You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D-LA2A Support Thread

- Thread starter [silent:arts]

- Start date

Help Support GroupDIY Audio Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Assuming this thread isn't dead yet

I've seen it mentioned in the transformer meta, that an UTC a16 could be used for a la2a input. I see it has a very different impedance ratio as opposed to the a10. What I find asking myself is how would one wire these as la2a inputs? Do we need to change anything onboard to accomodate the UTCs?

Thanks,

B.

I've seen it mentioned in the transformer meta, that an UTC a16 could be used for a la2a input. I see it has a very different impedance ratio as opposed to the a10. What I find asking myself is how would one wire these as la2a inputs? Do we need to change anything onboard to accomodate the UTCs?

Thanks,

B.

azone

Active member

- Joined

- Jul 8, 2010

- Messages

- 32

I'm getting started on a build and I have a few simple questions.

1. I'm looking to use Hairball VU meters. I see there are (3) kinds on the website. They seem to be spec'd pretty much the same with the exception of some mechanical differences and LED versus lamps etc... I'm going to be building mine into a 2U case. Is there an advantage of any of the meters over the others other than looks? Will the lamps in the 3rd version run bright enough with the stock supply voltage?

The choices are

a) 8027-B VU Meter

b) 027-WF VU Meter

c) Custom Hairball Audio FET Compressor VU Meter

http://hairballaudio.com/shop/index.php?cPath=25

2. I'd like to use a torroidal power transformer. I've seen a couple people using them. Where are you getting them? I assume they are custom wound because of the multiple/non-standard windings?

3. I'm putting together a US BOM as I go. There was a link but it doesn't work. Does anybody know the manufacturer/part # for all the connectors, I haven't found anything in my searches. I'd be happy to cross-reference to other manufacturers/Mouser part#'s if I could get the specs.

Cheers, Brian.

1. I'm looking to use Hairball VU meters. I see there are (3) kinds on the website. They seem to be spec'd pretty much the same with the exception of some mechanical differences and LED versus lamps etc... I'm going to be building mine into a 2U case. Is there an advantage of any of the meters over the others other than looks? Will the lamps in the 3rd version run bright enough with the stock supply voltage?

The choices are

a) 8027-B VU Meter

b) 027-WF VU Meter

c) Custom Hairball Audio FET Compressor VU Meter

http://hairballaudio.com/shop/index.php?cPath=25

2. I'd like to use a torroidal power transformer. I've seen a couple people using them. Where are you getting them? I assume they are custom wound because of the multiple/non-standard windings?

3. I'm putting together a US BOM as I go. There was a link but it doesn't work. Does anybody know the manufacturer/part # for all the connectors, I haven't found anything in my searches. I'd be happy to cross-reference to other manufacturers/Mouser part#'s if I could get the specs.

Cheers, Brian.

Silvas

Well-known member

I used an Antek 1T250 for the heaters and HT. Had to use a second small toroid for the other PSU, but i think you can use a 12v one, and a 7812 regulator and 12v relays, so you can run the VU lamps.

azone

Active member

- Joined

- Jul 8, 2010

- Messages

- 32

got it. thanks.I used an Antek 1T250 for the heaters and HT. Had to use a second small toroid for the other PSU, but i think you can use a 12v one, and a 7812 regulator and 12v relays, so you can run the VU lamps

azone

Active member

- Joined

- Jul 8, 2010

- Messages

- 32

I have a couple more questions

1. Tube sockets. I've read through all the threads here an the one on nrgrecording forum and I can't figure out what tube sockets are required. I'm stuffing it into a 2U rack so it may be important choice for the lowest profile. Anyone got any idea on part #'s? I tried to figure it out from the german BOM but no luck.

2. Is a socket needed for the T4B?

1. Tube sockets. I've read through all the threads here an the one on nrgrecording forum and I can't figure out what tube sockets are required. I'm stuffing it into a 2U rack so it may be important choice for the lowest profile. Anyone got any idea on part #'s? I tried to figure it out from the german BOM but no luck.

