MS Vienna

Well-known member

Hi,

the TLM103´s capsule mounting was the first of it´s kind and a bit unusual. Due to the very simple mechanical construction of the mic (obviously to achieve a low selling price) the capsule is directly mounted on the PCB. The PCB is fixed in the mic´s housing by a rubber ring.

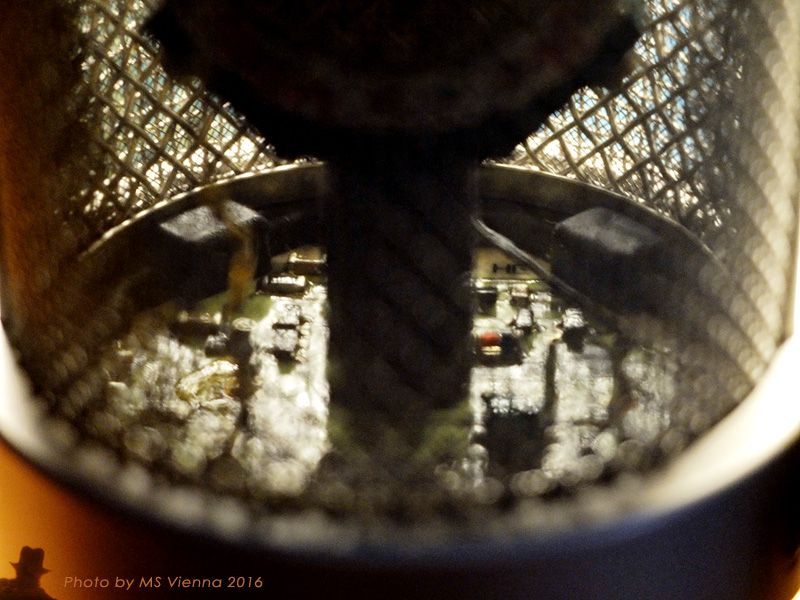

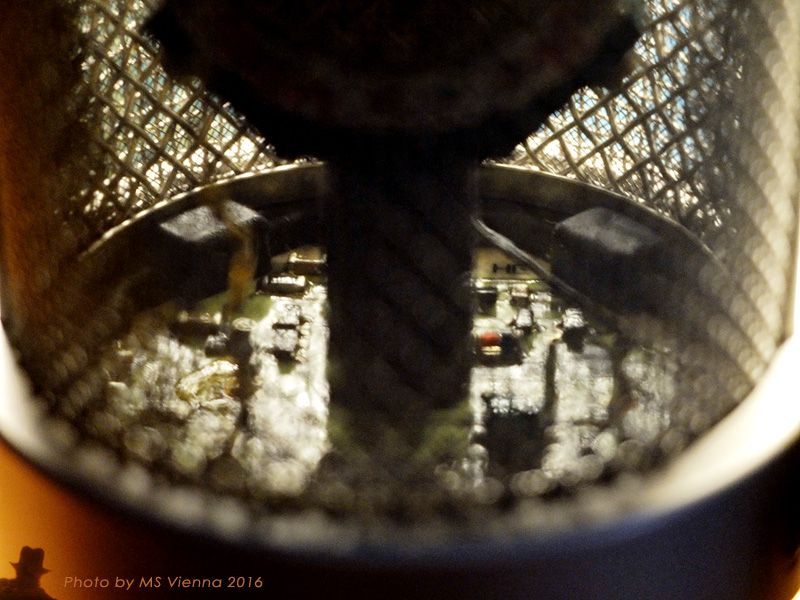

Unlike any Neumann LDC mics before the capsule sits quite low in the grille and sees a slightly unfortunate acoustical environment. While the grillecap is a proven design (U67, U87 and similar) the base plane on which the capsule sits (PCB) is way below the lower grille entry, basically creating a shallow cavity.

I think the TLM103 is a great mic for the money with very low noise and good off axis behaviour. Soundwise it leaves some room for improvement. Since nothing can be really done about the capsule or the electronics (by me), I focused on the acoustical shortcomings inside the grille. I had good success with that on my Brauner VM1 so I was encouraged to give it a go on the 103.

If you do a search for U67 capsule assembly pictures you´ll notice that the capsule stands on a polished plastic dome that acts like a diffusor. That´s what I wanted.

