Yes your right Mad , Id forgotten about that one , I see theres a fan to help out with cooling too.

I have the 20 watt Marshall Pa amp from the early 70's , I replaced the dropper resistor in the screen supply with a choke which gave it a more rounded punch on the peaks . I added the treble leak cap across pot on one channel so its the same as the lead 20W in terms of tone . I also made a change to the phase invertor so its more like the 50W circuit without the feedback connection . I think I changed the value of the tail resistor to 15k and added the usual 470 ohm grid dropper with two 1M connected to each grid with a 0.1uf decoupling cap to ground from the second grid . That amp ate tubes until I gave it the traditional 'standby' switch found on bigger amps of its kind . I lifted the centre tap of the HT winding via a toggle switch at the back for convienience of wiring ,it also doesnt create a major bump in the sound output when its turned on or off , merely a slight rushing sound of electrons to the plates reflected into the speaker .

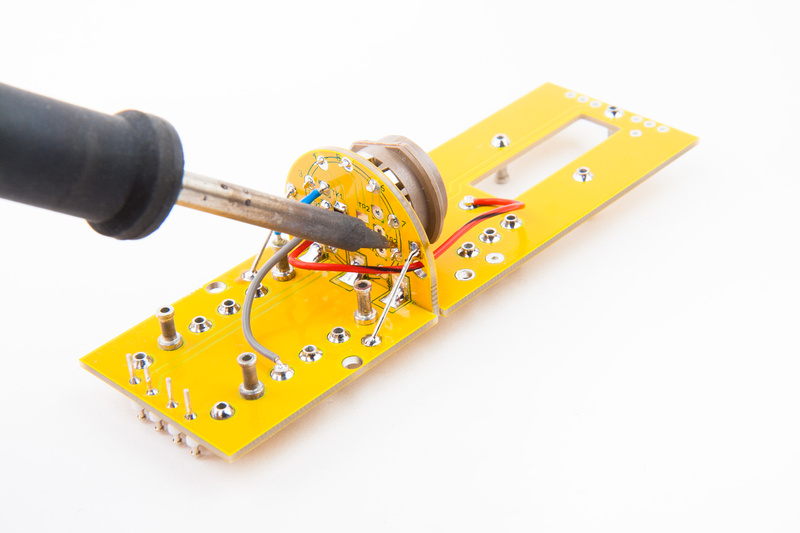

I've seen several amps with power tubes mounted vertically on the PCB , it can be problematic ,over the years the weight of the tubes and the heat tends to warp the PCB and its more prone to scorching/arching than hardwire , . Fender does it well in it in the blues deville/deluxe type amps and the only issue ive found is when musicians try and change a tube mid gig and break the soldering to the socket .

Definately a fan of angle iron brackets for tube mounts with hardwire ,

I grabbed a 10 pack of zinc plated 90 degree structural steel brackets from Lidl for 3.99 euros ,

I clamp it up in a vice and drill out the centre hole to the diameter of the tube socket ,I then mark the mounting holes for the tube socket ,punch then drill the results are faultless every time .

The brackets are 2mm thick , way overkill but it helps conduct heat from the tube to the relatively cold chassis very efficiently .

Bullet holing the panel above and below the tube in a 1U enclosure is always a good plan , but remember to allow some space between adjacent units for air flow . You see this technique used on the tube Danner enclosure/V series, a punched air vent in the vicinity of the tube allowing good air flow up through the enclosure.