2. Is a socket needed for the T4B?

$15.98

$16.98

Gikfun Upgraded USB Mini Amplifier Electronic Transparent Stereo Speaker Box Sound Amplifier DIY Kit for Arduino EK1918

Gikfun_Official_Store

azone

Active member

- Joined

- Jul 8, 2010

- Messages

- 32

--------------------------------------------------------------------------------------------------------------------------------------------------

August 11 2010 [Note: I rearranged this thread for oldest-post-first, makes more sense to newcomers]

I'm going to start a mini-blog of my build here. I think maybe it will some other people who are trying to get all the pieces together and get one built. Especially for the guys in the US I will be putting together a BOM.

Aside from this forum thread I found most of the parts list by cross referencing the PCB layout with the LA2A schematic and the Drip Audio BOM. The most difficult part is double checking the PCB footprints of all parts so that they fit silent:arts PCB. I will be adding notes in detail as I go along.

Things I haven't ordered yet

1. Power transformer [undecided]

2. 0.1uF polypropylene caps

3. 12BH7A & 6AQ5A tubes [undecided]

Things that haven't arrived yet

1. (2) 24-position switches [diypartssupply.com / part #Elma 24 position rotary]

2. 2U Enclosure [par-metal.com / part #10-19113B]

3. (2) input transformer [edcorsa.com / part #WSM600/15k]

4. (2) output transformer [edcorusa.com / part #WSM15k/600]

5. (4) Arco 46-series Trimmer Capacitor [surplussales.com / part #(CTM)465]

Parts on-hand

1. T4B [acquired pair of NOS for decent price]

2. Resistors, caps, connectors, relays [most already on-hand, rest from Mouser, BOM to come]

3. (2) 100k potentiometers [Digikey]

4. Tube sockets [tubedepot.com]

5. (2) VU meters [hairballaudio.com / part #HB-8037]

Things I still need to complete the main PCB

1. 0.1uF polypropylene caps. I still need four. I have various mallory, vishay etc.., but most are >20mm long and don't fit the footprint which is meant for a Solen.

2. Install sockets for the 6AQ5A's. I am going to have to trim the leads on these. I'm going to wait until the enclosure arrives to determine exactly how much I need to.

3. Install heater wires. I will do this last, before the last time I clean the PCB.

Thanks everyone for sharing all the knowledge here on the forums, I've been able to pick around and find most of what I need. Also thanks to crisotop for answering my PM's regarding some specific details.

As probably everyone who has completed one of these already knows the hard part of this clone is not actually building it, it's ordering all the correct parts, options, etc.. and managing the build!

As I mentioned above I will be uploading a US BOM shortly as I get all the info together. click on images for link to large versions

--------------------------------------------------------------------------------------------------------------------------------------------------

August 12 2010

A few notes on stuffing the PCB.

1. I used 1/2W resistors throughout (except where 3W required). The board was laid out for 1/4W so it can be a tight fit in some cases. I used 1/2W because I had them and the original used them, although I didn't simulate the circuit or anything so it's very likely 1/4W is ok as has been used by many. Just be careful if using 1/2W it'll be tight, see pics below.

2. The PCB footprint for the 3W resistors is short for most 3W resistors you will find. No problem, you'll just need to stand them up on one end as you can see below (and in many other peoples builds).

3. About the front panel I'm having one made by front panel express. I'll share it when I'm done.

--------------------------------------------------------------------------------------------------------------------------------------------------

August 13 2010

I ordered the power transformer(s) today. I'm using two to avoid having to have a custom made.

1. Antek AN-IT250, 100VA, 250V @ 0.20A + 6.3V @ 3A. This will power the main circuit and the heaters.

2. Antek AN-0012, 5VA, 12V @ 0.20A. This will power the relays (12V version) and the VU meter lamps which are also 12V.

I also finally ordered the 0.1uF Solen caps while placing another order from tubedepot.com, as well as some of those nice antique style knobs they have.

I also bought some NOS RCA tubes for the 12BH7A and 6AQ5's.

--------------------------------------------------------------------------------------------------------------------------------------------------

August 21 2010

1. power transformers came in. Not crazy about the big 100VA torroid, way overkill for the application, might try to find one lying around at work that'll give me more space and help me keep it out of the way from the PCB.

2. audio transformers are due early next week, they are the Edcor 2x WSM600/15k, 2x WSM15k/600.

3. Elma 24 position rotary's are also due next week. I decided to use them for all four controls.

4. last of the caps and other remaining parts came this week.

