Hello,

I've been reading this board for a while now, and learning a lot, but this is my first time posting. I am working towards building a passive eq based on the pultec schematics on the Gyraf website. I would like to keep it totally passive–my plan is to have a transformer-balanced output that can be plugged into a mic amp for make-up gain.

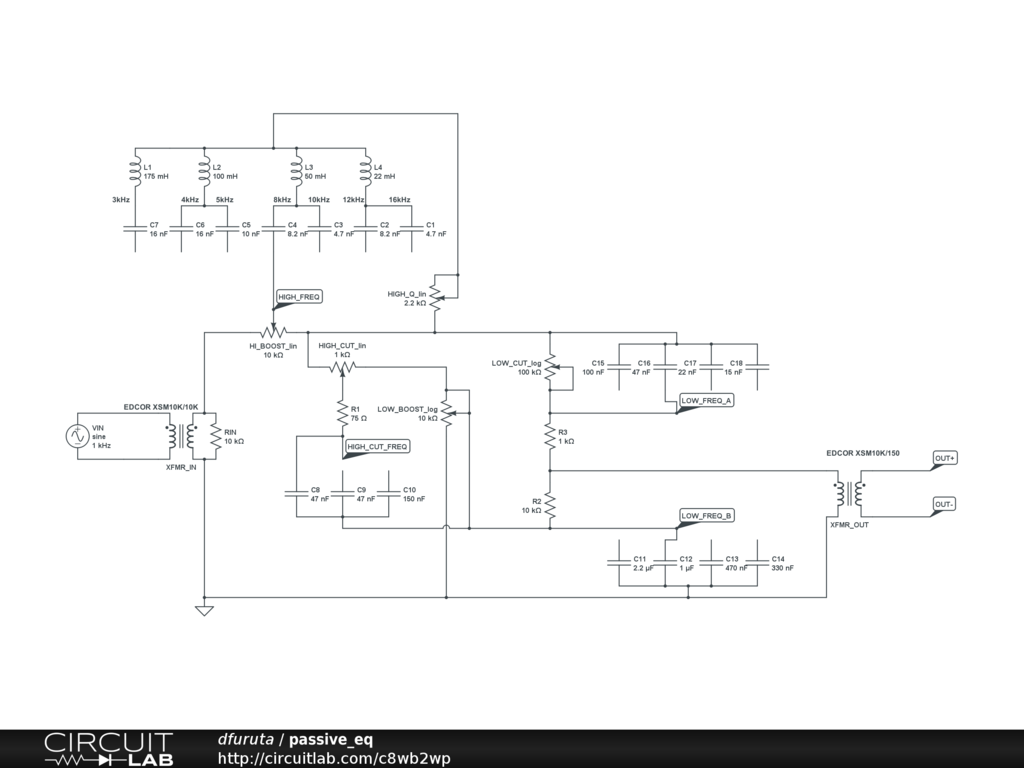

This is what I am planning: this is updated to reflect the conversation below

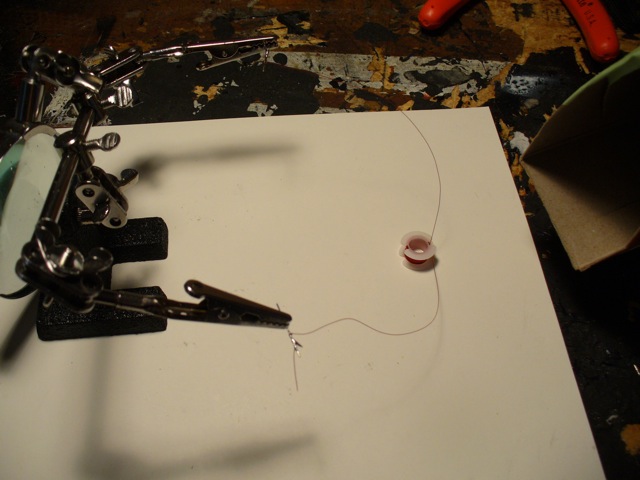

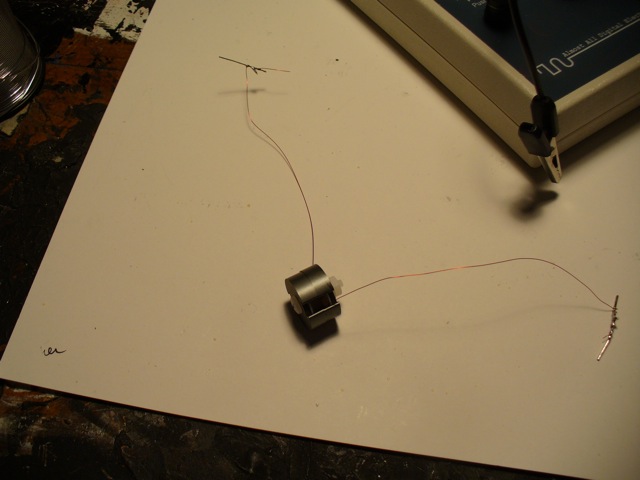

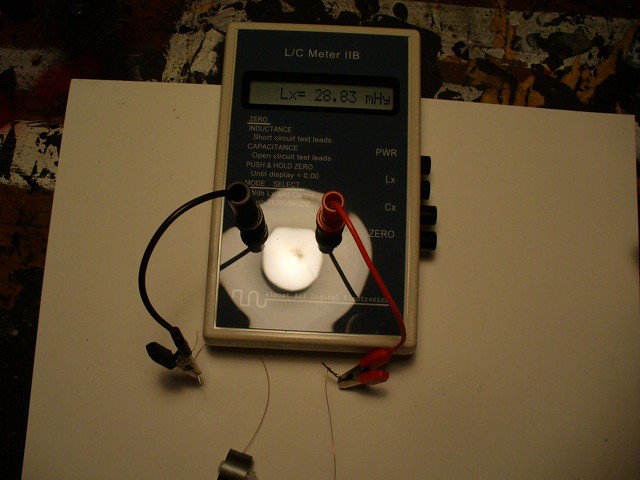

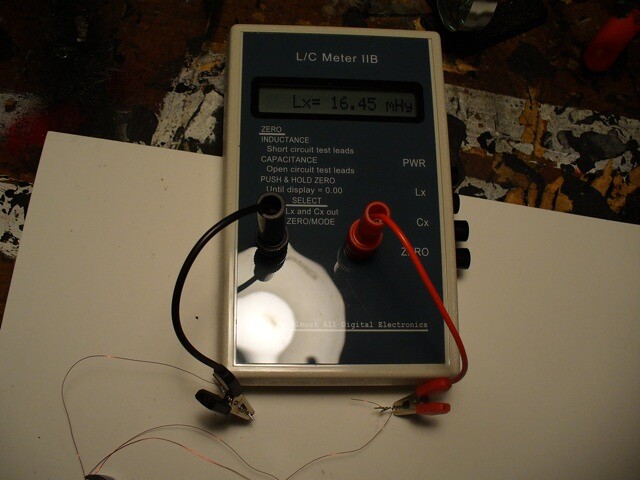

I will be winding the inductors myself. Got that part more or less figured out, at least!

Before I go and drop the money for the components, I wanted to post and see if there are any glaring problems. I'm very much still a student when it comes to electronics, and it's totally possible there's some huge mistake.

If I am correct, this will need around 45dB of gain to get back where it started. This is higher than I'd like, but I'm not sure if there's a way around it while still keeping reasonable input and output impedances. I'm also not sure if a 600 ohm output impedance is a little high to feed into a mic amp.

I would be very grateful for any criticism & critique!

I've been reading this board for a while now, and learning a lot, but this is my first time posting. I am working towards building a passive eq based on the pultec schematics on the Gyraf website. I would like to keep it totally passive–my plan is to have a transformer-balanced output that can be plugged into a mic amp for make-up gain.

This is what I am planning: this is updated to reflect the conversation below

I will be winding the inductors myself. Got that part more or less figured out, at least!

Before I go and drop the money for the components, I wanted to post and see if there are any glaring problems. I'm very much still a student when it comes to electronics, and it's totally possible there's some huge mistake.

If I am correct, this will need around 45dB of gain to get back where it started. This is higher than I'd like, but I'm not sure if there's a way around it while still keeping reasonable input and output impedances. I'm also not sure if a 600 ohm output impedance is a little high to feed into a mic amp.

I would be very grateful for any criticism & critique!