I just did a simple test and found that any inductive effect is negligible.

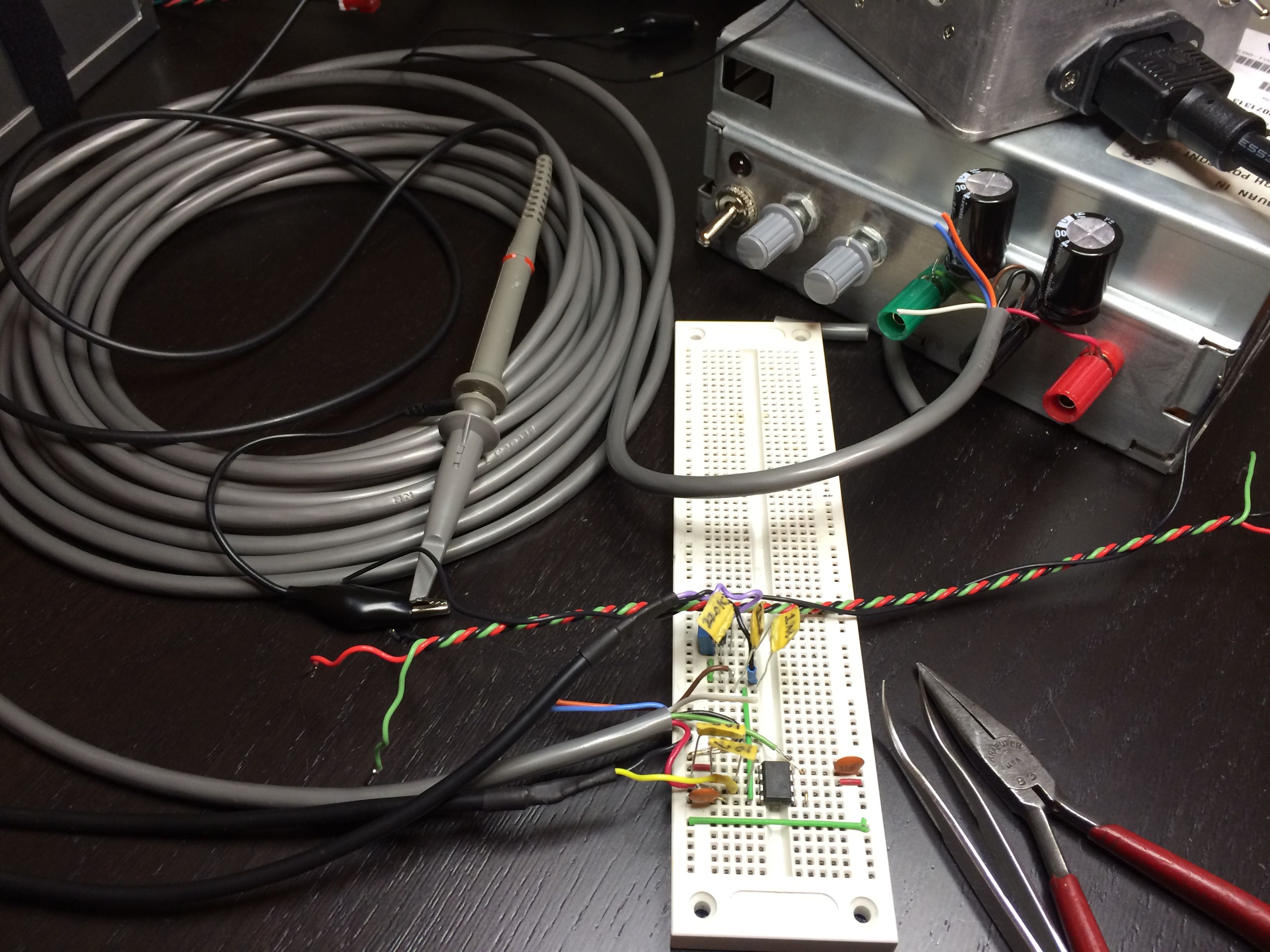

Specifically, I created a simple non-inverting op amp TL082 stage with + grounded and +40 dB of gain. Next to that (but separate), I created a simple Mosfet circuit that would just sink current based on my audio analyzer [1] sine stimulus. I adjusted the stimulus level so that the Mosfet would turn on to the point where it's drain voltage would drop ~8V of a 15V supply across a 220 ohm resistor. So that should be ~36 mA peak. So the analyzer output drives the Mosfet while the input is listening to the op amp and the idea is that if there's any crosstalk, I'll see a peak.

