- Joined

- Jul 15, 2009

- Messages

- 2,306

D-U67 Build Thread

Let's get those Electron flowing.

All of the info: http://www.groupdiy.com/index.php?topic=49675.0

The D-U67 Tube Mic

Mic Assembly Tutorial

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a0351f.pdf

PSU Assembly and Tips

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a03549.pdf

http:// Check this First: Project Files for The D-U67 Build

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a0356c.zip

The Safety Manual and Considerations.

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a0357d.pdf

IMPORTANT:

You Should always have the SHLF Jumper in position in the PSU PCB , this will ensure that your cable shield is tied at both end of the cable and connect to 0V

you Should Also have the 0V star grounded to your case and then from there to you IEC earth ground ,

For More Information on Grounding

https://www.dropbox.com/s/6y121dasm3iw4ba/Sound_System_Interconnection.pdf?dl=0

Best,

Dan,

D-U67 Mic Parts: http://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=83ad963d23

Note: BOM include 56R For R20

D-U67 PSU Parts : http://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=b5c122b4d0

Note: BOM include 560R for R9

OK , here is the briefing

For More Information on Grounding

https://www.dropbox.com/s/6y121dasm3iw4ba/Sound_System_Interconnection.pdf?dl=0

i always have the habit of never float 0V on a PSU i always star ground it to the chassis and then IEC plug ,

about the shield it is imperative at all time that the shield has a path to the chassis as well so it will protect YOU and Your investment. in the mic PCB the shield and 0v are on the same level meaning they are connected togheter and the mouting hole of the pcb are connected to the chassis , this lead to always have the shield protecting you because i ALWAYS star Ground 0V to the power supply case so in all everything always goes to the earth no matter what , So in essence this SHLF is somthing i wanted to implement as a ground lift but it was not done properly and i am glad it turned that way because it is safe this way ,

i guess i am an habit person i always did it like this and never had any problem.

if you have hum problem you can start floating thing arroundb like the 0V from PSU to in respect to Chassis or the shield but it is very something of last resort and i dont recommend it as it is to me potentially unsafe to do so ,

Hope this helps, above is a good read about how to properly ground the equipment togheter,

