Hi Boji,

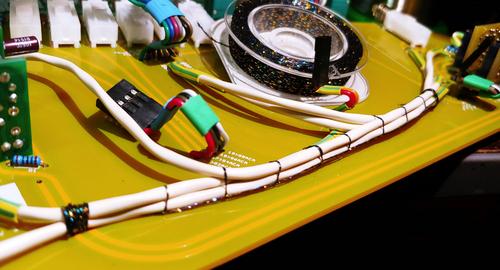

If you ever had the opportunity to visit an old time Strowger telephone exchange (like those made by GEC in the UK), the cable lacing done there was a work of art and something to behold. Often with up to a hundred twisted pair cables in a loom, the cables had to be perfectly placed with respect to each other and the gap between each knot had to be at a specific distance according to the diameter of the loom. Each tail, as it was called had to come out as just the right angle. There is also a special knot that has to be pulled tight so that each loop of the loom was self sufficient and I still have the groove scar in my fingers from pulling the waxed string knot tight. The looms were made up on a type of peg board by very skilled women and sometime by apprentices like me.

I have seen a QC manager inspect a loom and go down the knots with cutters because the distance between the knots was wrong. He would use a ruler to measure them - boy he was hard!

Incidentally, the loom of blue cables shown on the web site you gave would fail QC, because if one knot failed, the whole loom could unravel. From what I remember, figure C is the closest to the knot used.

Cheers

Mike