soapfoot

Well-known member

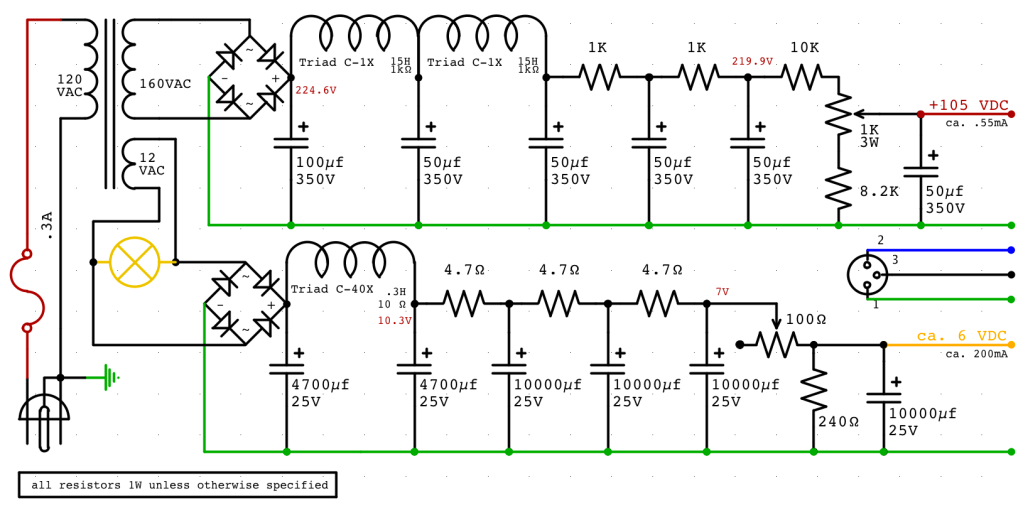

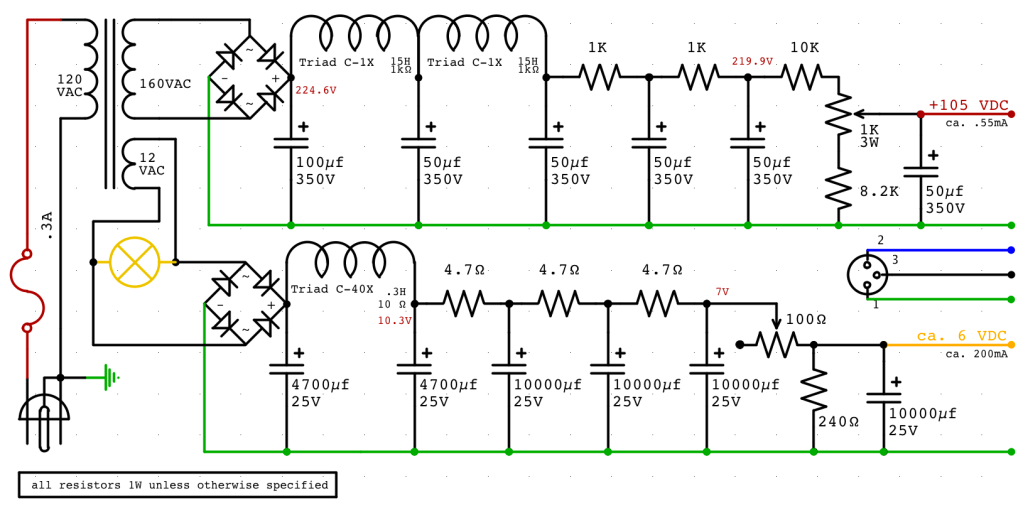

OK, how about this?

Now I might be off-base, but I thought it was good to keep the impedance down in the supply rail so that fluctuations in current didn't cause the power supply to sag, correct?

Would a high resistance in the voltage divider cause the supply to sag under load? Of course we're dealing in fractions of mA here so it practically probably wouldn't be a big deal, right?

Anyway, I went with 10K and 8k2, and used a 1K trimmer. That's a compromise that puts power dissipation at about 1.5W for most settings, which with a 3W trimmer should be fine, right?

Now I might be off-base, but I thought it was good to keep the impedance down in the supply rail so that fluctuations in current didn't cause the power supply to sag, correct?

Would a high resistance in the voltage divider cause the supply to sag under load? Of course we're dealing in fractions of mA here so it practically probably wouldn't be a big deal, right?

Anyway, I went with 10K and 8k2, and used a 1K trimmer. That's a compromise that puts power dissipation at about 1.5W for most settings, which with a 3W trimmer should be fine, right?