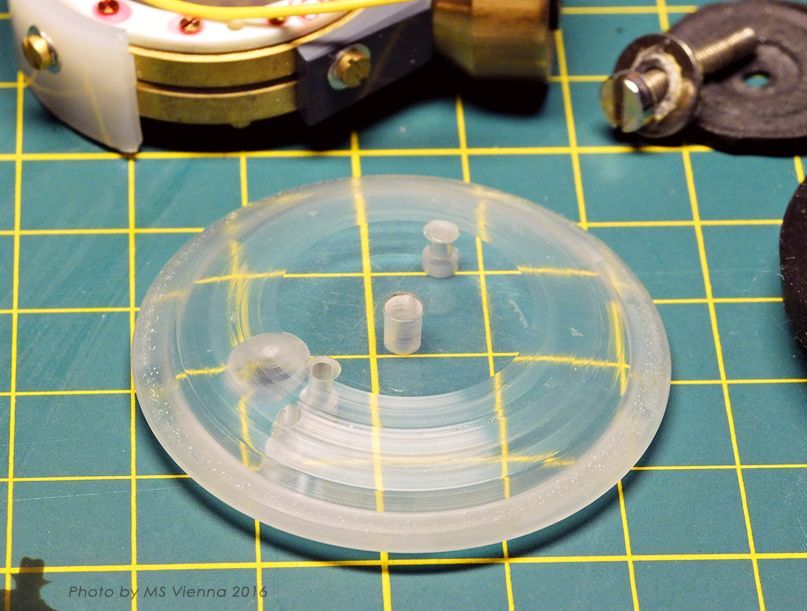

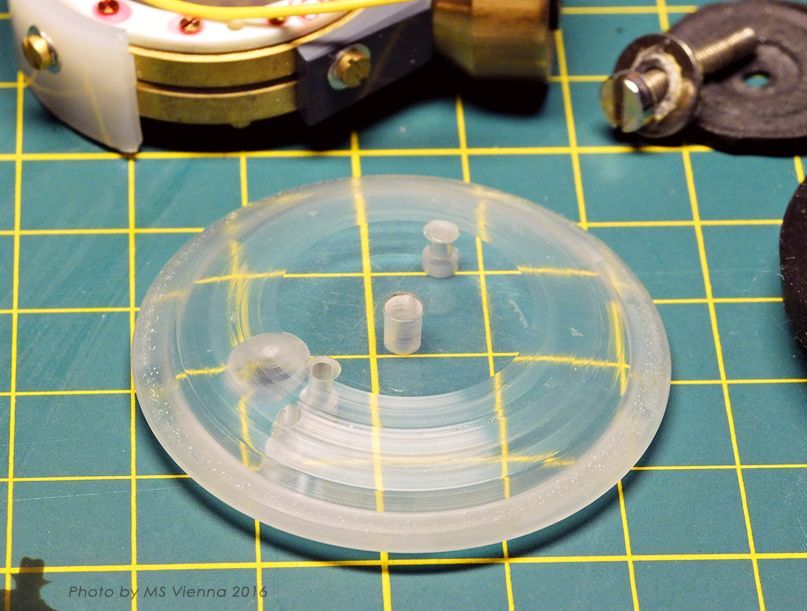

After disassembling and with a piece of Plexiglas that´s gonna become the new capsule base.

BTW the original "elastic" capsule mount isn´t elastic at all...

Plexi base before finishing

For tips how to manufacture this please see this posting:

