As you probably know, I've been building M7 clones. When my sound isn't quite right, it's usually a clearance issue between the diaphragm and the backplate. I use a capacitance meter to measure my clearance - with the diaphragm the size it is I would expect around 75 pF or so.

You might also try lighter tensioning - I tension my diaphragms using a weight system, but I recall checking the free-air resonance on a few diaphragms and they were in the 800 Hz region from what I recall. On that capsule design, the tension isn't as critical as on other mics (K67, CK12).

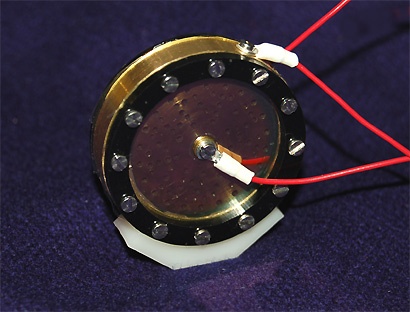

I machine the diaphragm 'spacer' right into the backplate, on all of my mics now, that's the way the M7 was done - it had to be since the diaphragm is glued right onto the backplate. Neumann has switched to this system on their new K47's. I now have a CNC setup on my lathe that makes it easy to get the right clearance. What I used to do was slightly over-cut (I'd do a 40 to 45 micron cut) then lap the edge on 2500-grit abrasive paper on a piece of glass 'till I got the right capacitance on a dummy diaphragm.

That's an awesome job!!! Looks a lot like what I went through a couple years back.

I built a mic using a 6AH6 in exactly the same configuration that you described. It's my main vocal mic now. Sometimes the 6AH6's go a bit noisy though. I usually buy a bunch of tubes and pick the quiet one. EF86 would probably be a better choice.

One thing to watch is that centre screw... is it stainless steel? If so, they don't travel very well when screwed into plastic - especially nylon-based plastics like Delrin. I switched to brass screws and polycarbonate, and the capsules hold together better. The stainless screws don't grab into plastic as well so they'll come undone in shipping.

If you feel like building a lot of them, there's far more demand than I expected for M7/K47 capsules.... but I still find it more fun playing with different hole patterns and trying different things. Sometimes the change you make is good, sometimes it sounds like, well, not good.

I can't say enough encouragement! You've come a long way in a very short time. Awesome!

-Dale