5. Par-metal enclosure came this week, www.par-metal.com, part #10-19113x, price is good and has vents.

I was able to test the height of the setup in the 2U enclosure. Even with generous 1/4" standoff's I still have a good 1/4" space at the top of the enclosure. The Par-metal enclosure is a six-sided type, and typically gives the most height from top & bottom since the top & bottom panels screw over the end panels so there is no wasted height. I have not tested whether the top panel can deflect enough to touch the T4B's and the 12BH7's (they are at about exactly the same height). I trimmed both sides of each lead on the 6AQ5 sockets as shown in the picture below but I didn't trim the leads for the 12BH7's. The second picture below shows the clearance looking from the front of the enclosure (click for larger image).

I also soldered the heater wires. One of the 6AQ5 sockets is not soldered in yet so you can see there's a few wires not connected there yet.

--------------------------------------------------------------------------------------------------------------------------------------------------

August 27 2010

1. Still waiting for a lot of parts to come in. No problem though, still a lot to do.

2. A few changes have come up. I want to make a point to point out any changes or troubles that come about. It's not all as easy at it can look sometimes. The toroid power transformer from Antek was huge, 100VA huge, and I didn't want to deal with it and have to have the smaller toroid in there as well. It would be an unnecessary pain. It occurred to me that Volker may have some custom Toroids still, and he does! so I ordered one. The price is very fair for a custom wind that's perfect for the application. Also, I ordered another enclosure. I found the Par-Metal 10-19113 was a little short at 11" depth, making things tight. I purchased the next larger model, part# 10-19143. It's 14" deep. I was very happy with the quality of the par-metal part, and the service I've been getting from the Par-Metal/Antek guys has been good. Now I'll have to do another project with the original case

3. Here's what the Edcor transformers look like. Yeah I know, boring, but size, shape, layout may help someone out who's planning a D-LA2A in the future. (click for larger image)

4. I'm working on the first-pass front panel. Here's what the rough 1:1 layout looks like right now. I'm going to implement an active wet/dry mix control so that's what the middle knob is for.

Those big knobs are from Eagle plastics, I bought them at Mouser, part# 45KN014-GRX.

The smaller knob and pilot light is from www.tubedepot.com part#'s P-SAK, P-PL-JEWEL, & P-PL-FENDER-STYLE

--------------------------------------------------------------------------------------------------------------------------------------------------

September 1 2010

1. VU Meter LED retrofit

At the time I bought the meters from www.hairballaudio.com they were only available with 12V lamp. Since the D-LA2A has an auxiliary 5V supply for the meter back-lighting and mechanical relays it makes more sense to go with something powered by 5V. Using LED's seemed the best bet since you can get any color variation and you'll never have to worry about replacing lamps. I emailed Mike @ Hairball to inquire about how the manufacturer retrofits LED's into the meters. The ones they sell have two LED's wired in series as shown below:

Since the D-LA2A supplies 5V to the meter back-light (fairly low voltage) you may want wire the LED's in parallel so they can reach desired brightness. Since most LED's have ~2V forward voltage, two in series would be ~4V and the brightness would not be enough even with no series resistor. Basically, either wire two typical LED's in parallel and calculate the appropriate series resistor, or use specific 5V LED's with low reverse breakdown voltage with an appropriate series resistor and they will work. I used two 5mm clear amber LED's for each lamp housing and it worked very well, the brightness is uniform over the whole meter. For best uniform coverage of the VU meter it's best to use clear LED's (not diffuse) and to angle them at 90 degrees towards the back of the VU Meter as you can see in the pics:

2. Elma 24-position switches [edited]

I installed the resistors to the Elma switches. Two of them are set for 100k log and two for 33k log (to be used in series with 68K resistor for less gain).

If you haven't used switches like this before where you add your own resistors etc.. it can be confusing.

a) Look at it as a potentiometer, a voltage divider, since this is what it is anyway, a stepped attenuator. Check out this Elma schematic from the Goldpoint Level controls website http://www.goldpt.com/schm_ser.html

b) Realize that the end-stop is before position 0, and the first resistor R1 should go at position 0.

c) The marking on the Elma part shows 0 to 22. These marking fall between switch positions and can be thought of as resistor numbers. There will be (23) resistors total when completely fitted.

d) Use silent:arts log-pot-to-switch excel document to calculate the resistor values.. http://www.silentarts.de/DIY/PM660/LogPotToSwitch.xls

--------------------------------------------------------------------------------------------------------------------------------------------------

September 12 2010

Just a quick update, no pictures.

