There’s a couple of YouTube vids showing using a ratcheted band strap tie-down around the tank and setting the ratchet body position - when you turn the bolt there is a timber brace going to the wall from the ratchet head in line with the tangent to the tank face and thus the line of force - all you need is a spreader plate on the flat of the wall between studs so the brace doesn’t punch a hole. Those tie-downs are what are used to tie cars down to tow trucks with a 2” wide strap - if the strap slips you can always run a band of double sided tape around the circumference of the tank under the strap to prevent this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Klein tools

- Thread starter Brian Roth

- Start date

Help Support GroupDIY Audio Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

That sounds easy...

=====

Yup, I already tried the ratchet strap... but do not have a robust section of wall handy to brace it against.. This sucker is really stuck in there.

This heater is already several years old so I will wait for it to fail... My last one started giving me electrical shocks in the shower... now I have attached a ground wire to the tank, and another to the copper pipes.

JR

=====

Yup, I already tried the ratchet strap... but do not have a robust section of wall handy to brace it against.. This sucker is really stuck in there.

This heater is already several years old so I will wait for it to fail... My last one started giving me electrical shocks in the shower... now I have attached a ground wire to the tank, and another to the copper pipes.

JR

Maybe wear a ground-strap in the shower just to be sure

Shock me once shame on you, shock me twice shame on me...Maybe wear a ground-strap in the shower just to be sure

My hot water heater is grounded by two different paths. The metal tank is grounded to my fuse panel, and the copper plumbing is separately grounded, so I feel pretty safe.

JR

My hot water heater is grounded by two different paths. The metal tank is grounded to my fuse panel, and the copper plumbing is separately grounded, so I feel pretty safe.

Well... um ... ahem ... Is that really the best approach? I kinda almost believe the NEC requires a common, bonded, single-point grounding scheme; running separate grounds is generally contraindicated. For example, my radio station is bonded to the domestic mains grounding scheme. I would never run a separate ground not bonded to the mains ground scheme. OR, do I misunderstand what youi mean by "separate ground?"

Disclaimer: Of course, I may be totally corn-fused and off base, but the notion of separate grounds sorta, kinda, almost seems a bad idea, remembering what I have read in the NEC, the ARRL Grounding Book, and materials from Lightning Protection Institute (yeah I know there are different types and reasons for grounding different stuff) and I am certainly NO expert, so I merely raise the point as a question, not a statement. Sue me if I am speaking out of turn.

Either one of the two grounds should be protective against a fault like the one I encountered years ago when the heater box rusted through and energized my hot water supply.Well... um ... ahem ... Is that really the best approach? I kinda almost believe the NEC requires a common, bonded, single-point grounding scheme; running separate grounds is generally contraindicated. For example, my radio station is bonded to the domestic mains grounding scheme. I would never run a separate ground not bonded to the mains ground scheme. OR, do I misunderstand what youi mean by "separate ground?"

Disclaimer: Of course, I may be totally corn-fused and off base, but the notion of separate grounds sorta, kinda, almost seems a bad idea, remembering what I have read in the NEC, the ARRL Grounding Book, and materials from Lightning Protection Institute (yeah I know there are different types and reasons for grounding different stuff) and I am certainly NO expert, so I merely raise the point as a question, not a statement. Sue me if I am speaking out of turn.James

My hot water heater is one of the few appliances grounded in my red neck wiring house. I also DIY grounded the GFCI outlet supplying my dishwasher and washing machine.

I had lightning strike a tree about 40' from my bedroom window (loud). It blew a transistor in my crawl space sump pump controller.

JR

Brian Roth

Well-known member

NEC "code" is quite clear about bonding "grounds". Utility power, metal water and gas pipelines (and in larger building..... internal metal structures) SHALL be bonded together.

The silly concept of "Well, lets just connect all of the grounding for the studio into a separate grounding rod in the backyard and have no connection to utility ground" is dangerous and NOT "to NEC code".

Bri

The silly concept of "Well, lets just connect all of the grounding for the studio into a separate grounding rod in the backyard and have no connection to utility ground" is dangerous and NOT "to NEC code".

Bri

Brian Roth

Well-known member

@JohnRoberts

I'm certain you know how the utility system is connected into your hacienda....do you have a grounding rod in the dirt where "Hickory Power" has their service entrance?

Bri

I'm certain you know how the utility system is connected into your hacienda....do you have a grounding rod in the dirt where "Hickory Power" has their service entrance?

Bri

yes.@JohnRoberts

I'm certain you know how the utility system is connected into your hacienda....do you have a grounding rod in the dirt where "Hickory Power" has their service entrance?

