boji

Well-known member

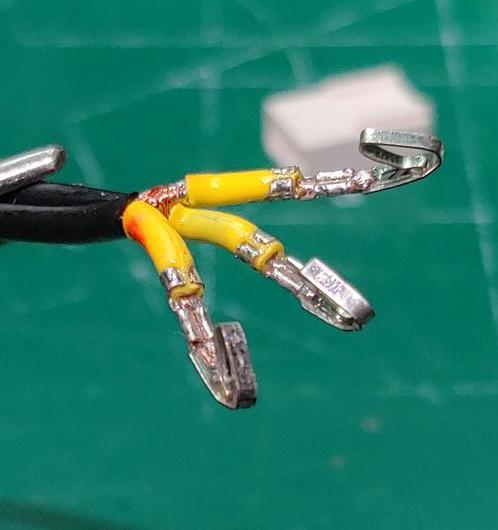

Not sure if people do this, but I tried it out and it gave me great results, so thought I'd share.

Full soak into crimp and wire while avoiding the connector's outside, and left the raised tab dry too. Minimal flux residue.

Full soak into crimp and wire while avoiding the connector's outside, and left the raised tab dry too. Minimal flux residue.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)