1. I've got everything hooked up and have done some quick tests. everything is working.

2. I will be adding some details and pictures soon.

3. currently I am using a temporary front panel and the Edcor transformers.

4. I am sending out to have a custom panel made. It will be a good 3-4 weeks before it comes back.

5. I got a hold of a UTC HA-100x, A-24, and A-25. All were in a cinema preamp & effects switcher I found while scouring Ebay. I picked up the whole thing for relatively cheap, I'll most likely sell the A-25 and compare the original HA-100/A-24 versus the Edcors. When the time comes I'll take a bunch of audio samples and measurements on my Audio Precision system to compare them.

6. I'm almost complete with a very detailed US BOM. I'll upload it and to link to it very soon.

--------------------------------------------------------------------------------------------------------------------------------------------------

September 14 2010

I posted the US BOM further down in this thread but here it is again...

D-LA2A US BOM (XLS)

D-LA2A US BOM (PDF)

--------------------------------------------------------------------------------------------------------------------------------------------------

September 26 2010

Just a quick update. no new news yet, still a lot of updates, finished details to update soon.

August 11 2010 [Note: I rearranged this thread for oldest-post-first, makes more sense to newcomers]

I'm going to start a mini-blog of my build here. I think maybe it will some other people who are trying to get all the pieces together and get one built. Especially for the guys in the US I will be putting together a BOM.

Aside from this forum thread I found most of the parts list by cross referencing the PCB layout with the LA2A schematic and the Drip Audio BOM. The most difficult part is double checking the PCB footprints of all parts so that they fit silent:arts PCB. I will be adding notes in detail as I go along.

Things I haven't ordered yet

1. Power transformer [undecided]

2. 0.1uF polypropylene caps

3. 12BH7A & 6AQ5A tubes [undecided]

Things that haven't arrived yet

1. (2) 24-position switches [diypartssupply.com / part #Elma 24 position rotary]

2. 2U Enclosure [par-metal.com / part #10-19113B]

3. (2) input transformer [edcorsa.com / part #WSM600/15k]

4. (2) output transformer [edcorusa.com / part #WSM15k/600]

5. (4) Arco 46-series Trimmer Capacitor [surplussales.com / part #(CTM)465]

Parts on-hand

1. T4B [acquired pair of NOS for decent price]

2. Resistors, caps, connectors, relays [most already on-hand, rest from Mouser, BOM to come]

3. (2) 100k potentiometers [Digikey]

4. Tube sockets [tubedepot.com]

5. (2) VU meters [hairballaudio.com / part #HB-8037]

Things I still need to complete the main PCB

1. 0.1uF polypropylene caps. I still need four. I have various mallory, vishay etc.., but most are >20mm long and don't fit the footprint which is meant for a Solen.

2. Install sockets for the 6AQ5A's. I am going to have to trim the leads on these. I'm going to wait until the enclosure arrives to determine exactly how much I need to.

3. Install heater wires. I will do this last, before the last time I clean the PCB.

Thanks everyone for sharing all the knowledge here on the forums, I've been able to pick around and find most of what I need. Also thanks to crisotop for answering my PM's regarding some specific details.

As probably everyone who has completed one of these already knows the hard part of this clone is not actually building it, it's ordering all the correct parts, options, etc.. and managing the build!

As I mentioned above I will be uploading a US BOM shortly as I get all the info together. click on images for link to large versions

--------------------------------------------------------------------------------------------------------------------------------------------------

August 12 2010

A few notes on stuffing the PCB.

1. I used 1/2W resistors throughout (except where 3W required). The board was laid out for 1/4W so it can be a tight fit in some cases. I used 1/2W because I had them and the original used them, although I didn't simulate the circuit or anything so it's very likely 1/4W is ok as has been used by many. Just be careful if using 1/2W it'll be tight, see pics below.

2. The PCB footprint for the 3W resistors is short for most 3W resistors you will find. No problem, you'll just need to stand them up on one end as you can see below (and in many other peoples builds).

3. About the front panel I'm having one made by front panel express. I'll share it when I'm done.

--------------------------------------------------------------------------------------------------------------------------------------------------

August 13 2010

I ordered the power transformer(s) today. I'm using two to avoid having to have a custom made.