http://groupdiy.com/index.php?topic=63305.msg802223#msg802223

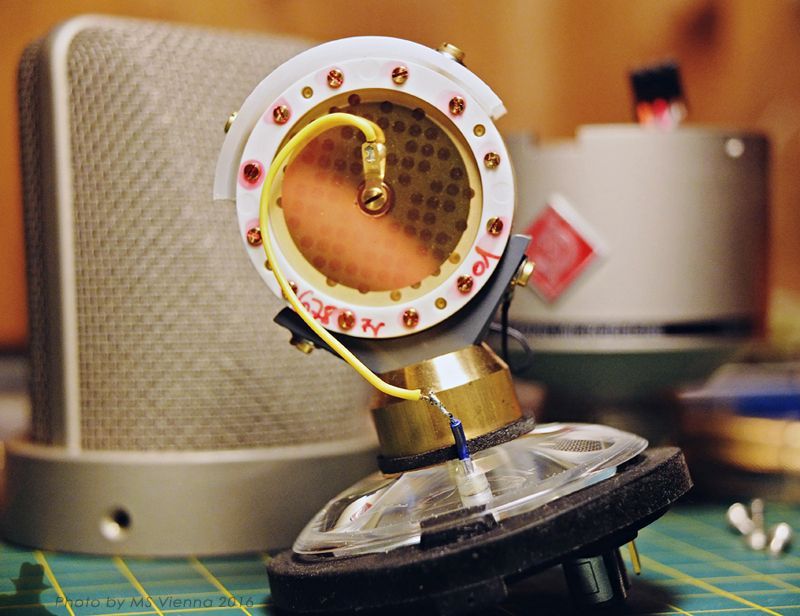

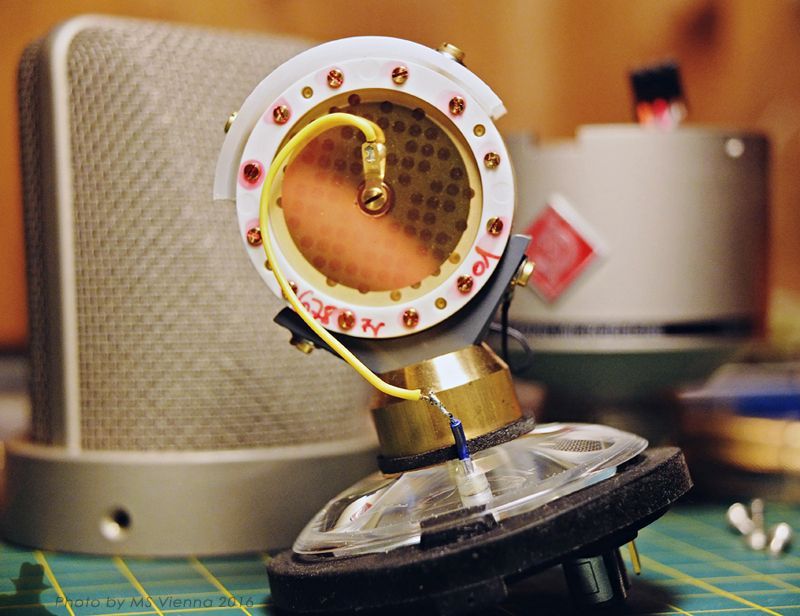

Polished and mounted

I did make a new elastic capsule mount too. Inside the brass part there´s a threaded rubber element like the ones usually used for the purpose. The brass enclosure limits the tilting angle in case the mic receives a physical blow and adds weight (reduces vibration transmission further)

