Earlier today I pulled a D12 mic out for a session and it was dead...

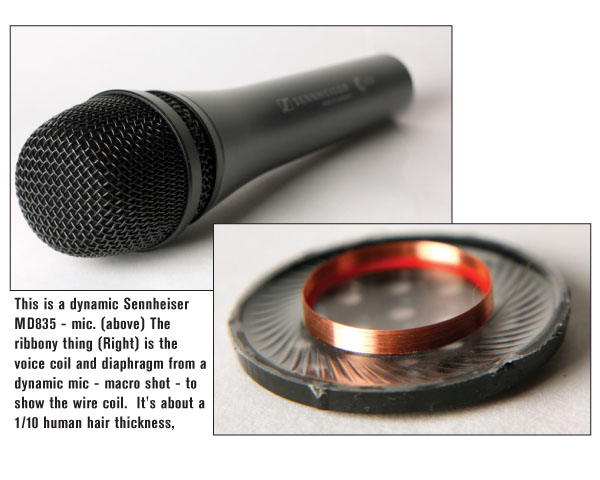

One end of the voice coil has broke.

I was managed to repair the broken voice coil by taking out one turn and solder it to to the output wire.

Now I have another D12 with a broken capsule where the voice coil has completely detached from the diaphragm and can't be repaired.

During the years I saw many old German mics (mostly MD421 / MD21 / D12) with broken capsules that went out of service. So I'm wondering why a replacement diaphragms and voice coils aren't being made no more?

I guess that any manufacture who build dynamic microphones can easily produce those spare parts.

If someone here have any connection to microphones companies please ask them to think about this idea.

One end of the voice coil has broke.

I was managed to repair the broken voice coil by taking out one turn and solder it to to the output wire.

Now I have another D12 with a broken capsule where the voice coil has completely detached from the diaphragm and can't be repaired.

During the years I saw many old German mics (mostly MD421 / MD21 / D12) with broken capsules that went out of service. So I'm wondering why a replacement diaphragms and voice coils aren't being made no more?

I guess that any manufacture who build dynamic microphones can easily produce those spare parts.

If someone here have any connection to microphones companies please ask them to think about this idea.