Hey Folks, I'm new here..and i'm still a NOOB so bare with me :-\ it seems like this forum is my last hope to get some answers..

I try to brake the situation down real quick, I want to mod my T-Bone SCT 2000 Microphone, (its exactly the same mic like the Nady TCM1050). I'm not scared to change the Capsule, but I think that i need to change the Output Transformer too..I've also talked to WIMA Caps here in Germany just in case that i need some caps.. but I'll be honest with you guys, i've never hold a soldering iron in my hands..ok I can learn, so I can only hope that you answer some Questions for me. I'm very facinated by the work you guys do and all I wanne do is at least try to mod my mic one time..if i fail..well ,then thats it for my mic .. (at least i managed it to change the Tube allready to a Mullard 12At7U). Anyway here are my Questions.

.. (at least i managed it to change the Tube allready to a Mullard 12At7U). Anyway here are my Questions.

1. Since this Microphone got his own Power supply, I guess the Output Transformer need to be different then on a Phantom powered Condenser mic right?

2. Is there a good Output transformer that you can recommend?

3. Is it true that Tube mics with a PSU need different output transformers then Phantom powered Mics (I worry a lot about all the different voltages going on inside the mic, and that i can "kill" the mic when i hook up a cable wrong, or use the wrong transformer)

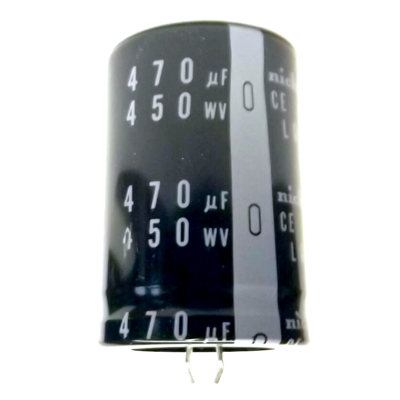

3. How do you know what all the Caps are doing inside the Mic, I mean they all look kinda similar, some are red, some round and blue, and some look like Black "Tubes"..do i need to get a Data sheed about the electricity and all that for the mic to see which cap is doing what? and does it make sense to replace them with WIMA caps?

Sorry..if this was too much for the beginning, but I feel a lilttle lost..Most important to me is to change the Capsule, maybe to a RK-47 Capsule and to change the Output Transformer..

Here are some "Inside pictures" of the Mic..Hope you can help me..Thanks for your time :-[

I try to brake the situation down real quick, I want to mod my T-Bone SCT 2000 Microphone, (its exactly the same mic like the Nady TCM1050). I'm not scared to change the Capsule, but I think that i need to change the Output Transformer too..I've also talked to WIMA Caps here in Germany just in case that i need some caps.. but I'll be honest with you guys, i've never hold a soldering iron in my hands..ok I can learn, so I can only hope that you answer some Questions for me. I'm very facinated by the work you guys do and all I wanne do is at least try to mod my mic one time..if i fail..well ,then thats it for my mic

1. Since this Microphone got his own Power supply, I guess the Output Transformer need to be different then on a Phantom powered Condenser mic right?

2. Is there a good Output transformer that you can recommend?

3. Is it true that Tube mics with a PSU need different output transformers then Phantom powered Mics (I worry a lot about all the different voltages going on inside the mic, and that i can "kill" the mic when i hook up a cable wrong, or use the wrong transformer)

3. How do you know what all the Caps are doing inside the Mic, I mean they all look kinda similar, some are red, some round and blue, and some look like Black "Tubes"..do i need to get a Data sheed about the electricity and all that for the mic to see which cap is doing what? and does it make sense to replace them with WIMA caps?

Sorry..if this was too much for the beginning, but I feel a lilttle lost..Most important to me is to change the Capsule, maybe to a RK-47 Capsule and to change the Output Transformer..

Here are some "Inside pictures" of the Mic..Hope you can help me..Thanks for your time :-[