Im not trying to argue that for most purposes a diagonal splice will be more appropriate .

In some cases a diagonal cut just isnt appropriate like for instance if you wanted to edit parts on 2 inch tape , likewise editing a stereo recording at the start and finish where theres silence youd mostly go with diagonal, If you were editing the music itself Id say straight cut is most appropriate . As I said previously the quality of the result you get in any case is down to technique and materials ( good hands, good sticky tape ,good block ,good blade).

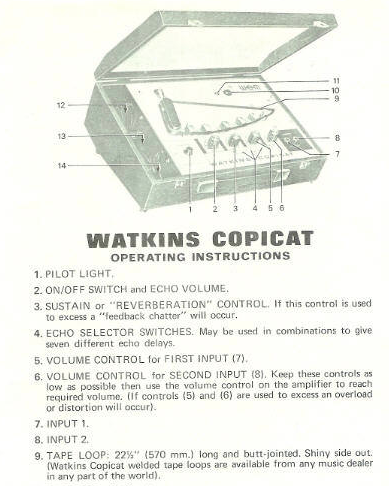

What Ive personally found with the copicat is diagonal splices tend to open up after a while , the capstan has a very narrow diameter so the tape has to go around a tight radius and the entire tape loop remains under tension at all times .

I did quite a bit of 1/4 inch tape editing back in the mid 90's , mostly adding lead-in and lead-out sections in green and red respectively , but also some musical edits . Im not really sure how the rotary head digital machines come into the discussion about tape editing , as far as I know formats like that arent editable . Just as an example an ADAT tape uses the rotary head type set up , I never heard of anyone trying to cut or splice those. The Sony Dash multitrack recorders had stationary heads, I never worked with those machines but again I never heard of anyone trying to edit the tapes either.

Anyway just my thrupence worth , we wont fall out over it

I might dig out my copy of 'Sound Recording Practice' later and see what the APRS had to say on the matter .

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)