Bri

===

The redneck aspect of my house wiring is the absence of grounded 3 wire outlets.

JR

Brian Roth

Well-known member

Mom's house was like that as well. This little house in Kansas is a mixture of 2 and 3 prong outlets. BUT I know where the grounding rod from Evergy is (below the meter) as well as the bonding into the metal water and gas pipes are.

Bri

Bri

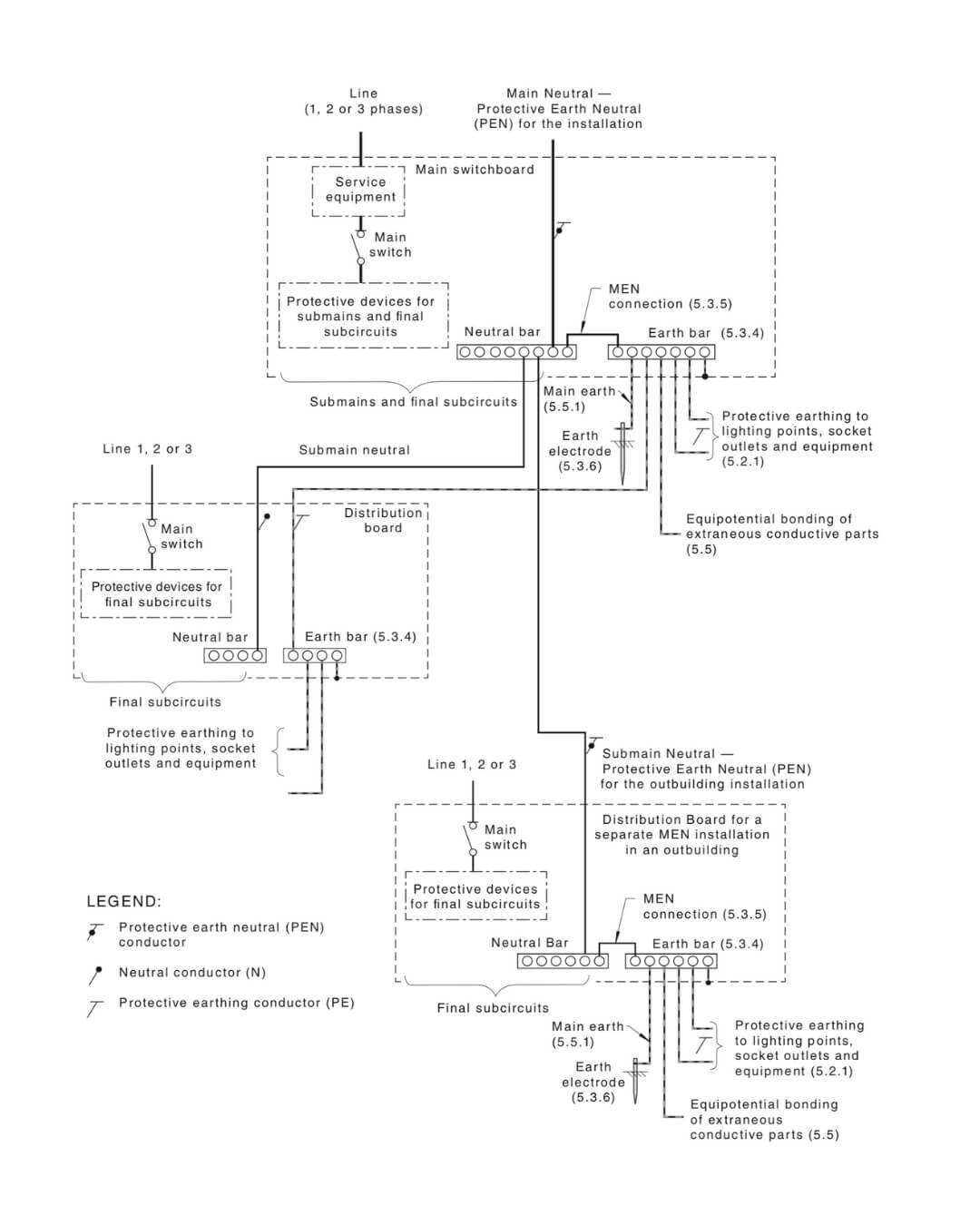

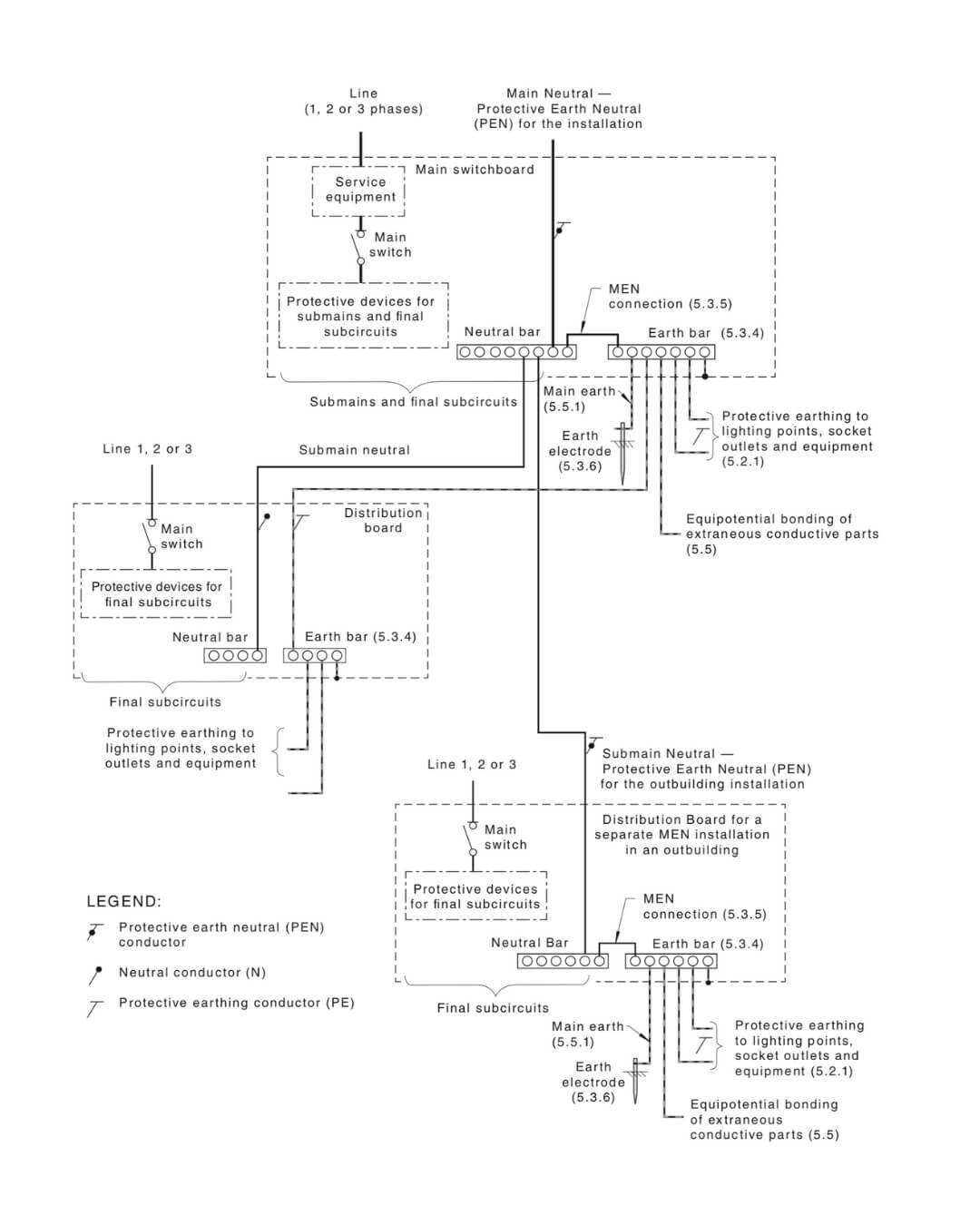

We use a MEN System here - (Multiple Earth Neutral). Every outlet is 3 pin - there are no 2 pin outlets. There are 20A outlets that have a larger earth pin, so any equipment rated over 10A with a 20A plug can’t plug into a normal domestic socket.

Every main and sub main board has an earth rod in the ground and earth is connected to neutral at each board.

Every main and sub main board has an earth rod in the ground and earth is connected to neutral at each board.

Did you never try the automatic centre punch technique to shock the screw into loosening a bit. Used at an angle on the edge of the screw in the direction to undo the screw this has been quite effective for me. It's only ever a last resort putting a slot in the top for me.John...."stuck machine screws" reminds me of several MCI JH-636 desks I used to service. They used 6-32 button hex heads to secure the modules to the frame. I guess the screws became imbedded into the paint on the front panels. Even with "fresh", high quality hex keys the screw heads usually stripped out.

Dremel tool and a thin cutting wheel to create a slot and then use a flat head screwdriver to finally bust the screw loose so the module(s) could be removed. Fred Flintstone service engineering...I hated doing that.