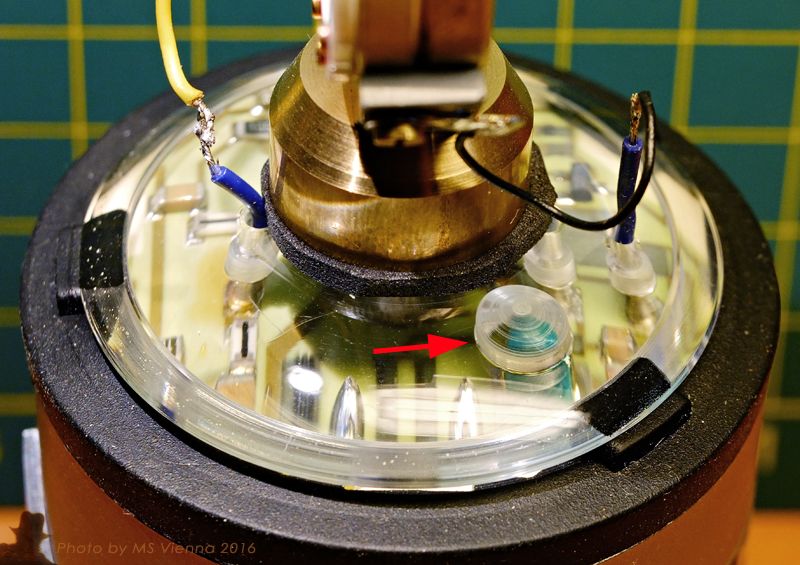

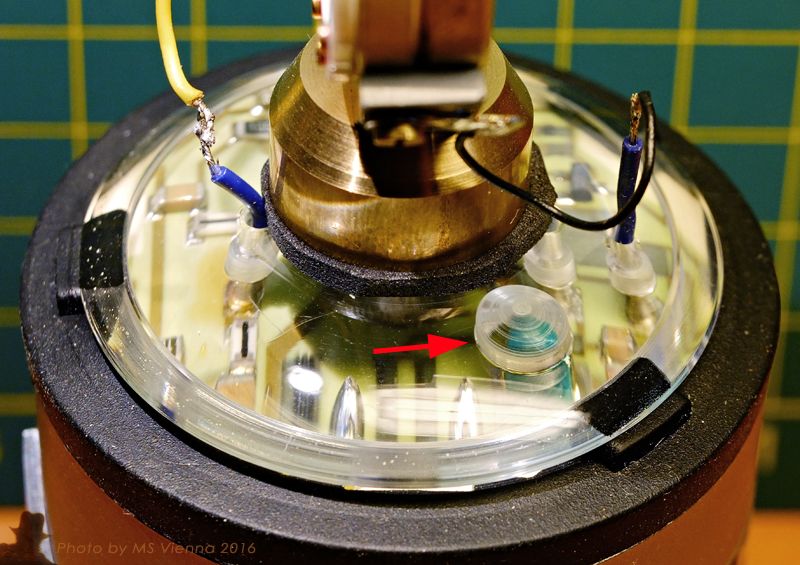

I drilled a hole to accommodate one larger component on the PCB.

This new base assembly shifts the capsule´s position upwards inside the grille to roughly the same position as found in the U87.

And of course the plexi dome starts right below the grille entry - just like in a U67, avoiding any resonance artefacts.

I never felt that my TLM103s´ top end sounded notably harsh (they are relatively early ones from 2001). But there was a certain unevenness thoughout it´s frequency range that I didn´t like - like the midrange being sort of separated from the top end.

The mod certainly helped. The sound is much more homogeneous. It´s like everything just fell in place. The topend is smoother, the (upper) midrange apears to be slightly boosted and the bass slightly less dry/punchy but a bit more on the mellow side.

For my taste definitely an improvement and worth the effort.

the TLM103´s capsule mounting was the first of it´s kind and a bit unusual. Due to the very simple mechanical construction of the mic (obviously to achieve a low selling price) the capsule is directly mounted on the PCB. The PCB is fixed in the mic´s housing by a rubber ring.

Unlike any Neumann LDC mics before the capsule sits quite low in the grille and sees a slightly unfortunate acoustical environment. While the grillecap is a proven design (U67, U87 and similar) the base plane on which the capsule sits (PCB) is way below the lower grille entry, basically creating a shallow cavity.

I think the TLM103 is a great mic for the money with very low noise and good off axis behaviour. Soundwise it leaves some room for improvement. Since nothing can be really done about the capsule or the electronics (by me), I focused on the acoustical shortcomings inside the grille. I had good success with that on my Brauner VM1 so I was encouraged to give it a go on the 103.

If you do a search for U67 capsule assembly pictures you´ll notice that the capsule stands on a polished plastic dome that acts like a diffusor. That´s what I wanted.

After disassembling and with a piece of Plexiglas that´s gonna become the new capsule base.

BTW the original "elastic" capsule mount isn´t elastic at all...

Plexi base before finishing

For tips how to manufacture this please see this posting:

http://groupdiy.com/index.php?topic=63305.msg802223#msg802223

Polished and mounted

I did make a new elastic capsule mount too. Inside the brass part there´s a threaded rubber element like the ones usually used for the purpose. The brass enclosure limits the tilting angle in case the mic receives a physical blow and adds weight (reduces vibration transmission further)

I drilled a hole to accommodate one larger component on the PCB.

This new base assembly shifts the capsule´s position upwards inside the grille to roughly the same position as found in the U87.

And of course the plexi dome starts right below the grille entry - just like in a U67, avoiding any resonance artefacts.

I never felt that my TLM103s´ top end sounded notably harsh (they are relatively early ones from 2001). But there was a certain unevenness thoughout it´s frequency range that I didn´t like - like the midrange being sort of separated from the top end.

The mod certainly helped. The sound is much more homogeneous. It´s like everything just fell in place. The topend is smoother, the (upper) midrange apears to be slightly boosted and the bass slightly less dry/punchy but a bit more on the mellow side.

For my taste definitely an improvement and worth the effort.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)