owel

Well-known member

I need to mill rear panels for a new 2 channel case for this upcoming puppy.

Startup PC, using Mach3 software with an eBay D.I.Y. CNC machine. Yup, it's a touchscreen LCD.

PC also has a wireless network card. I pull up the g-code files from my network drive.

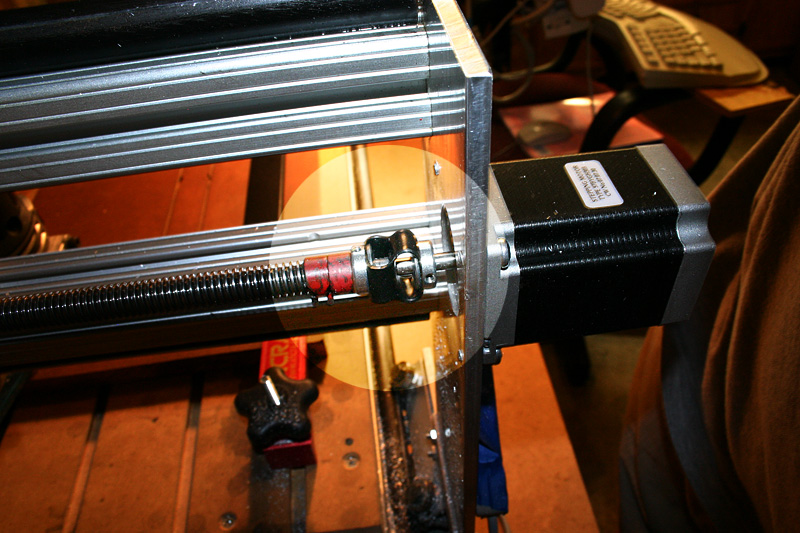

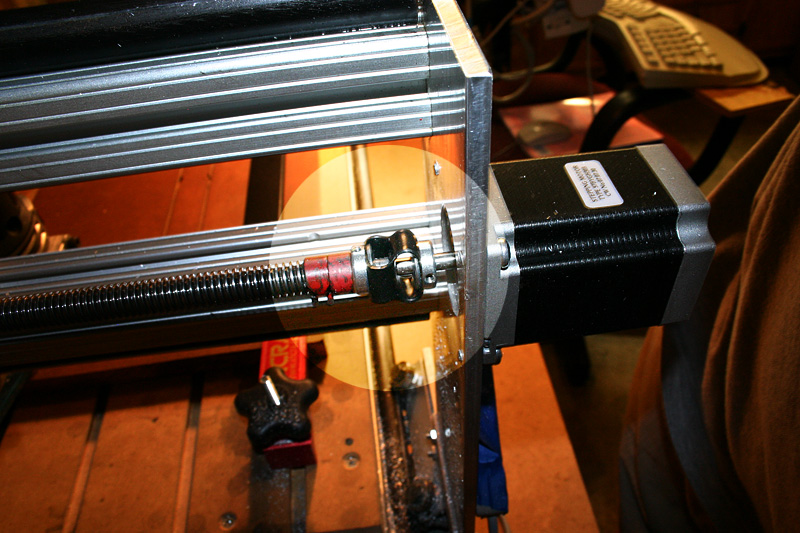

I did some mods to the machine, replacing the coupling with this thingy... it reduced vibration and made the cuts smooth as butter.

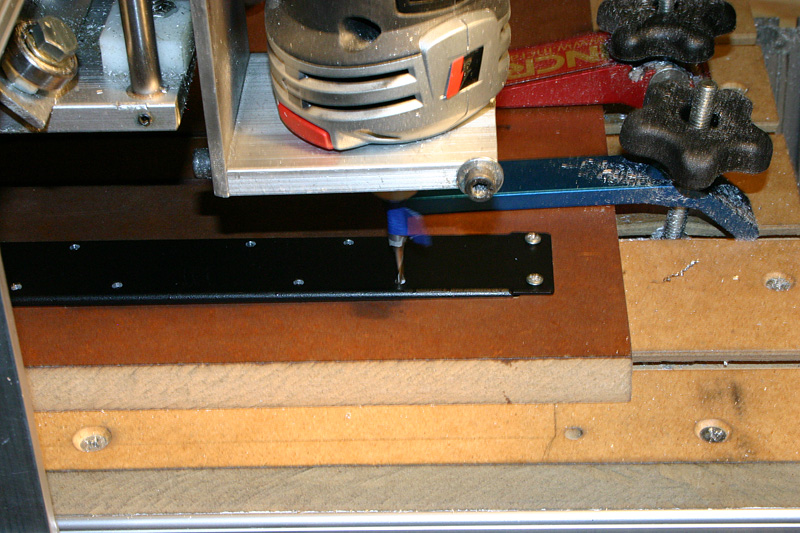

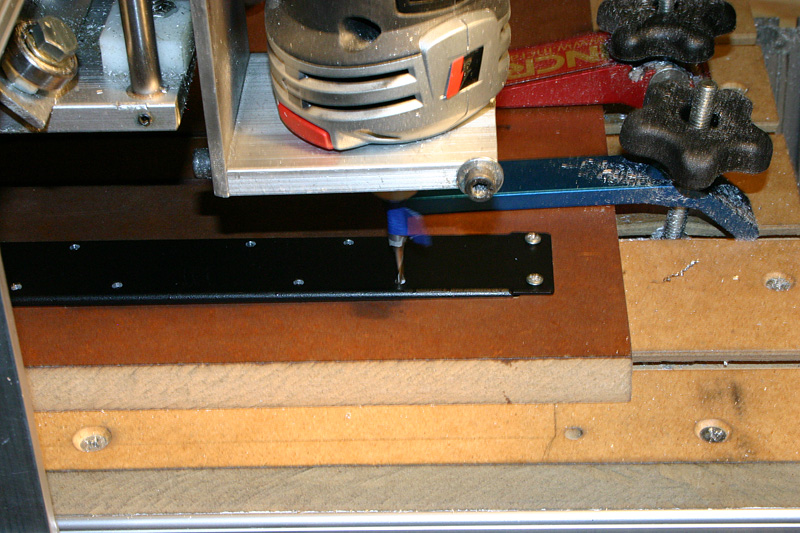

Brand new G-code, running it for the first time. All seems well... Drilling holes for the XLR jacks.

Yup, that's a blue painters tape you see on the pic above. It's my "fan" so it blows the shards away from the workpiece. (Someday, I hope to have a vacuum attachment)

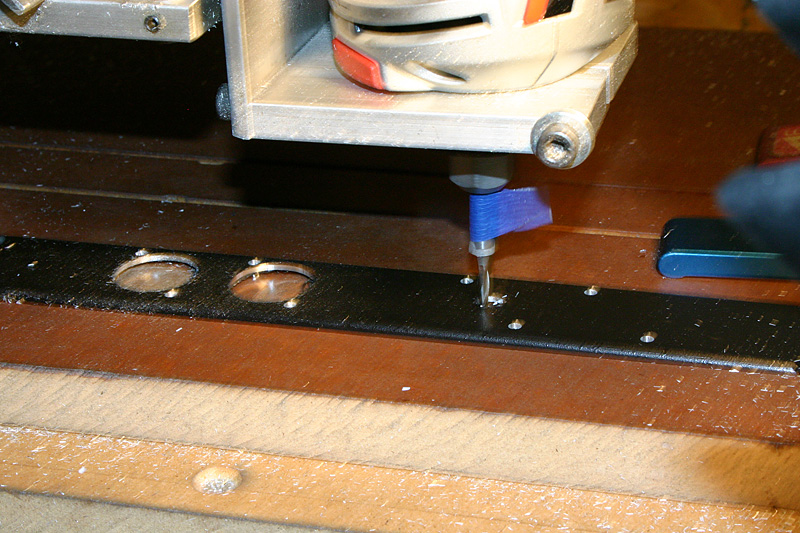

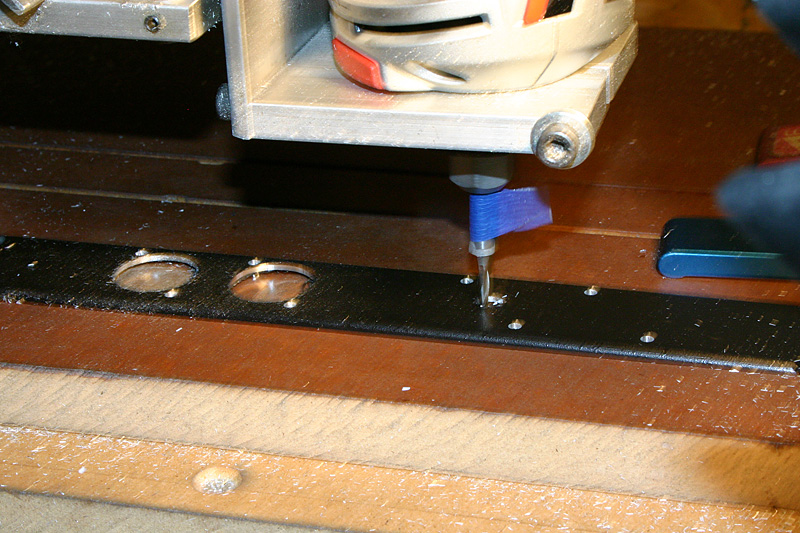

Now, it's milling the XLR holes. Forgive the picture, that's my unsteady hand. (but it seems to look like the workpiece is vibrating)