best,

Dan,

Important Note

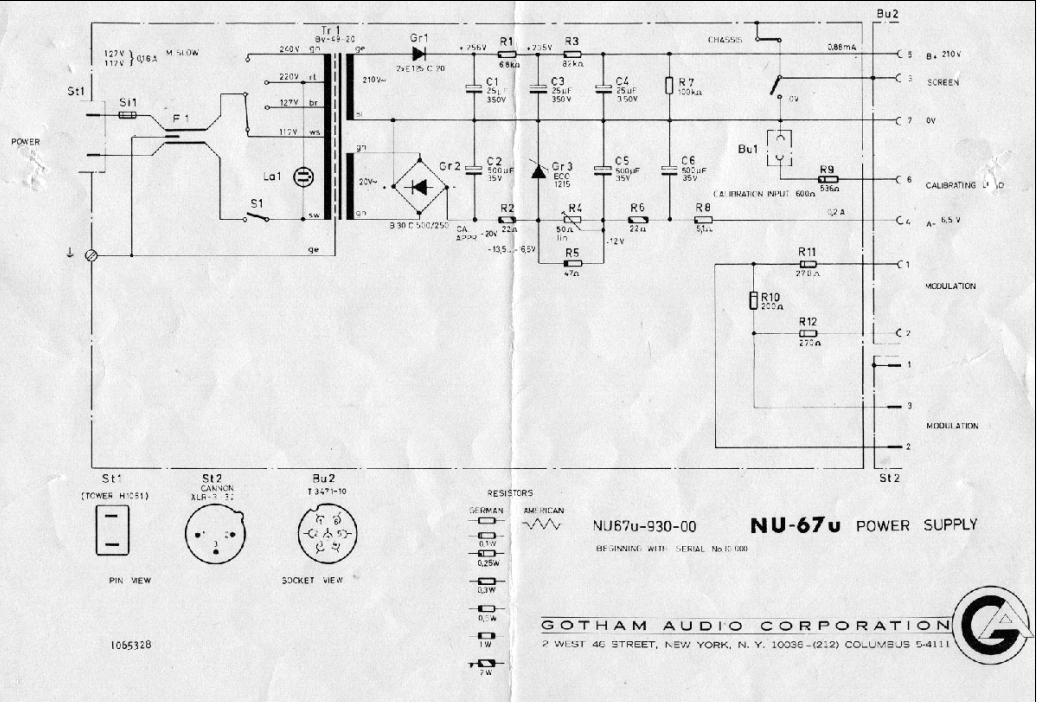

Update on PSU Power Specification

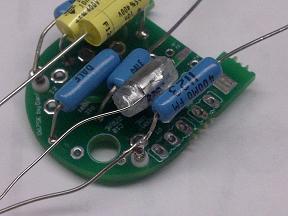

Problem : R2 is getting way too hot

it has been brought to my attention that the PSU Power Supply (R2) Power was out of tolerance and heating passed its

ratings. this has been very isolated case only.

Do Not Use More than 6VA for the 20V transformer

Explanation: the Hammond transformer in the BOM was specified at 300ma 6VA , some DIYER used higher power supply rating cause a bigger Voltage drop in R2 than anticipated supplying more current to it causing the resistor to get too hot and melt the solder on the pcb. those who have used the Specified Hammond transformer can go ahead and only upgrade R2 for the new higher power resistor if needed. Those who have the old hammond transformer should be ok as it cannot outpout enough power to go past 2W specified, only a resistor upgrade is need in this case.