Bri

Brian Roth

Well-known member

Rob, it's been decades since I had that "battle" with MCI modules. I'll try your suggestion if I encounter the problem again. Thanks!

Bri

Bri

scott2000

Well-known member

Just came across this video...A powered anode rod...Supposed to keep sediment away too. Maintenance free water heater ?20 year warranty?I have a sacrificial anode in my hot water heater that I gave up trying to break loose. I decided to replace it before it was barely 2 years old but no luck.

4:47 he gets into it

Brian Roth

Well-known member

LOL! In another thread on the forum here, I was asking about circuit breaker finders after my "Sperry" branded one died. I can buy this Klein setup (made in China) locally:

https://www.kleintools.com/catalog/...tal-circuit-breaker-finder-gfci-outlet-tester

I have a bunch of outlets and breakers at Blue Heaven Studios with no labels....

Bri

https://www.kleintools.com/catalog/...tal-circuit-breaker-finder-gfci-outlet-tester

I have a bunch of outlets and breakers at Blue Heaven Studios with no labels....

Bri

I actually bought one of those (active powered anodes, from a different company) years ago when my water heater was still relatively new.Just came across this video...A powered anode rod...Supposed to keep sediment away too. Maintenance free water heater ?20 year warranty?

4:47 he gets into it

The problem is that it screws into the hole where the standard sacrificial anode comes out of.... BUT I have not been able to get my old sacrificial anode out.

I banged on it with both a puny electric impact wrench for a couple hours, and then with a real compressed air powered impact wrench for several hours.

I have a sturdy breaker bar with a steel pipe torque amplifier, but I needed to strap the tank down to keep it from twisting. There is nothing robust enough to secure it to nearby. About the only thing I didn't try was heating it up with an acetylene torch.

I still have the powered anode sitting in a box by my water heater, if I live long enough to buy another new water heater. I am probably more than half way there (8-12 years average life).

JR

PS: Just thinking about this again makes me angry.

Brian Roth

Well-known member

PS: Just thinking about this again makes me angry.I can't read minds like some here, but I doubt that the water heater manufacturers lose sleep when these anodes are impossible to remove.

Perhaps they are actually welded in place? "No user serviceable parts inside."

Bri

scott2000

Well-known member

I hear electric ones can last 20 or more years with maintenance... Guess the sediment can build up and submerge the lower element which creates the first issue. And keeping the anode fresh...idk(8-12 years average life

Did you ever post a picture of your setup? Maybe others here can see a solution for the strap? But yeah, I've had to use an actual 5ft piece of fence post from a chain link fence to remove a stubborn axle nut in the past where shorter cheater pipes and less than stellar impacts didn't work. Really would love to try one of those Milwaukee Fuel battery impacts.

Last edited:

My original one was probably many years older than 20. When it failed the heating element containment had rusted through and energized my hot water supply. I literally felt a tingle when testing the water temp before taking a shower.I hear electric ones can last 20 or more years with maintenance... Guess the sediment can build up and submerge the lower element which creates the first issue. And keeping the anode fresh...idk

I gave up on that a few years ago. I tried a tie down strap to wrap around the water tank. I think my last attempt involved a 2x4 as a strut but I stopped that when it looked like it would punch a hole through my laundry room wallboard.Did you ever post a picture of your setup? Maybe others here can see a solution for the strap?

I bought a mains powered impact wrench and it was a joke.But yeah, I've had to use an actual 5ft piece of fence post from a chain link fence to remove a stubborn axle nut in the past where shorter cheater pipes and less than stellar impacts didn't work. Really would love to try one of those Milwaukee Fuel battery impacts.

===

Last night my overnight team thought of (remembered) a different strategy... Perhaps I could figure out how to feed the active anode in through the hole where the pressure relief screws in, or the drain hose. I would need to do some plumbing to restore those features. I already had to replace the pressure relief valve when it was dripping several years ago.

JR

This looks interesting...

A little simple plumbing, adding a T and rt angle allows dropping the active anode (that I already have sitting in a box) in through the top hot water outlet port. This could rescue my current hot water heater whose sacrificial anode is surely already toast.

===

For good measure I connected a hose and drained some rusty water out of the hot water heater. It wasn't that bad, but I probably drained it about a year ago.

JR

A little simple plumbing, adding a T and rt angle allows dropping the active anode (that I already have sitting in a box) in through the top hot water outlet port. This could rescue my current hot water heater whose sacrificial anode is surely already toast.

===

For good measure I connected a hose and drained some rusty water out of the hot water heater. It wasn't that bad, but I probably drained it about a year ago.

JR

Similar threads

- Replies

- 34

- Views

- 2K

- Replies

- 3

- Views

- 408