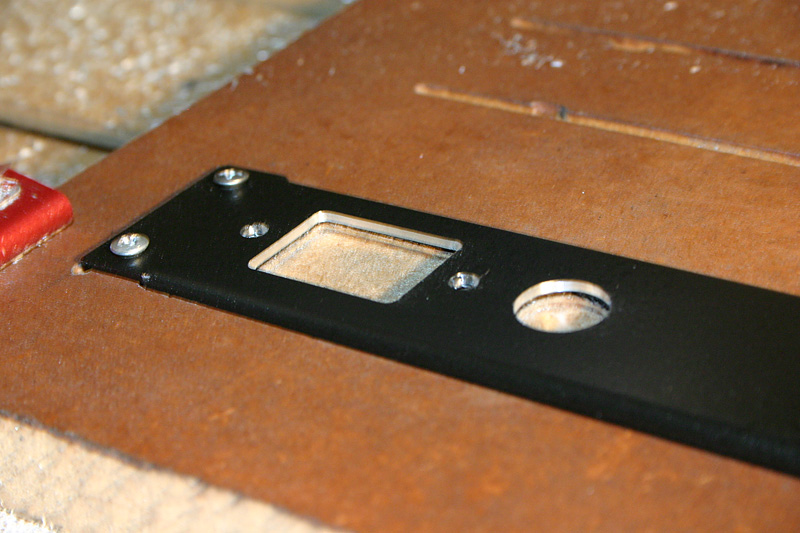

Now, it's creating the hole for the fuse holder.

then the IEC AC inlet connector...

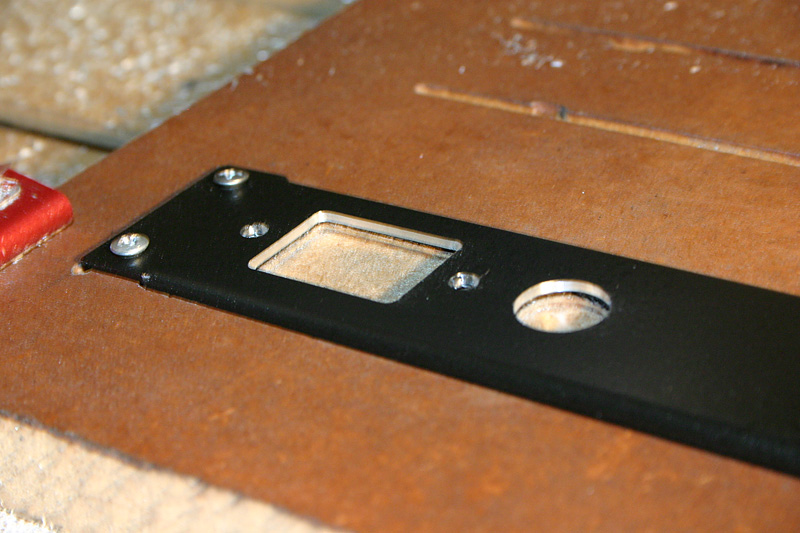

and we're done!

I'm only running at 4IPS since I do not have a heavy duty motor and not running coolant. Plus I like my cut smooth so I don't want to be in a hurry.

All in all, it took about 30+ minutes. I can leave it running while I go do something else so the "slow" speed doesn't bother me.

Beats using a drill press and manual filing!

Startup PC, using Mach3 software with an eBay D.I.Y. CNC machine. Yup, it's a touchscreen LCD.

PC also has a wireless network card. I pull up the g-code files from my network drive.

I did some mods to the machine, replacing the coupling with this thingy... it reduced vibration and made the cuts smooth as butter.

Brand new G-code, running it for the first time. All seems well... Drilling holes for the XLR jacks.

Yup, that's a blue painters tape you see on the pic above. It's my "fan" so it blows the shards away from the workpiece. (Someday, I hope to have a vacuum attachment)

Now, it's milling the XLR holes. Forgive the picture, that's my unsteady hand. (but it seems to look like the workpiece is vibrating)

Now, it's creating the hole for the fuse holder.

then the IEC AC inlet connector...

and we're done!

I'm only running at 4IPS since I do not have a heavy duty motor and not running coolant. Plus I like my cut smooth so I don't want to be in a hurry.

All in all, it took about 30+ minutes. I can leave it running while I go do something else so the "slow" speed doesn't bother me.

Beats using a drill press and manual filing!

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)