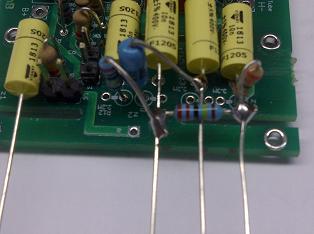

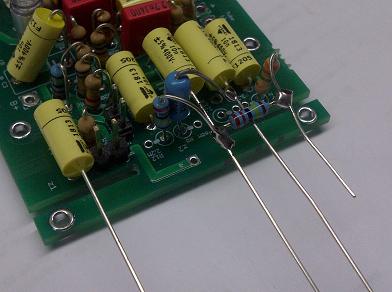

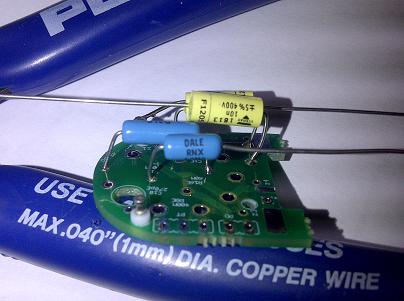

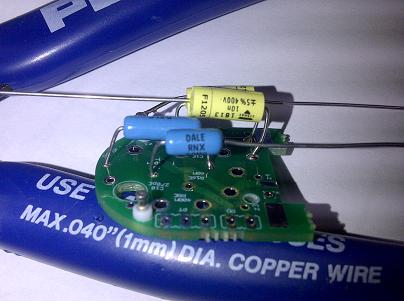

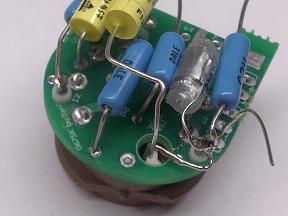

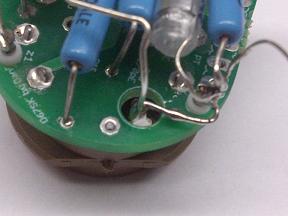

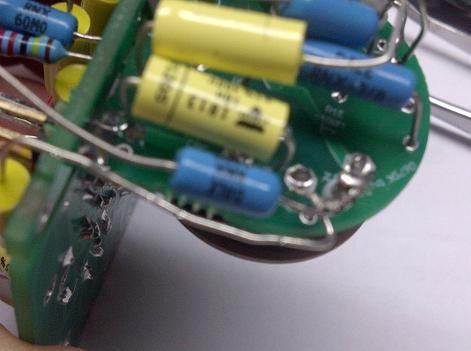

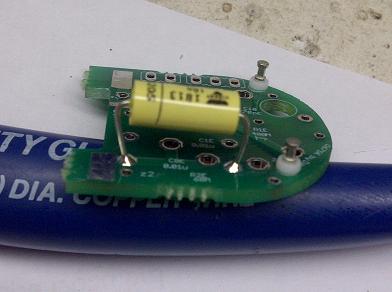

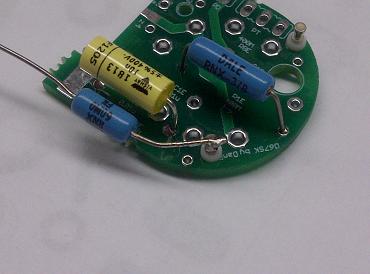

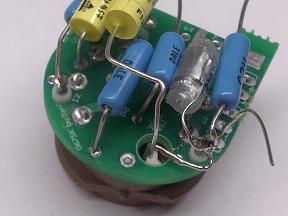

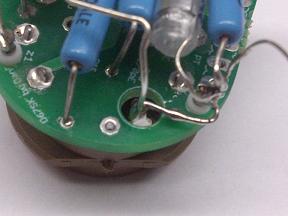

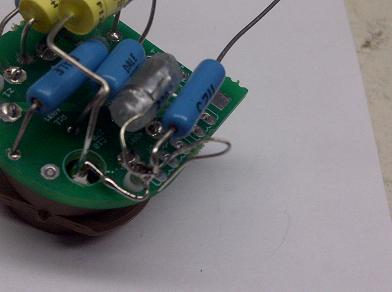

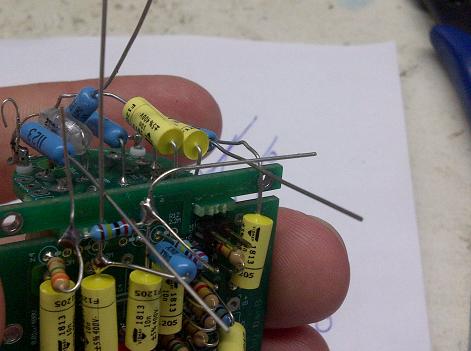

Solution: After Analysis of the power dissipation required on R2 to provide with the Heater Voltage. it has been found that

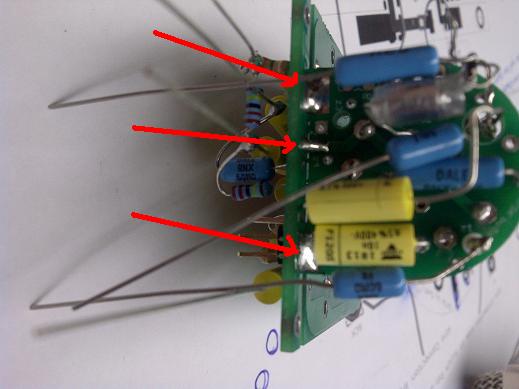

new higher power R2 Resistor 22ohm 5W to alleviate this as well and it will run cooler. it is also recommended that R2 and the Zener diode shall be lifted a little bit from the PCB to permit better heat disspipation to run even cooler :[/b]

Now Included in the BOM

Here is the 2 suggested part for R2 5Watt as well updated in the BOM

http://ca.mouser.com/Search/ProductDetail.aspx?R=RWHSE09TU025R0FSvirtualkey58440000virtualkey605-RWHSE09TU025R0FS

or

http://ca.mouser.com/Search/ProductDetail.aspx?R=AC05000002209JAC00virtualkey59420000virtualkey594-AC05W22R00J

Many Thanks To TLRT for catching those potential issues.

Best,

Dan,

The only 2 parts that is not (Europe 230V) compatible is the hammond 20VAC and the PSU pilot Lamp wich is 120V everything else is fine except the fuse will need to be 0.1A instead of a 0.2A for north America, you will need a minimun 6VA traffo for the filament side,

alternative part number are discussed in this thread here :