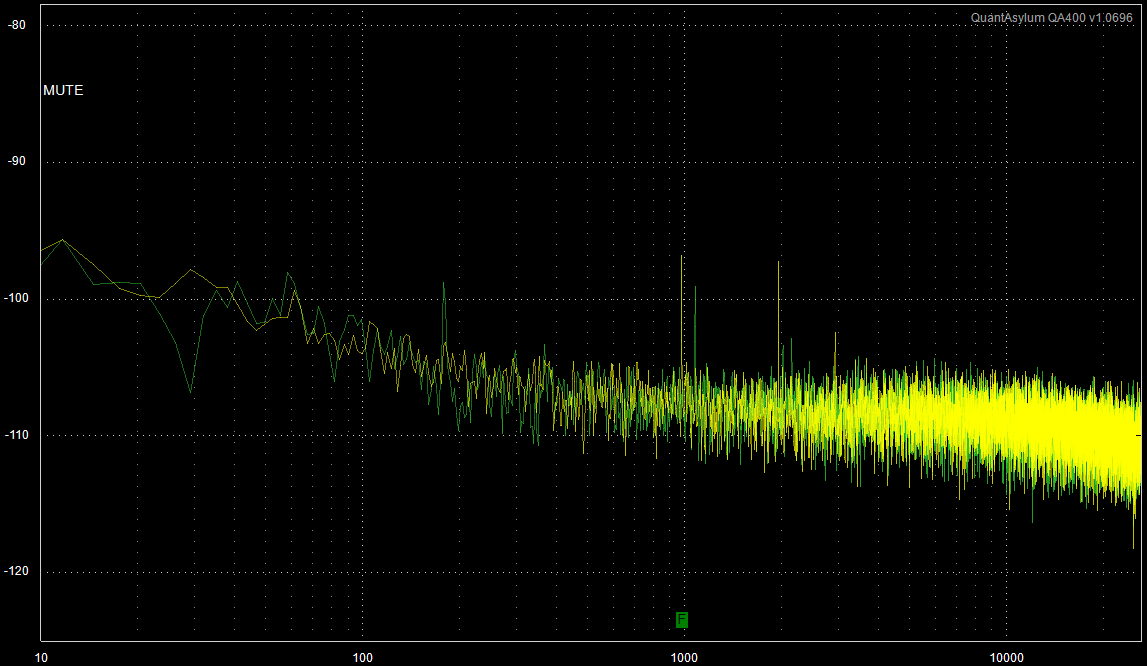

So at first I used relatively short power leads, got a small peak (green trace in the graph below at 1.08kHz) and saved that. I noted at this point that thin breadboard jumper wires were very bad so I used high quality 20 AWG wire with header pins soldered on the end.

Then I inserted 22 ft (6.7 m) of Belden 7 conductor 22 AWG unshielded cable to deliver power to the circuits. At first I connected the Mosfet ground to the op amp ground locally and got a peak +25 dB greater than the "small peak". I noted that it made a significant difference where the ground was connected but the best case was +25 dB.

Finally, I used a separate conductor for the Mosfet ground. So the Mosfet ground and op amp ground used separate conductors that run back over the 22 ft of cable directly to the filter caps on the power supply. This is the yellow trace at 990 Hz:

As you can see, the difference between short power wires (green trace at 1.08 kHz) and 20+ ft of 22 AWG conductor with separate grounds (yellow trace at 990 Hz) is only about +2 dB (albeit with a notable 2nd harmonic).

Note that to the peak might look significant but bear in mind the graph is zoomed in on the noise floor. Meaning the peak is only 10 dB above the noise floor of the +40 dB op amp.

I have ordered CPC connectors. I got standard shell size 11-9 pin receptacles, plugs, cable clamps, male and female crimp pins and the insertion tool (see TE Connectivity 206485-1 plug and associated datasheet for compatible parts).

This should make projects a whole lot easier ...

UPDATE:

With a 100 ohm / 100 uF filter separating the Mosfet supply from the op amp supply, there is absolutely no detectable peak at all. I don't suppose this is surprising. But it is a little surprising that it remains true even when using one ground for everything. And I adjusted the Mosfet circuit and increased the stim to dump even more current into the ground. Without the bypass, I completely rebuilt the test circuit twice and even tried adding a 3rd ground conductor for the op amp but I could not best the 10 dB peak.

So I guess the moral of this story is that, in practice, as long as anything that uses a significant amount of power is properly bypassed / buffered, one single ground would be just fine. But knowing that using a separate ground for the "quiet" ground yields a 20+ dB improvement in ground noise, I will probably settle on 3 ground conductors:

1) Shield Ground - for chassis and shields of cables and similar

2) Quiet Ground - for inputs and voltage references and other sources of very small currents

3) Regular Ground - for everything else

This way, I know that if the circuits being powered are not perfect (this is for DIY after all), the extra conductor does add some significant immunity to ground noise.

Note that none of the above has much if anything to do with ground loops. That is an entirely separate issue that has not been tested and ground loops could be a serious issue with such long ground wires. Personally, I have always tried to just used transformers to isolate grounds because there is always some piece of gear that makes things hum without them. Yes, transformers are expensive. But they are foolproof and they provide the best possible performance.

Aside: Although a strong second place to an input transformer are the

THAT 1200 Series InGenius ICs. Personally I think that for one-off projects, the time spent on building the extra circuitry is not worth the cost of the transformer.

[1] Quant Asylum QA400 with custom transformer isolated in/out front end.