soapfoot

Well-known member

Pretty relevant to many of our interests here... I discovered them by googling. They specialize in short runs of custom enclosures for electronics projects. I just needed standard steel 2U boxes, but apparently they can do all kinds of crazy stuff.

My results were pretty good-- I'd give them a 9 out of 10 (details below). I wanted to give a review here because they're a company that could come in very hand for some of us here. They have no minimum orders, although prices do get much more attractive when you order multiple pieces.

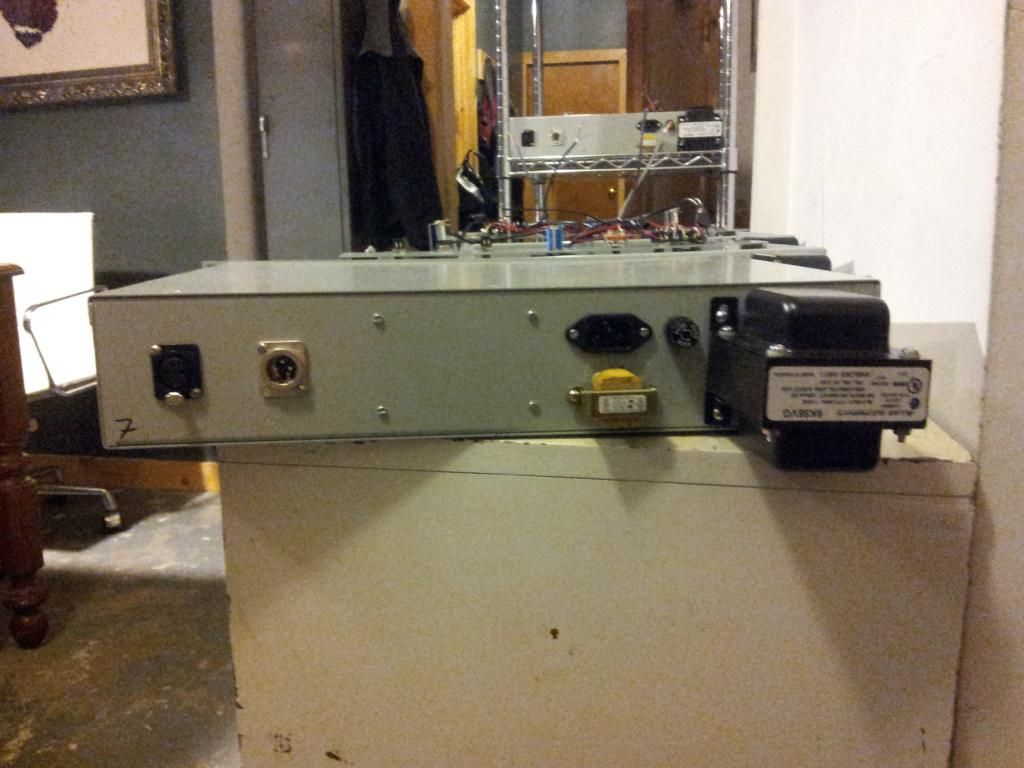

For building 8 REDD mic preamps, I wanted to get a short run of cases made. My front panels had 8 holes, no handles or hinges, gray powdercoat, silkscreening of my design, etc. Very basic. Top panels had vent holes for cooling. Bottom panels had 7 mounting holes for PCB and hardware. Rear panel had 22 holes for various connectors, mounting, etc. Cases were made of cold-rolled steel in their standard gauge, which isn't too thin but isn't super thick either (I forget the exact specs).

They have a lite CAD freeware program including templates for the most common enclosure designs. It was easy to figure out and use, even though I have no prior CAD experience. I laid out everything carefully and double-checked... including silkscreening and powdercoat. They have standard things like Neutrik XLR connectors, IEC connectors, etc. in a cutout library in their CAD software so it made it easier than it could've been.

When I sent in the file to make the order, within a day they had proper mechanical drawings with measurements submitted to me for approval. I found a couple of things that needed to be tweaked, and sent it back for a round of revisions. They were extremely professional and helpful during this phase. Once I approved the mechanical drawings, they sent it off to production and sent me silkscreening proofs to approve. Again, I required one round of revisions, which they did promptly, and that was approved.

