owel

Well-known member

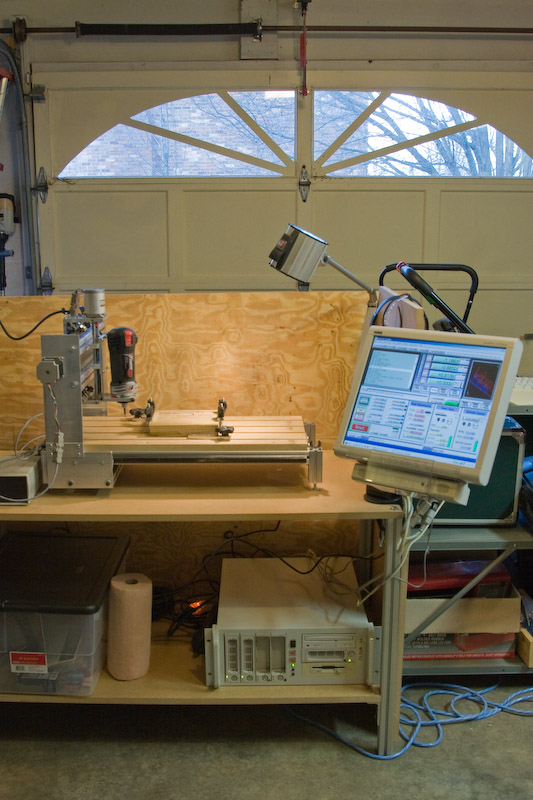

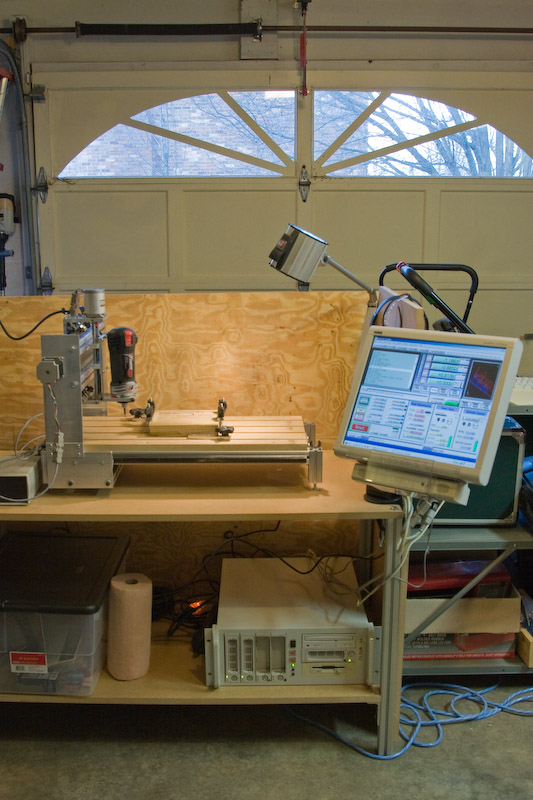

After a few months of planning, setup, purchasing and learning, my CNC machine is now up and running.

Sample of a .06" Aluminum, drilled and milled for IEC AC inlet jack, fuse holder, XLR jacks. Man... everything fits in the hole so perfectly.

The machine bed is 12" x 24" so it's big enough to mill 19" wide panels. The rotozip and whole assembly is rigid enough to mill thick aluminum typically used in case panels.

Using an 18" NEC LCD Touchscreen on movable arms! CNC Computer has wireless connectivity to the LAN/Internet.

I'm using SheetCam (thanks to another Prodigy member for that software tip) and Mach3.

Next goal: Fine text engraving and 3D countour milling so I can have front panels a'la Grace or Focusrite Reds.

Sample of a .06" Aluminum, drilled and milled for IEC AC inlet jack, fuse holder, XLR jacks. Man... everything fits in the hole so perfectly.

The machine bed is 12" x 24" so it's big enough to mill 19" wide panels. The rotozip and whole assembly is rigid enough to mill thick aluminum typically used in case panels.

Using an 18" NEC LCD Touchscreen on movable arms! CNC Computer has wireless connectivity to the LAN/Internet.

I'm using SheetCam (thanks to another Prodigy member for that software tip) and Mach3.

Next goal: Fine text engraving and 3D countour milling so I can have front panels a'la Grace or Focusrite Reds.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)