http://www.groupdiy.com/index.php?topic=49675.20

http://www.groupdiy.com/index.php?topic=49675.40

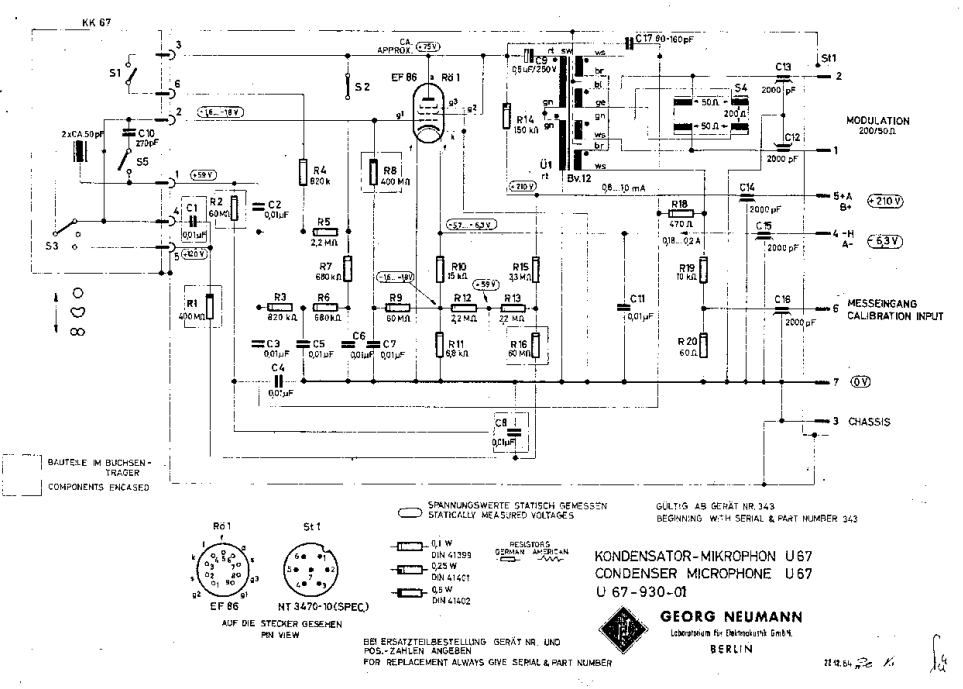

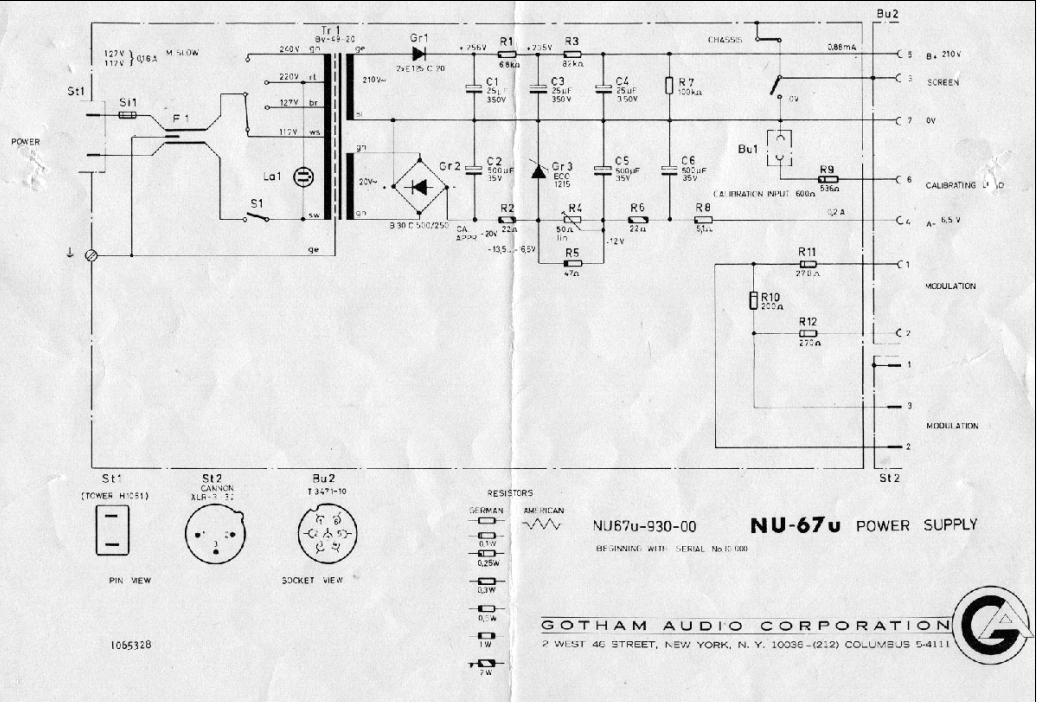

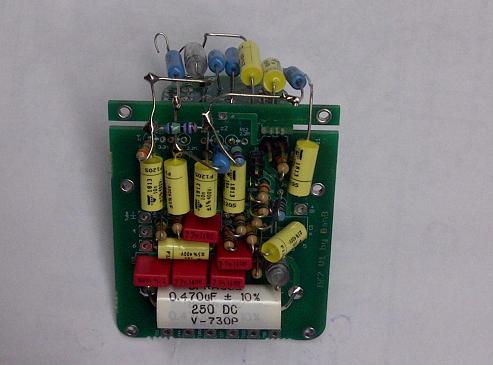

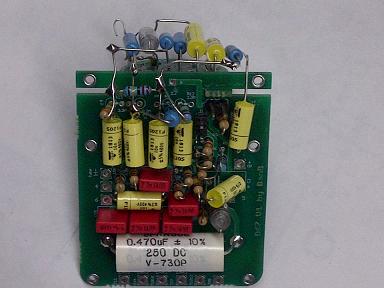

PSU Schematic

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a0358d.pdf

Errata Feedback winding polarity http://groupdiy.com/index.php?topic=50021.800 reply # 814

