pucho812

Well-known member

impressive most impressive.

emrr said:Like the fallacy of EL84 combo amps; always an audible vibrating element within the EL84's!

bahrens said:emrr said:Like the fallacy of EL84 combo amps; always an audible vibrating element within the EL84's!

Pretty sweet sounding fallacy with the right circuit/speakers IMO

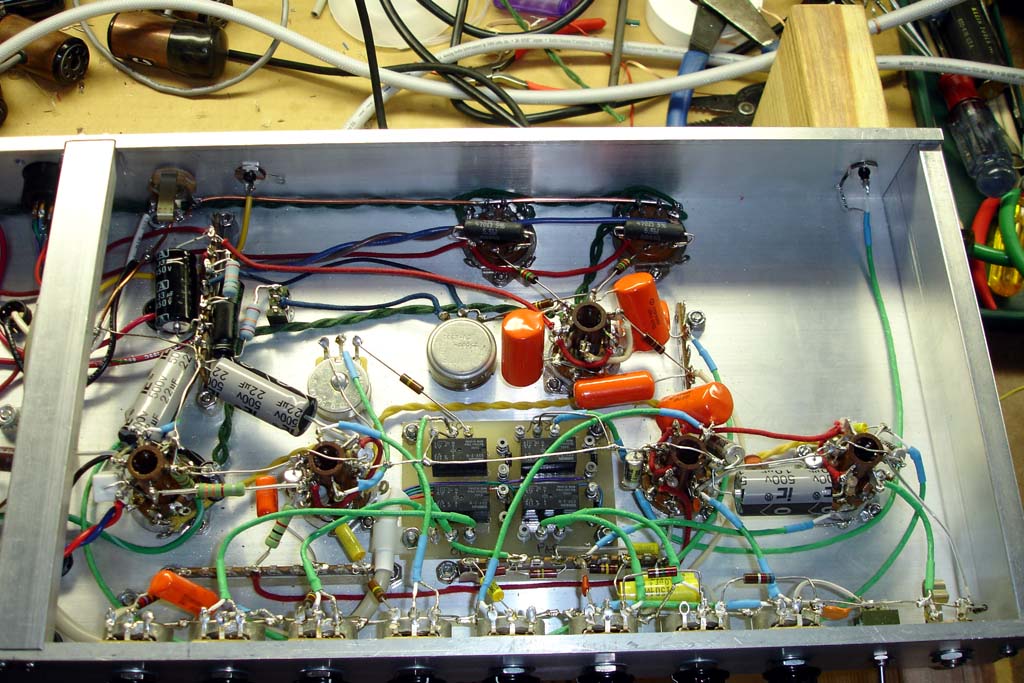

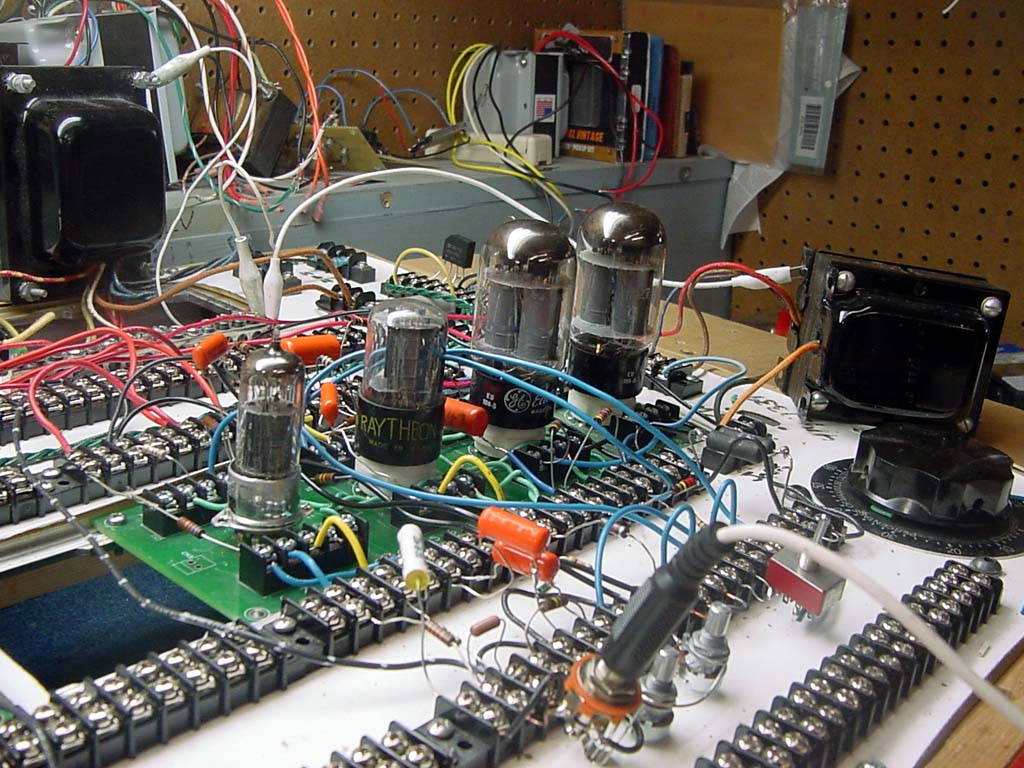

toobdood said:Unsupported solid wire from sockets to controls: This Sh*t WILL break. The layout in old Fenders, Marshalls, et al makes sense from the point of view that wires tucked down against the chassis are UNLIKELY to break or CAUSE breaks like that clean 90 degree layout with LONG UNSUPPORTED LEADS will.

Take this amp and play it and watch the number of those UNSUPPORTED WIRES that will oscillate on a give note. I fix silly sh*t like this for a living.

Butterylicious said:

Enter your email address to join: