moamps said:

A well-known manufacturer does not share the same philosophy in one of its products (3000 € or $).

As some other manufacturers, and them they make something that is called "The Pin 1 Problem"

This problem has been well discussed.

This is a good reading:

https://www.ranecommercial.com/kb_article.php?article=2127

The "Pin 1" Problem

Many audio manufacturers, consciously or unconsciously, connect balanced shields to audio signal ground; pin 1 for 3-pin (XLR-type) connectors, the sleeve on 1/4" (6.35mm) jacks. Any currents induced into the shield modulate the ground where the shield is terminated. This also modulates the signal referenced to that ground. Normally great pains are taken by circuit designers to ensure "clean and quiet" audio signal grounds. It is surprising that the practice of draining noisy shield currents to audio signal ground is so widespread. Amazingly enough, acceptable performance in some systems is achievable, further providing confidence for the manufacturer to continue this improper practice -- unfortunately for the unwitting user. The hum and buzz problems inherent in balanced systems with signal-grounded shields has given balanced equipment a bad reputation. This has created great confusion and apprehension among users, system designers as well as equipment designers.

Similar to the "pin 2 is hot" issue, manufacturers have created the need for users to solve this design inconsistency. Until manufacturers provide a proper form of interconnection uniformity, users will have to continue their struggle for hum-free systems, incorporating previously unthinkable practices.

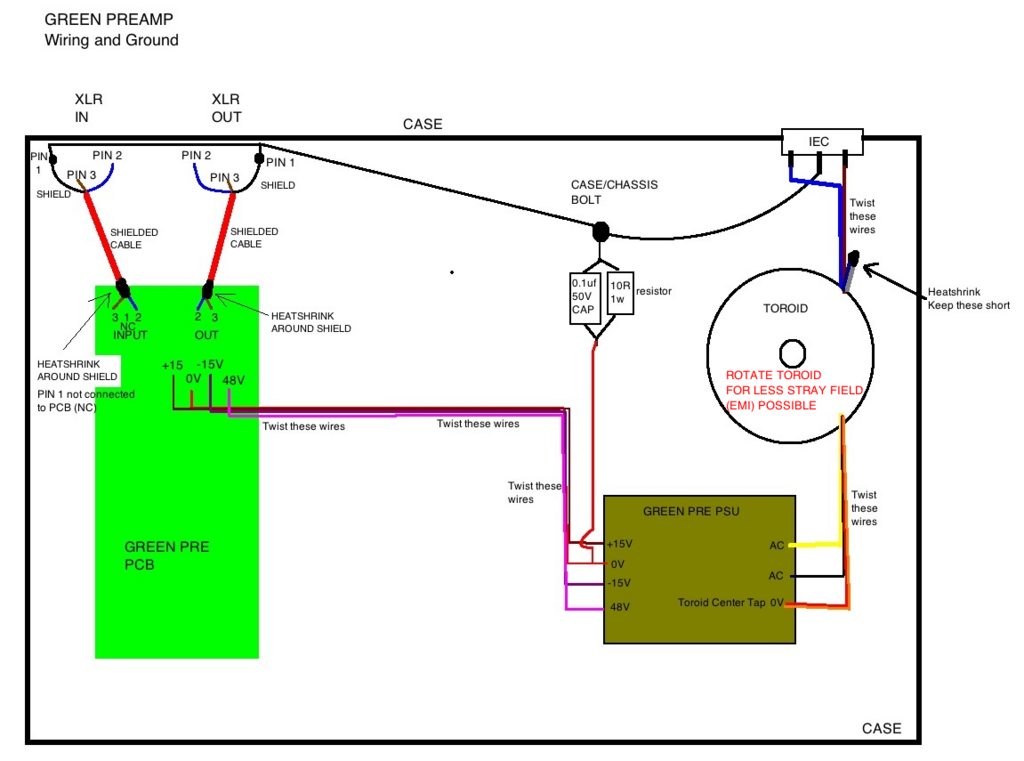

The Absolutely Best Right Way to Do It

Clearly, the available literature prescribes balanced interconnection as the absolute best way to interconnect audio equipment. The use of entirely balanced interconnection with both ends of the shield connected to chassis ground at the point of entry provides the best available performance.

The reasons for this are clear and have been well-documented for over 60 years. Using this scheme, with high-quality I/O stages, guarantees hum-free results. This scheme differs from current practices in that most manufacturers connect balanced shields to signal ground, and most users alter their system wiring so only one end of the shield is connected. Due to these varied manufacturer and user design structures, an all-encompassing recommendation with proper coverage of both balanced and unbalanced interconnection is essential.

Conceptually, it is easiest to think of shields as an extension of the interconnected units' boxes (see Figure 1). Usually, metallic boxes are used to surround audio electronics. This metal "shell" functions as a shield, keeping electromagnetic fields in and out of the enclosure. For safety reasons, the enclosures in professional installations are required by law to connect to the system's earth ground (which in many systems is not the planet Earth -- an airplane is a good example).

Balanced cable shields should function as an extension of the enclosure.

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)