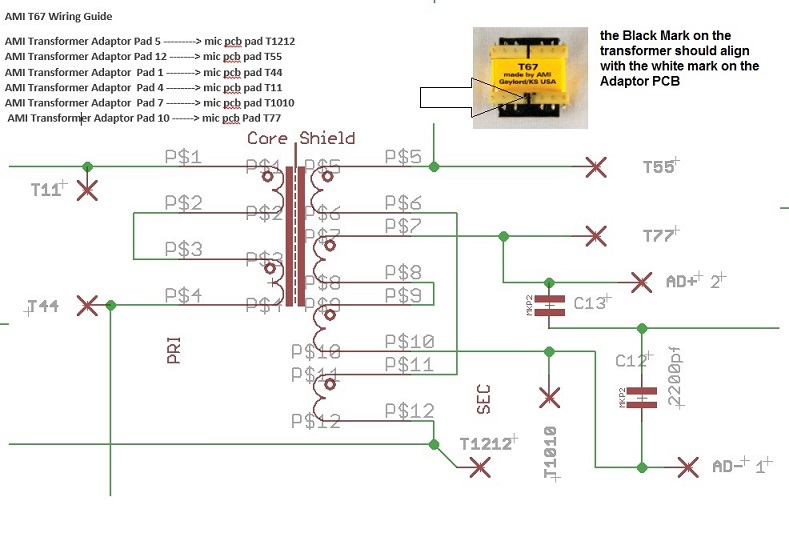

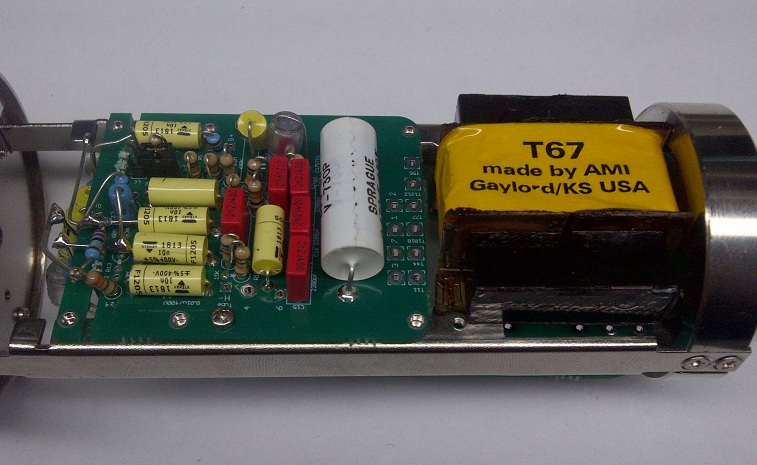

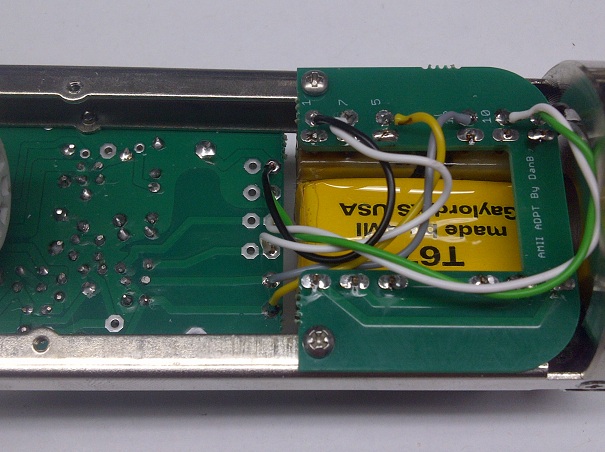

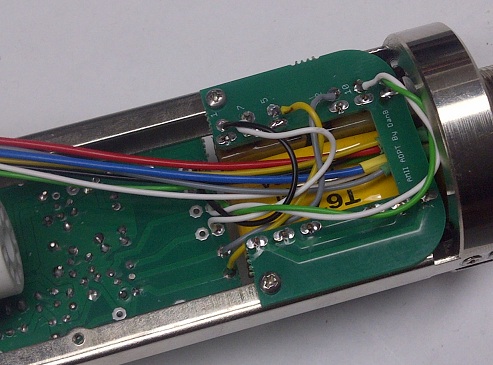

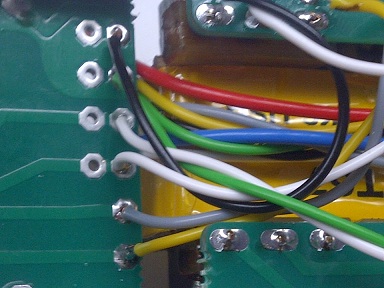

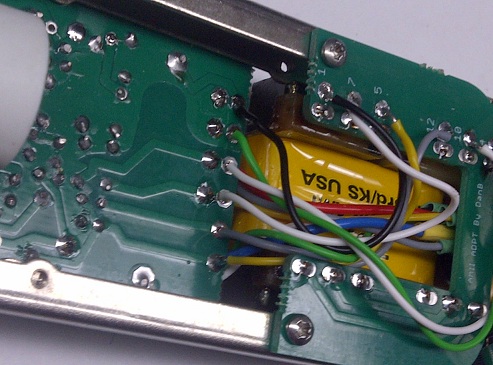

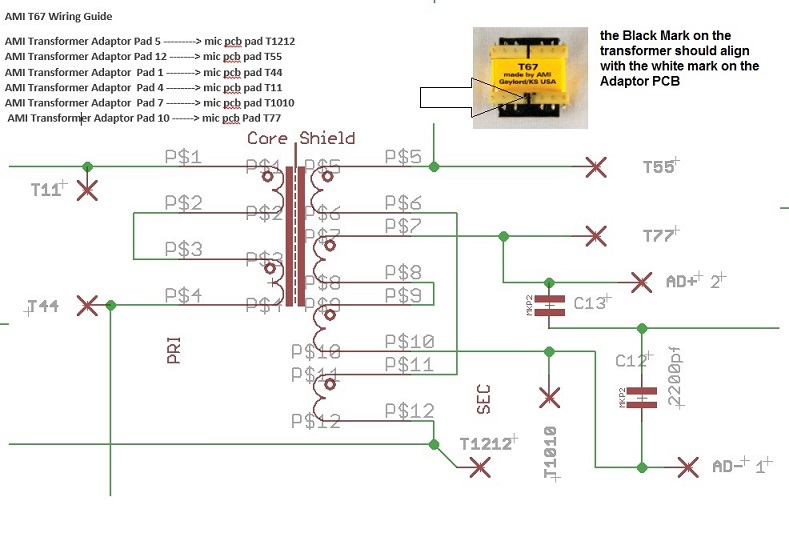

