with enough current to power 2 6au6 tubes.

I've got a Hammond 269EX on hand that I think will do the job, but I'd appreciate if anyone with more knowledge can confirm.

On the audio side of things, I was actually able to find some info on the original TBB-103 Output transformers.

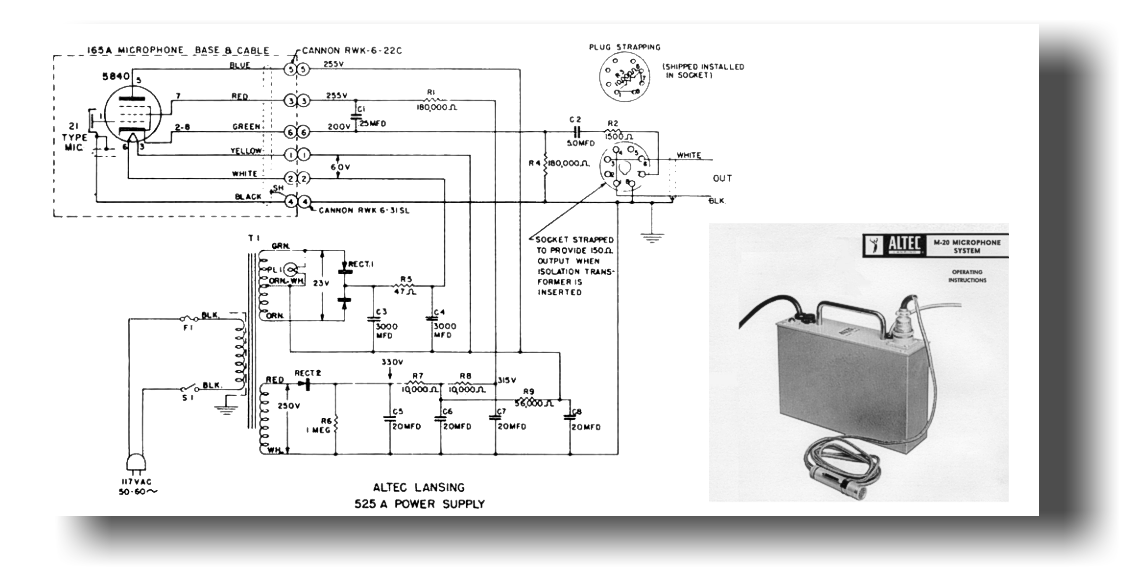

They're not easy to come by though, and I'm trying to keep costs down. That said I have a few (also expensive and hard to come by) 4665 transformers from my Altec 525A Lipstick mic PSUs.

Specs seem functionally comparable. The 4665's Octal socket form factor makes it favorable in that I can use it for different applications with no soldering required.

Beyond that I can get my hands on the rest. I really just need to make sure I don't do anything stupid that could destroy the mics or output transformers. In the coming days I may try my hand at adding onto the schematic what I think makes sense, but I'm guessing I won't get it right on the first shot so any help is appreciated.

*NOTE*

I originally posted about whether the coke bottle would work with the lipstick PSU. Instead of creating a new thread, I just hijacked my own.

Original Post Below:

I've got some healthy recapped Altec 525A's with 4665 OTs, and recently got a Coke Bottle without it's power supply. I'm looking at the schematics and trying to see if I can use the Coke Bottle with the 525A.

Plate Voltage is 6% higher on the 518A coke bottle PSU (270V vs 255V)

Grid Voltage is 4% higher (265V vs 255V)

Cathode and heater voltages are the same.

The difference I do see is how the control and suppression grids, and backplates are wired.

Can anyone explain what's going on there and if there's any other considerations I should be aware of?

(Obviously a cable would need to be made, which is no issue)

Fair warning. Lots of images here interspersed with text.

I'm considering building a single PSU for both mics, like this one (currently for sale on reverb for more than I can afford) credited as build by Greg Norman of Electrical Audio.

I've never really designed or re-designed a PSU before, so I'm planning on mostly sticking to the original schematic for the P518A/P519A, but with separate audio sections for each mic.

I can't find any useful info on the original TP-608-A power transformer. I know I need something that can put out 300V once rectified/filtered, plus filament with enough current to power 2 6au6 tubes.

I've got a Hammond 269EX on hand that I think will do the job, but I'd appreciate if anyone with more knowledge can confirm.

On the audio side of things, I was actually able to find some info on the original TBB-103 Output transformers.

They're not easy to come by though, and I'm trying to keep costs down. That said I have a few (also expensive and hard to come by) 4665 transformers from my Altec 525A Lipstick mic PSUs.

Specs seem functionally comparable. The 4665's Octal socket form factor makes it favorable in that I can use it for different applications with no soldering required.

Beyond that I can get my hands on the rest. I really just need to make sure I don't do anything stupid that could destroy the mics or output transformers. In the coming days I may try my hand at adding onto the schematic what I think makes sense, but I'm guessing I won't get it right on the first shot so any help is appreciated.

*NOTE*

I originally posted about whether the coke bottle would work with the lipstick PSU. Instead of creating a new thread, I just hijacked my own.

Original Post Below:

I've got some healthy recapped Altec 525A's with 4665 OTs, and recently got a Coke Bottle without it's power supply. I'm looking at the schematics and trying to see if I can use the Coke Bottle with the 525A.

Plate Voltage is 6% higher on the 518A coke bottle PSU (270V vs 255V)

Grid Voltage is 4% higher (265V vs 255V)

Cathode and heater voltages are the same.

The difference I do see is how the control and suppression grids, and backplates are wired.

Can anyone explain what's going on there and if there's any other considerations I should be aware of?

(Obviously a cable would need to be made, which is no issue)

Attachments

Last edited: