Hello,

I'm not an electrical engineer and or have a background in electronics, although I am an IT professional by trade. I have taken on an assignment to help contribute to a PC hardware review website who is in need of somebody to review PC power supplies. I began looking into the hardware that would be needed to do the testing and saw the price tags...

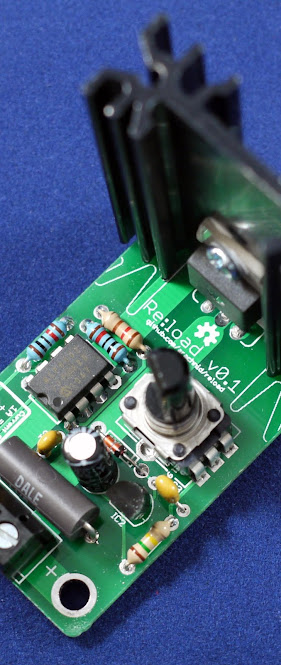

An oscilloscope I don't think I'm going to be able to get away from having to purchase, but while looking around for different options to generate a load to test with, I found the youtube video by dave jones:

https://www.youtube.com/watch?v=8xX2SVcItOA

a little more looking around and I find out everybody and their dog apparently has seen this video and knows about it. I'd like to build something like this but I had a lot of problems to start:

1. I wasn't sure he was speaking english (I'm not refering to his accent)

2. I needed something that could be adjustable from 10% to 100% load of any PC power supply out there

3. it would need to be able to test a single or multiple rails

4. it would have to be able to evenly distribute the load across 3.3v, 5v, and 12v power.

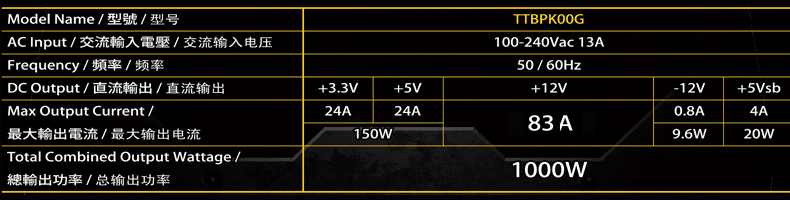

PC power supplies ( I'm sure anybody on here would understand this but I'm trying to be thorough in my explanation) can range anywhere from 250W to 1500W+ giving over 70 amps on a single connection, so this would take a LOT of load which. Dave's load, as he states in the video can only draw 1 or 2 amps.

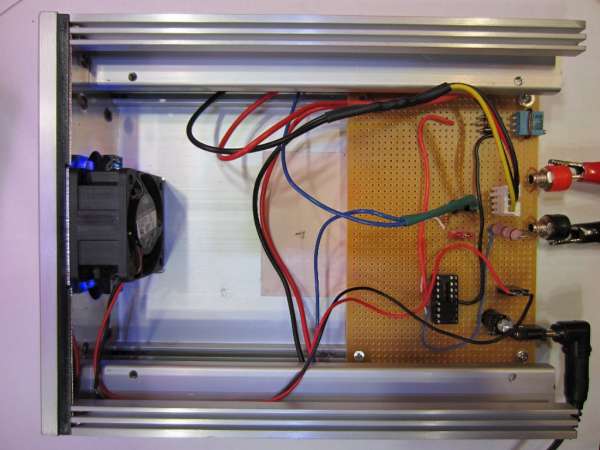

I've been reading up on op-amps and mosfets since those were his two main components and trying to learn how this works so I could try to figure out how to scale up and I had an idea. Instead of trying to make a single load scale up to 1500+W, just scale up, lets say 10 or 20 amp draw and build multiples so that I can adjust each one of them individually. I'm still studying but I got to a point where I needed to try some hands on to better understand. At this point I haven't gotten to building multiples.....I haven't even gotten to building a single one. I'm stuck in a position where I THINK I understand how an op-amp should work, but I'm experimenting and not getting the results I expect. So I'm looking for some help understanding.

I went to radio shack and bought some supplies to start experimenting, here's what I've got on hand:

breadboard w/jumpers

wire

solder

soldering iron

cheap multi-meter (which apparently can't read milli-amps)

1/4 watt variety pack of resisters from 10ohm to 1m ohm

300 degree 100k ohm potentiometer

15 turn 10k potentiometer

8 9V batteries

automotive battery charger (sounds funny I know, but I can get 2A, 10, or 50A at 12V so I thought it might be a good test considering the power I intend to be drawing later and the mosfets I have on hand)

LM741 op-amp

LM324 quad op-am

three 20N60c3 mosfets (I had an old just PC power supply that I decided to cannibalize and found some of these mosfets in it, I looked up their data sheet and they are 600V 20A)

I realize how janky and noob this sounds, but as I mentioned, I'm not an electrical engineer so tools and supplies in this area are not a common part of my repertoire. I need to minimize my expenditure as I am recently unemployed, I don't know when I will be back to work, and this is all in an effort to make extra money to hold me over until I'm employed again.

