skrasms

Well-known member

I did testing of the A/D today. I used the same test circuit as before, reading the voltage directly from the A/D pin.

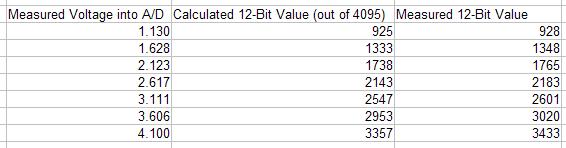

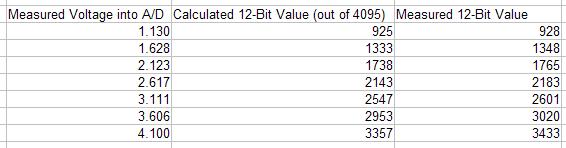

The first column is the voltage read from the A/D pin using my Fluke, and the second column is corresponding digital values calculated from mapping 0-5V to 0-4095. The last column is the data written into the micro from the A/D. What could be causing the nonlinearity in conversion?

For each value tested I watched at least a hundred samples to see how much noise was in the resulting data. Nothing varied by more than a toggling of the least significant bit.

The first column is the voltage read from the A/D pin using my Fluke, and the second column is corresponding digital values calculated from mapping 0-5V to 0-4095. The last column is the data written into the micro from the A/D. What could be causing the nonlinearity in conversion?

For each value tested I watched at least a hundred samples to see how much noise was in the resulting data. Nothing varied by more than a toggling of the least significant bit.