When I was a student engineer working in the local railway authority, I was posted to various places in the 'running sheds' where the various trades people and some engineers would refurb the 'rolling stock' ... electric rail cars used in urban and inter-urban services.

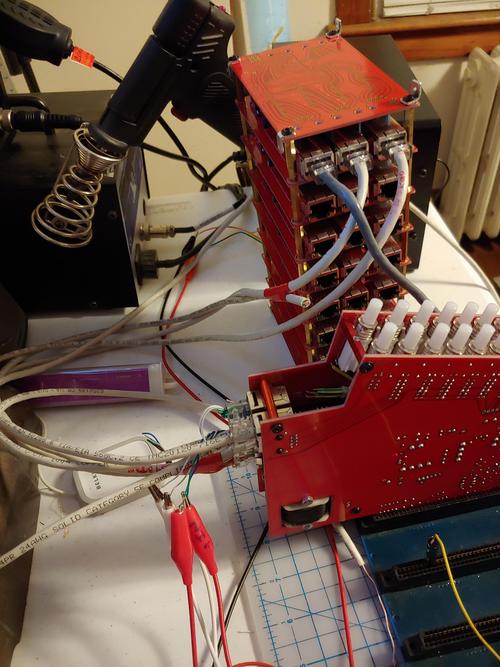

Well, even a plain electric rail car with overhead pantograph power has a tremendous amount of wiring, terminating areas and switching relays to the max.

They all had the large blue print plans to their 'wiring' and they knew exactly what they were doing.

To me, at 18yrs old and still coming to terms with getting up at 5am, it seemed incredible - more like 'knitting' and 'crochet' of what appeared to be dozens of wiring looms, each being bundles of 50 or so serious current 'control distribution' wires.

Everyone properly terminated, identified with special tagging collars (labelling) .. and running the full length of the car to the couplings, and all the local functions, doors, alarms, hydraulic monitors, etc etc.

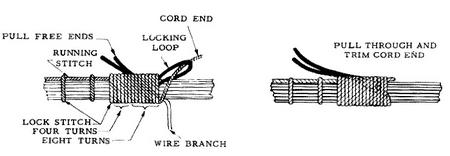

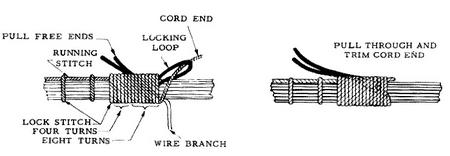

And the stitched it all up in these beautiful looms .. mechanically robust, immobilized for heavy duty environments and so on.

Amazing stuff, and they did it mostly lying down or on their backs .. sometimes sitting comfortably at the junction boxes .. with peak concentration in the early morning cold.

Just working thru the blueprints for any given 'circuit' was a challenge, to my fresh out of high school eyes ???

...

But yes - the art of loom assembly and commisioning is a great art of the electrical people!