1. Antek AN-IT250, 100VA, 250V @ 0.20A + 6.3V @ 3A. This will power the main circuit and the heaters.

2. Antek AN-0012, 5VA, 12V @ 0.20A. This will power the relays (12V version) and the VU meter lamps which are also 12V.

I also finally ordered the 0.1uF Solen caps while placing another order from tubedepot.com, as well as some of those nice antique style knobs they have.

I also bought some NOS RCA tubes for the 12BH7A and 6AQ5's.

--------------------------------------------------------------------------------------------------------------------------------------------------

August 21 2010

1. power transformers came in. Not crazy about the big 100VA torroid, way overkill for the application, might try to find one lying around at work that'll give me more space and help me keep it out of the way from the PCB.

2. audio transformers are due early next week, they are the Edcor 2x WSM600/15k, 2x WSM15k/600.

3. Elma 24 position rotary's are also due next week. I decided to use them for all four controls.

4. last of the caps and other remaining parts came this week.

5. Par-metal enclosure came this week, www.par-metal.com, part #10-19113x, price is good and has vents.

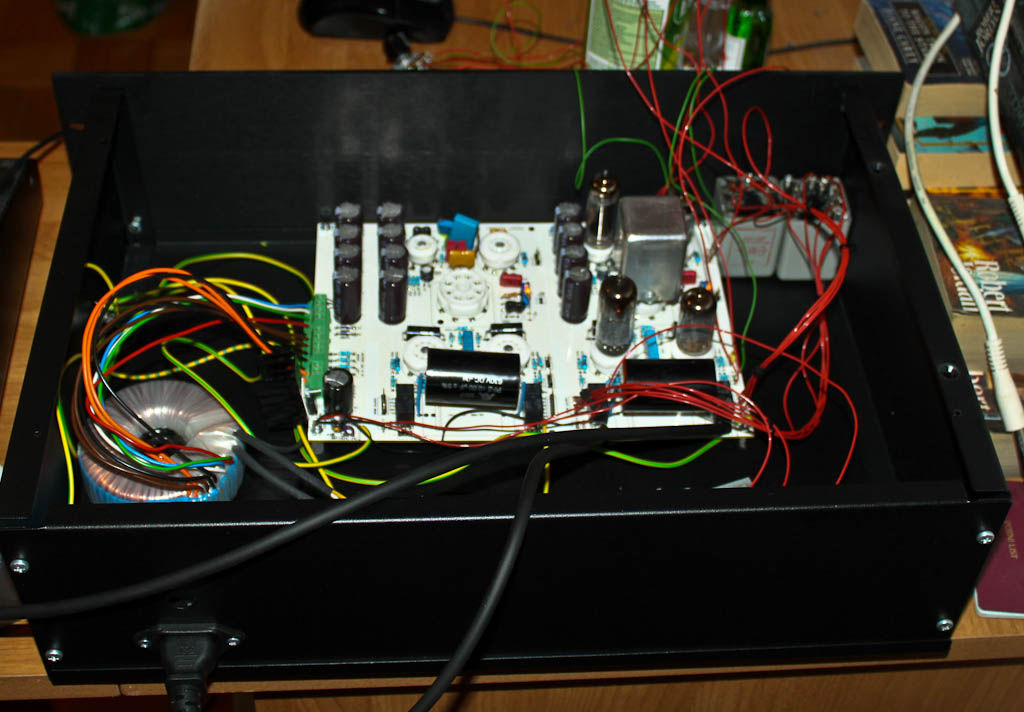

I was able to test the height of the setup in the 2U enclosure. Even with generous 1/4" standoff's I still have a good 1/4" space at the top of the enclosure. The Par-metal enclosure is a six-sided type, and typically gives the most height from top & bottom since the top & bottom panels screw over the end panels so there is no wasted height. I have not tested whether the top panel can deflect enough to touch the T4B's and the 12BH7's (they are at about exactly the same height). I trimmed both sides of each lead on the 6AQ5 sockets as shown in the picture below but I didn't trim the leads for the 12BH7's. The second picture below shows the clearance looking from the front of the enclosure (click for larger image).

I also soldered the heater wires. One of the 6AQ5 sockets is not soldered in yet so you can see there's a few wires not connected there yet.

