nielsk

Well-known member

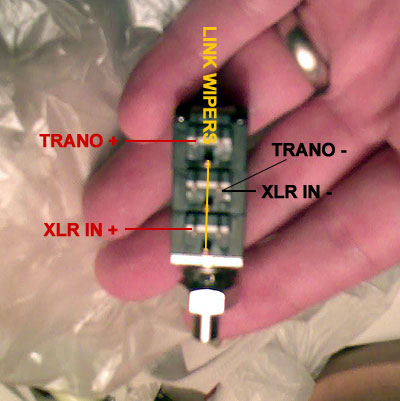

Doooohhhh! finally found the bad solder joint..

all is good, the board works great ( I must add that I am not fond of the black boards, I find being able to shine light through the boards a very useful troubleshooting technique)

the moral of the story is,: check, check and re check. if it is not working, it is your own fault

all is good, the board works great ( I must add that I am not fond of the black boards, I find being able to shine light through the boards a very useful troubleshooting technique)

the moral of the story is,: check, check and re check. if it is not working, it is your own fault