rock soderstrom

Tour de France

Hi guys

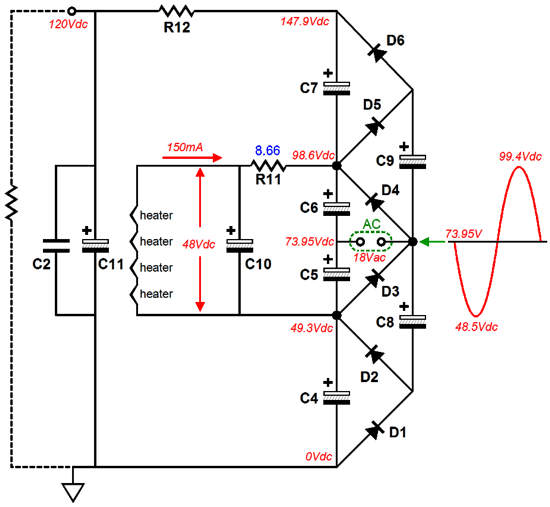

I have sketched a power supply based on a voltage multiplier for the first time.

The goal is to provide a flexible solution for tube microphones with transformers that are not dedicated tube transformers. I have numerous small 17V/8VA toroidal transformers that I would like to use for projects such as Sela T12, Royer mod or even Gyraf G7. Conceivable would be also 12V to 24V transformers, what one has available.

The Villard-Grainacher circuit provides taps from X2 to X6 which should then be routed via jumper to the filter section, as needed.

The heating is obtained from the same transformer, the thermal load is to be distributed to a large series resistor, the cooled LM317 and another filter resistor. The goal is a clean voltage of 4-12.6V.

Does this work as intended? What do you think? Ok, overkill or nonsense?

Cheers

Edit: intented for self etch PCBs. One will only populate what is needed

I have sketched a power supply based on a voltage multiplier for the first time.

The goal is to provide a flexible solution for tube microphones with transformers that are not dedicated tube transformers. I have numerous small 17V/8VA toroidal transformers that I would like to use for projects such as Sela T12, Royer mod or even Gyraf G7. Conceivable would be also 12V to 24V transformers, what one has available.

The Villard-Grainacher circuit provides taps from X2 to X6 which should then be routed via jumper to the filter section, as needed.

The heating is obtained from the same transformer, the thermal load is to be distributed to a large series resistor, the cooled LM317 and another filter resistor. The goal is a clean voltage of 4-12.6V.

Does this work as intended? What do you think? Ok, overkill or nonsense?

Cheers

Edit: intented for self etch PCBs. One will only populate what is needed

Last edited: