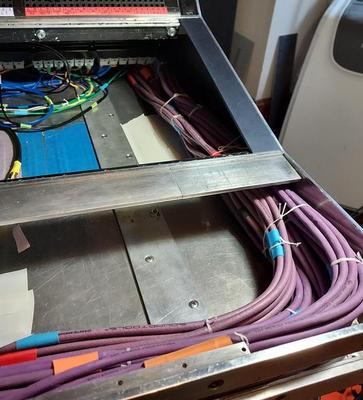

I worked for Harrison for 20 years. This is how the Series10, series 12 and MPC were all connected, using the 3M screened ribbon. (See Brian Roth pictures).

With everything balanced in/out this cabling was never a problem and we had analog consols with over 200 channels (film boards). They were screen/ cold/hot across the ribbon to Harrison pinout (reverse of Tascam), because the mesh shield was pin1 of the ribbon. Have no fear.

With everything balanced in/out this cabling was never a problem and we had analog consols with over 200 channels (film boards). They were screen/ cold/hot across the ribbon to Harrison pinout (reverse of Tascam), because the mesh shield was pin1 of the ribbon. Have no fear.