--------------------------------------------------------------------------------------------------------------------------------------------------

August 27 2010

1. Still waiting for a lot of parts to come in. No problem though, still a lot to do.

2. A few changes have come up. I want to make a point to point out any changes or troubles that come about. It's not all as easy at it can look sometimes. The toroid power transformer from Antek was huge, 100VA huge, and I didn't want to deal with it and have to have the smaller toroid in there as well. It would be an unnecessary pain. It occurred to me that Volker may have some custom Toroids still, and he does! so I ordered one. The price is very fair for a custom wind that's perfect for the application. Also, I ordered another enclosure. I found the Par-Metal 10-19113 was a little short at 11" depth, making things tight. I purchased the next larger model, part# 10-19143. It's 14" deep. I was very happy with the quality of the par-metal part, and the service I've been getting from the Par-Metal/Antek guys has been good. Now I'll have to do another project with the original case

3. Here's what the Edcor transformers look like. Yeah I know, boring, but size, shape, layout may help someone out who's planning a D-LA2A in the future. (click for larger image)

4. I'm working on the first-pass front panel. Here's what the rough 1:1 layout looks like right now. I'm going to implement an active wet/dry mix control so that's what the middle knob is for.

Those big knobs are from Eagle plastics, I bought them at Mouser, part# 45KN014-GRX.

The smaller knob and pilot light is from www.tubedepot.com part#'s P-SAK, P-PL-JEWEL, & P-PL-FENDER-STYLE

--------------------------------------------------------------------------------------------------------------------------------------------------

September 1 2010

1. VU Meter LED retrofit

At the time I bought the meters from www.hairballaudio.com they were only available with 12V lamp. Since the D-LA2A has an auxiliary 5V supply for the meter back-lighting and mechanical relays it makes more sense to go with something powered by 5V. Using LED's seemed the best bet since you can get any color variation and you'll never have to worry about replacing lamps. I emailed Mike @ Hairball to inquire about how the manufacturer retrofits LED's into the meters. The ones they sell have two LED's wired in series as shown below:

Since the D-LA2A supplies 5V to the meter back-light (fairly low voltage) you may want wire the LED's in parallel so they can reach desired brightness. Since most LED's have ~2V forward voltage, two in series would be ~4V and the brightness would not be enough even with no series resistor. Basically, either wire two typical LED's in parallel and calculate the appropriate series resistor, or use specific 5V LED's with low reverse breakdown voltage with an appropriate series resistor and they will work. I used two 5mm clear amber LED's for each lamp housing and it worked very well, the brightness is uniform over the whole meter. For best uniform coverage of the VU meter it's best to use clear LED's (not diffuse) and to angle them at 90 degrees towards the back of the VU Meter as you can see in the pics:

2. Elma 24-position switches [edited]

I installed the resistors to the Elma switches. Two of them are set for 100k log and two for 33k log (to be used in series with 68K resistor for less gain).

If you haven't used switches like this before where you add your own resistors etc.. it can be confusing.

a) Look at it as a potentiometer, a voltage divider, since this is what it is anyway, a stepped attenuator. Check out this Elma schematic from the Goldpoint Level controls website http://www.goldpt.com/schm_ser.html

b) Realize that the end-stop is before position 0, and the first resistor R1 should go at position 0.

c) The marking on the Elma part shows 0 to 22. These marking fall between switch positions and can be thought of as resistor numbers. There will be (23) resistors total when completely fitted.

d) Use silent:arts log-pot-to-switch excel document to calculate the resistor values.. http://www.silentarts.de/DIY/PM660/LogPotToSwitch.xls

--------------------------------------------------------------------------------------------------------------------------------------------------

September 12 2010

Just a quick update, no pictures.

1. I've got everything hooked up and have done some quick tests. everything is working.

2. I will be adding some details and pictures soon.

3. currently I am using a temporary front panel and the Edcor transformers.

4. I am sending out to have a custom panel made. It will be a good 3-4 weeks before it comes back.

5. I got a hold of a UTC HA-100x, A-24, and A-25. All were in a cinema preamp & effects switcher I found while scouring Ebay. I picked up the whole thing for relatively cheap, I'll most likely sell the A-25 and compare the original HA-100/A-24 versus the Edcors. When the time comes I'll take a bunch of audio samples and measurements on my Audio Precision system to compare them.

6. I'm almost complete with a very detailed US BOM. I'll upload it and to link to it very soon.

--------------------------------------------------------------------------------------------------------------------------------------------------

September 14 2010

I posted the US BOM further down in this thread but here it is again...

D-LA2A US BOM (XLS)

D-LA2A US BOM (PDF)

--------------------------------------------------------------------------------------------------------------------------------------------------

September 26 2010

Just a quick update. no new news yet, still a lot of updates, finished details to update soon.

rob_gould

Well-known member

Good work. I really need to get cracking with this too. I have case, transformers, meters and PCB fully stuffed too so there are no excuses really.

Looking forward to see how your build progresses. What are your plans for a front panel?

Looking forward to see how your build progresses. What are your plans for a front panel?

I have obtained the custom power transformer for dla2a quite some time ago..

Connecting it like this:

yellow -> 220v (mains)

white -> link to other yellow

other white -> 220v (mains)

I get 0.2V AC on the 250V taps and ~0.04V AC on others. Is the transformer dead? Or have I just miswired it?

Cheers,

B.

Connecting it like this:

yellow -> 220v (mains)

white -> link to other yellow

other white -> 220v (mains)

I get 0.2V AC on the 250V taps and ~0.04V AC on others. Is the transformer dead? Or have I just miswired it?

Cheers,

B.

stereokillah

Well-known member

is your transformer conected to the board? if yes try disconected, if not your wiring seems to be fine check a new time.

Ugh! Cold solder joint on the voltage switcher.. didn't actually connect the two sides together, oops. Works now, I get proper voltages on the terminals. When connected for the first time, I heard a faint pop, but the neeons and first row of tubes have lit up. The other row has shields, so I didn't see with all the reflections if they really lit up and i'll check that in the dark today.

Incidentally, how do you bypass this unit (I have the white PCBs)? There seem to be relays on board, what are they switched with? I found no bypass switch pads.. do you switch the 5V to the relays?

Cheers,

B.

Incidentally, how do you bypass this unit (I have the white PCBs)? There seem to be relays on board, what are they switched with? I found no bypass switch pads.. do you switch the 5V to the relays?

Cheers,

B.

stereokillah

Well-known member

should be help you

stereokillah said:should be help you

Thanks! yes, it's clear now..

I'm wiring UTC A-16 as inputs and A-24 as output (I have only one though).

The A-16 is a 15k : 60k transformer, with P and B pins on the primary and 60k G and F pins on the secondary and a pin that has the ground symbol. That said, how should I wire it in a DLA2A?

- P to Brown

- B to Green

- G to Blue

- F to Grey

- Ground to Black

The A-24 is more complex, with pins numbered 1 through 10 and a ground symbol pin. It's primary is 15k on pins 7 and 10, when pins 8 and 9 are joined. The join has a "CT" annotation with it.

For 500Ohm secondary operation (probably what I want, right) the pins 1 and 6 carry the signal when 3 and 4 are joined. This join has "CT" as well. So this gets a bit more tricky for me..

- join 8 and 9

- yellow to 7

- green to 10

- join 3 and 4

- grey to 1

- pink to 6

- black to ground

This is a bit confusing... thanks in advance to someone who can help!

Also, since I have no output transformer yet for one channel, can I just not run that channel by not having tubes and t4b populated in that half?

Cheers,

B.

The A-16 is a 15k : 60k transformer, with P and B pins on the primary and 60k G and F pins on the secondary and a pin that has the ground symbol. That said, how should I wire it in a DLA2A?

- P to Brown

- B to Green

- G to Blue

- F to Grey

- Ground to Black

The A-24 is more complex, with pins numbered 1 through 10 and a ground symbol pin. It's primary is 15k on pins 7 and 10, when pins 8 and 9 are joined. The join has a "CT" annotation with it.

For 500Ohm secondary operation (probably what I want, right) the pins 1 and 6 carry the signal when 3 and 4 are joined. This join has "CT" as well. So this gets a bit more tricky for me..

- join 8 and 9

- yellow to 7

- green to 10

- join 3 and 4

- grey to 1

- pink to 6

- black to ground

This is a bit confusing... thanks in advance to someone who can help!

Also, since I have no output transformer yet for one channel, can I just not run that channel by not having tubes and t4b populated in that half?

Cheers,

B.