For the time being, the first problem I'm having is with getting the expected results from an op-amp. I've tried numerous variations to attempt to get some sort of effect but I've had no luck and even what SHOULD be the most simple test is failing

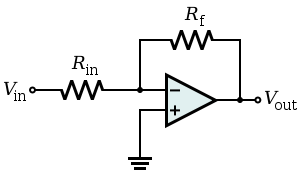

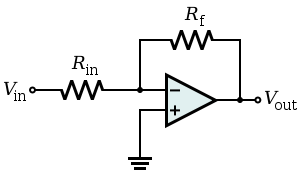

the setup:

V+ connects to positive post of 9V battery

Vout connects to 10 ohm resistor

V- is connected between 10 ohm and 100 ohm resistor

100 ohm connects to negative post of 9v battery

2 9v connected in series, positive post of batt A connects to Vh of op-amp, negative post of batt A to positive post of batt B and negative post of batt B to Vl.

my understanding is this: Vout = Vin(1+(R1/R2)) in this case R1 is 10, R2 is 100 and Vin=9, so I SHOULD see 9.9V but I'm actually getting values in the 8.?? range. I've already been experimenting so my batteries are already not at 100%, and I know there's going to be some amount of V-drop going through the components but I don't know how much I should see or how accurate my reading should be. So in order for a more extreme example so that I should see a large enough result to overcome any loss in voltage I swap the resisters so that R1 is 100 and R2 is 10. When I do the math on that I get 9(1 + (100/10)), 9(1+10), 9(11), = 99 volts. I realize that Vout can't exceed Vh, which should be 18V. when I test this out I get something in the neighborhood of 8V again........ ???

I've been trying to find an answer and so far the only thing I've found that might be related was on this forum. There was a post were somebody was talking about wiring a 9V battery backward and that started me thinking about a V+/V- compared to a V+/ground. I'm still looking for answers but after two weeks of reading I could really use people to ask questions and get advise from. does this "backward battery" issue somehow relate to why I'm not getting the expected outcome? just getting this much answered would be extremely helpful.

I'm not an electrical engineer and or have a background in electronics, although I am an IT professional by trade. I have taken on an assignment to help contribute to a PC hardware review website who is in need of somebody to review PC power supplies. I began looking into the hardware that would be needed to do the testing and saw the price tags...

An oscilloscope I don't think I'm going to be able to get away from having to purchase, but while looking around for different options to generate a load to test with, I found the youtube video by dave jones:

https://www.youtube.com/watch?v=8xX2SVcItOA

a little more looking around and I find out everybody and their dog apparently has seen this video and knows about it. I'd like to build something like this but I had a lot of problems to start:

1. I wasn't sure he was speaking english (I'm not refering to his accent)

2. I needed something that could be adjustable from 10% to 100% load of any PC power supply out there

3. it would need to be able to test a single or multiple rails

4. it would have to be able to evenly distribute the load across 3.3v, 5v, and 12v power.

PC power supplies ( I'm sure anybody on here would understand this but I'm trying to be thorough in my explanation) can range anywhere from 250W to 1500W+ giving over 70 amps on a single connection, so this would take a LOT of load which. Dave's load, as he states in the video can only draw 1 or 2 amps.

I've been reading up on op-amps and mosfets since those were his two main components and trying to learn how this works so I could try to figure out how to scale up and I had an idea. Instead of trying to make a single load scale up to 1500+W, just scale up, lets say 10 or 20 amp draw and build multiples so that I can adjust each one of them individually. I'm still studying but I got to a point where I needed to try some hands on to better understand. At this point I haven't gotten to building multiples.....I haven't even gotten to building a single one. I'm stuck in a position where I THINK I understand how an op-amp should work, but I'm experimenting and not getting the results I expect. So I'm looking for some help understanding.

I went to radio shack and bought some supplies to start experimenting, here's what I've got on hand:

breadboard w/jumpers

wire

solder

soldering iron

cheap multi-meter (which apparently can't read milli-amps)

1/4 watt variety pack of resisters from 10ohm to 1m ohm

300 degree 100k ohm potentiometer

15 turn 10k potentiometer

8 9V batteries

automotive battery charger (sounds funny I know, but I can get 2A, 10, or 50A at 12V so I thought it might be a good test considering the power I intend to be drawing later and the mosfets I have on hand)

LM741 op-amp

LM324 quad op-am

three 20N60c3 mosfets (I had an old just PC power supply that I decided to cannibalize and found some of these mosfets in it, I looked up their data sheet and they are 600V 20A)

I realize how janky and noob this sounds, but as I mentioned, I'm not an electrical engineer so tools and supplies in this area are not a common part of my repertoire. I need to minimize my expenditure as I am recently unemployed, I don't know when I will be back to work, and this is all in an effort to make extra money to hold me over until I'm employed again.

For the time being, the first problem I'm having is with getting the expected results from an op-amp. I've tried numerous variations to attempt to get some sort of effect but I've had no luck and even what SHOULD be the most simple test is failing

the setup:

V+ connects to positive post of 9V battery

Vout connects to 10 ohm resistor

V- is connected between 10 ohm and 100 ohm resistor

100 ohm connects to negative post of 9v battery

2 9v connected in series, positive post of batt A connects to Vh of op-amp, negative post of batt A to positive post of batt B and negative post of batt B to Vl.

my understanding is this: Vout = Vin(1+(R1/R2)) in this case R1 is 10, R2 is 100 and Vin=9, so I SHOULD see 9.9V but I'm actually getting values in the 8.?? range. I've already been experimenting so my batteries are already not at 100%, and I know there's going to be some amount of V-drop going through the components but I don't know how much I should see or how accurate my reading should be. So in order for a more extreme example so that I should see a large enough result to overcome any loss in voltage I swap the resisters so that R1 is 100 and R2 is 10. When I do the math on that I get 9(1 + (100/10)), 9(1+10), 9(11), = 99 volts. I realize that Vout can't exceed Vh, which should be 18V. when I test this out I get something in the neighborhood of 8V again........ ???

I've been trying to find an answer and so far the only thing I've found that might be related was on this forum. There was a post were somebody was talking about wiring a 9V battery backward and that started me thinking about a V+/V- compared to a V+/ground. I'm still looking for answers but after two weeks of reading I could really use people to ask questions and get advise from. does this "backward battery" issue somehow relate to why I'm not getting the expected outcome? just getting this much answered would be extremely helpful.