ciscan.81

Active member

Here are some pics of a 'from-scratch' ribbon mic I built last year...nothing ground breaking but I like it.

I got some advice from ribbon mic community here (notably Stewart) and promised some pics of the completed build...that was some time ago...

Anyway here they are:

shiny!!! Body 38mm mild steel tube, end caps lathed from solid mild steel - nickel plated

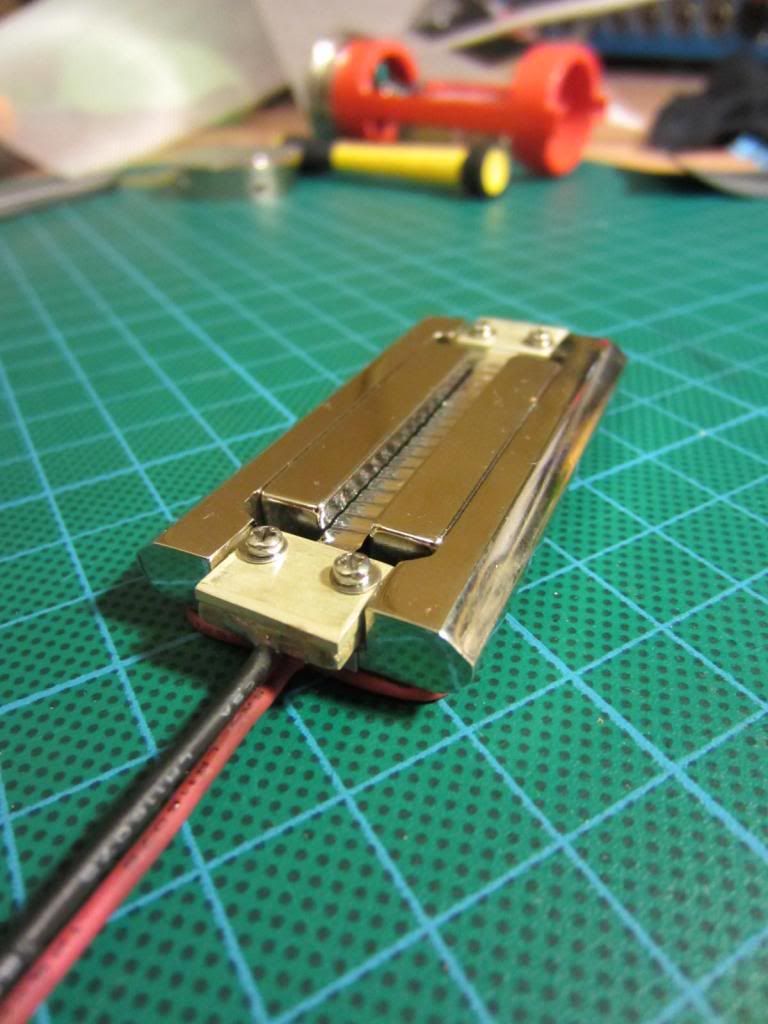

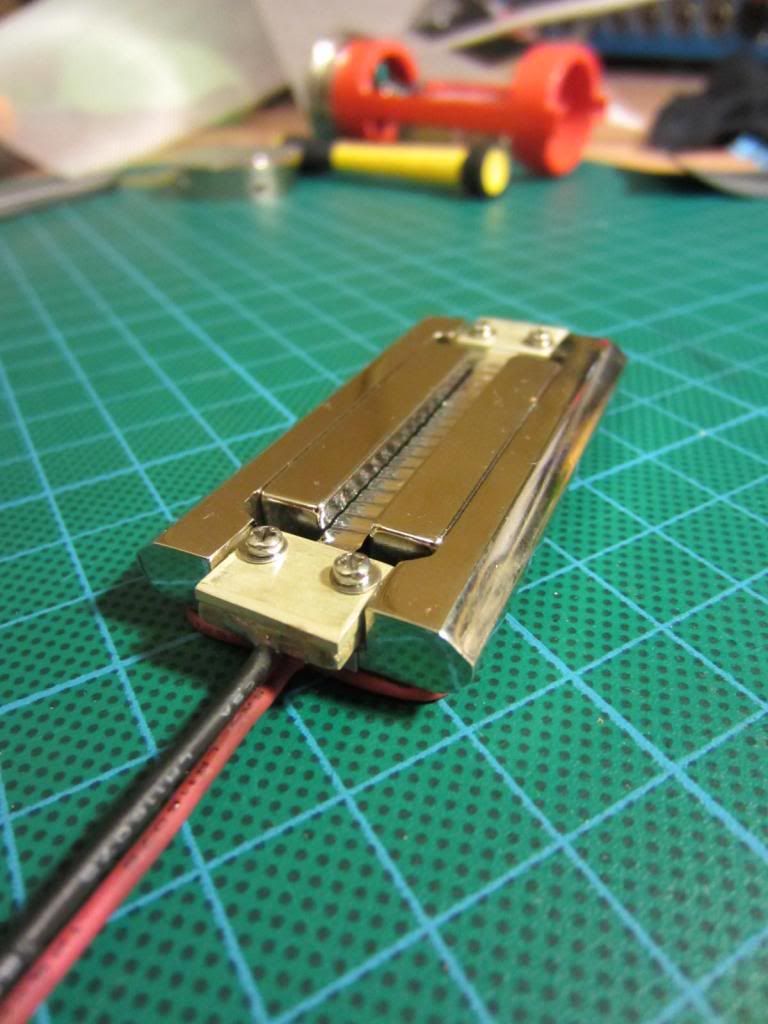

Front of offset-style ribbon transducer milled from mild steel and nickel plated

with SS filter mesh

back showing 1mm solid copper humbucking wires - overkill?

bracket carved from pvc electrical conduit to hold lundahl transformer and transducer

Anyway I am really happy with the look and sound of the mic and enjoyed the learning experience.

Thanks again to the ribbon community here for all the great info posted in discussion forums.

-Wayne

I got some advice from ribbon mic community here (notably Stewart) and promised some pics of the completed build...that was some time ago...

Anyway here they are:

shiny!!! Body 38mm mild steel tube, end caps lathed from solid mild steel - nickel plated

Front of offset-style ribbon transducer milled from mild steel and nickel plated

with SS filter mesh

back showing 1mm solid copper humbucking wires - overkill?

bracket carved from pvc electrical conduit to hold lundahl transformer and transducer

Anyway I am really happy with the look and sound of the mic and enjoyed the learning experience.

Thanks again to the ribbon community here for all the great info posted in discussion forums.

-Wayne