Once the silkscreening was approved, my order shipped in one day, which I found impressive. They shipped them to me overnight FedEx from Canada, and that shipping cost was included in the total order price, which was about $1350 for the 8 enclosures, including shipping. There was no extra charge for any of the mechanical drawings or proofs-- that was all included in the order. The $1350 was the "delivered to door" price. It breaks down to about $168 per case with silkscreening and powdercoat all done, all the holes made to my specs, and delivered to my door within a couple of days. I'd say that's pretty fair/decent.

The cases arrived, and initial impressions were mostly positive. I do wish I had gone up a gauge or two on the faceplate, and perhaps the case material as well-- though it should still be robust enough to support the heavy power transformer and other components. There are some indentations that look sort of like knock-outs on the front where the handles would've gone if I'd specified handles-- this isn't the best, but not really a deal breaker. Quality of powdercoat is good.

My biggest quibble isn't a deal breaker-- In two places on the front panel there is text that is in a slightly different location than on the proof... I'm talking about maybe a mm or two off. I had a -34% pad marking under a hole that was centered on the proof, but slightly off-center on the production run. Barely noticeable. I didn't contact them or complain because I didn't deem it worth it.

The most important thing-- every hole I spec'd fit all of my components perfectly. Of course I did my due diligence with datasheets, etc. to make sure everything was right, but... I was VERY impressed that everything was where it was supposed to be, the size it was supposed to be, etc. on the first try, without my ever having done anything like this before. On the fit/mechanical side, they nailed it. On the aesthetic/graphical side, they did "a better than decent job." On the professionalism/interaction/service side, they nailed it.

All in all, I'd use them again, and thought this group might like to know about them.

My results were pretty good-- I'd give them a 9 out of 10 (details below). I wanted to give a review here because they're a company that could come in very hand for some of us here. They have no minimum orders, although prices do get much more attractive when you order multiple pieces.

For building 8 REDD mic preamps, I wanted to get a short run of cases made. My front panels had 8 holes, no handles or hinges, gray powdercoat, silkscreening of my design, etc. Very basic. Top panels had vent holes for cooling. Bottom panels had 7 mounting holes for PCB and hardware. Rear panel had 22 holes for various connectors, mounting, etc. Cases were made of cold-rolled steel in their standard gauge, which isn't too thin but isn't super thick either (I forget the exact specs).

They have a lite CAD freeware program including templates for the most common enclosure designs. It was easy to figure out and use, even though I have no prior CAD experience. I laid out everything carefully and double-checked... including silkscreening and powdercoat. They have standard things like Neutrik XLR connectors, IEC connectors, etc. in a cutout library in their CAD software so it made it easier than it could've been.

When I sent in the file to make the order, within a day they had proper mechanical drawings with measurements submitted to me for approval. I found a couple of things that needed to be tweaked, and sent it back for a round of revisions. They were extremely professional and helpful during this phase. Once I approved the mechanical drawings, they sent it off to production and sent me silkscreening proofs to approve. Again, I required one round of revisions, which they did promptly, and that was approved.

Once the silkscreening was approved, my order shipped in one day, which I found impressive. They shipped them to me overnight FedEx from Canada, and that shipping cost was included in the total order price, which was about $1350 for the 8 enclosures, including shipping. There was no extra charge for any of the mechanical drawings or proofs-- that was all included in the order. The $1350 was the "delivered to door" price. It breaks down to about $168 per case with silkscreening and powdercoat all done, all the holes made to my specs, and delivered to my door within a couple of days. I'd say that's pretty fair/decent.

The cases arrived, and initial impressions were mostly positive. I do wish I had gone up a gauge or two on the faceplate, and perhaps the case material as well-- though it should still be robust enough to support the heavy power transformer and other components. There are some indentations that look sort of like knock-outs on the front where the handles would've gone if I'd specified handles-- this isn't the best, but not really a deal breaker. Quality of powdercoat is good.

My biggest quibble isn't a deal breaker-- In two places on the front panel there is text that is in a slightly different location than on the proof... I'm talking about maybe a mm or two off. I had a -34% pad marking under a hole that was centered on the proof, but slightly off-center on the production run. Barely noticeable. I didn't contact them or complain because I didn't deem it worth it.

The most important thing-- every hole I spec'd fit all of my components perfectly. Of course I did my due diligence with datasheets, etc. to make sure everything was right, but... I was VERY impressed that everything was where it was supposed to be, the size it was supposed to be, etc. on the first try, without my ever having done anything like this before. On the fit/mechanical side, they nailed it. On the aesthetic/graphical side, they did "a better than decent job." On the professionalism/interaction/service side, they nailed it.

All in all, I'd use them again, and thought this group might like to know about them.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)