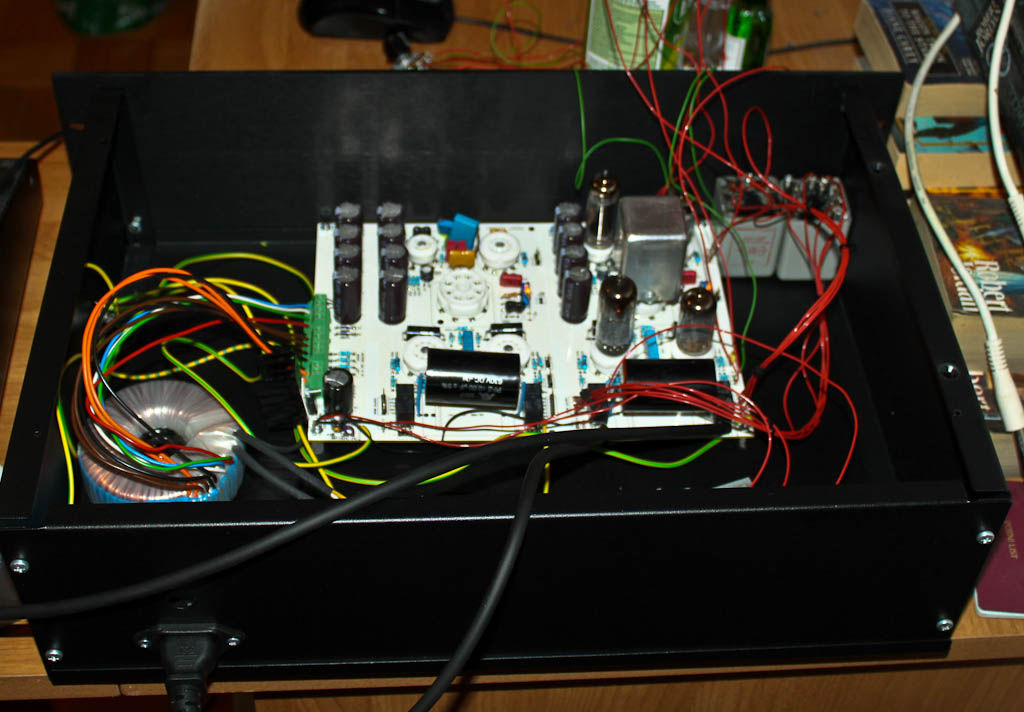

It works... now I need one more A-24, cut the front and back panels and shield the audio cables that I didn't care to for this "wiring" experiment.

The photos:

EDIT: this things rocks on vocals and bass and guitars ... but you know that already

The photos:

EDIT: this things rocks on vocals and bass and guitars ... but you know that already

buschfsu

Well-known member

guys i only want to build one channel with this board. do i have to modify the psu for the reduced current load or will it be fine.

thanks

thanks

buschfsu said:guys i only want to build one channel with this board. do i have to modify the psu for the reduced current load or will it be fine.

thanks

works fine with one channel populated here (no tubes or t4b on the left channel)... the regulator gets really hot though, but it's been running well for 2 days, several hours per day.. don't know if this is a permanent solution, but it works for me. I'll be populating the rest though when I get another output transformer.

I haven't done any sweeping yet (have to get rightmark..) but with an a-24 at the output do I need termination?

EDIT: Well, actually...

This looks pretty good, no? I get a good bit of 50cycle hum, but that's just my sloppy experimental wiring.

EDIT: Well, actually...

This looks pretty good, no? I get a good bit of 50cycle hum, but that's just my sloppy experimental wiring.

benlindell

Well-known member

Hey guys, I'm starting to wire my first unit up. Couple Questions before I get too far:

1. The Gain and Peak pots, I assume the wiper is in the middle on the board, I usually use the shield for the wiper.

2. The Stereo Link switch, I just connect the left pin of each one together with a switch, and the right straight to each other?

3. the GAIN RED switch toggles Gain Reduction and Output I assume

I think that's it for now, thanks for all the help guys.

1. The Gain and Peak pots, I assume the wiper is in the middle on the board, I usually use the shield for the wiper.

2. The Stereo Link switch, I just connect the left pin of each one together with a switch, and the right straight to each other?

3. the GAIN RED switch toggles Gain Reduction and Output I assume

I think that's it for now, thanks for all the help guys.

Latest posts

-

-

-

AKG Perception P220 to Neumann u87 5 min mod ( p200, p100, p400, p420? )

- Latest: Masiusima13

-

-

-

-

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)