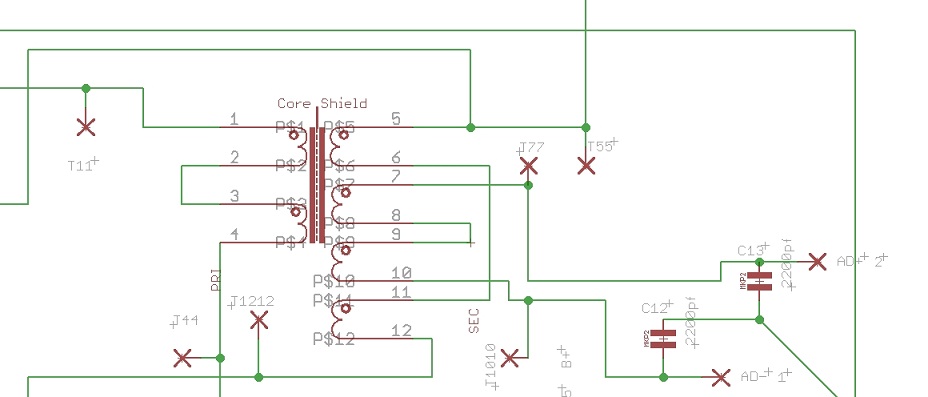

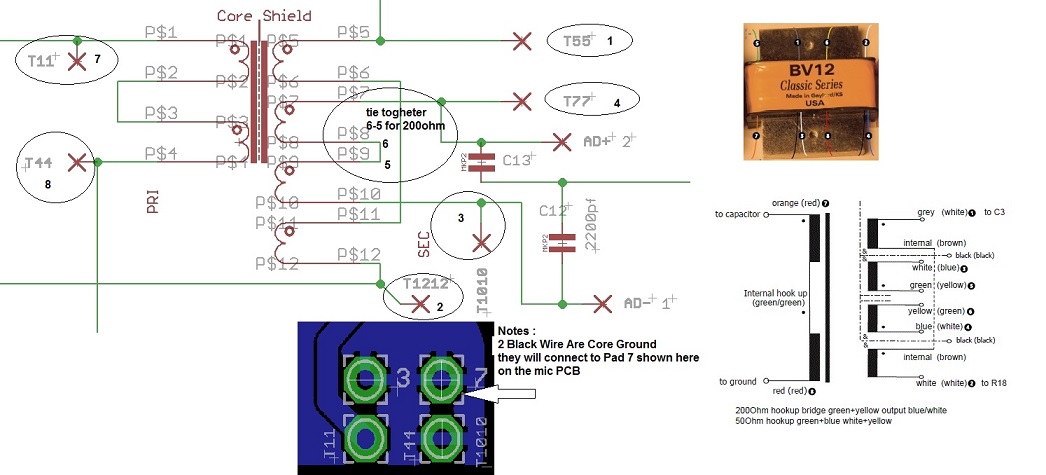

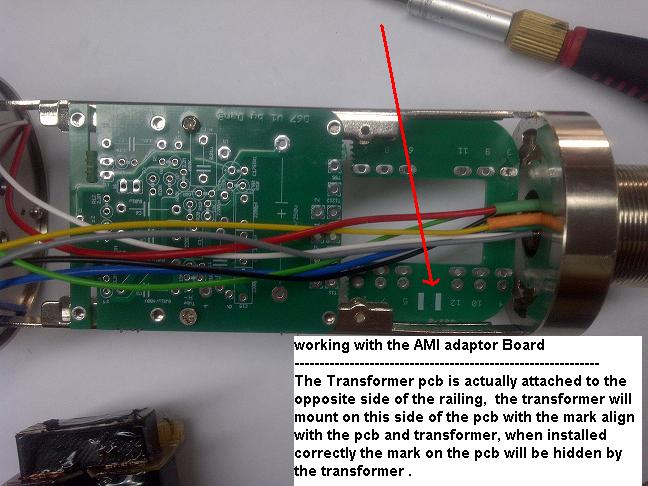

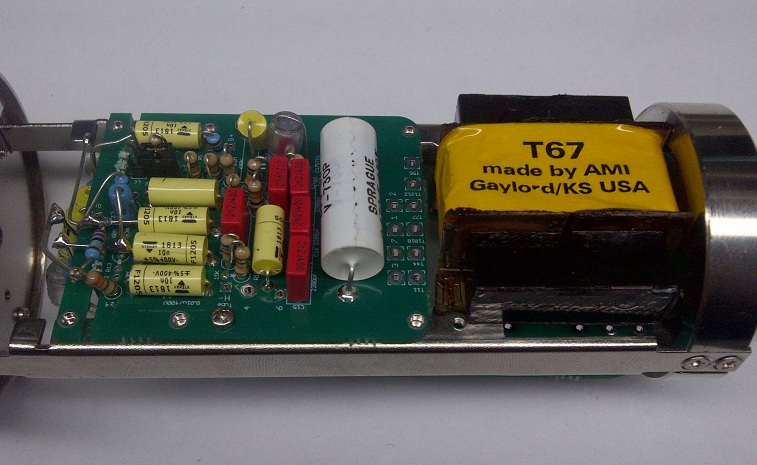

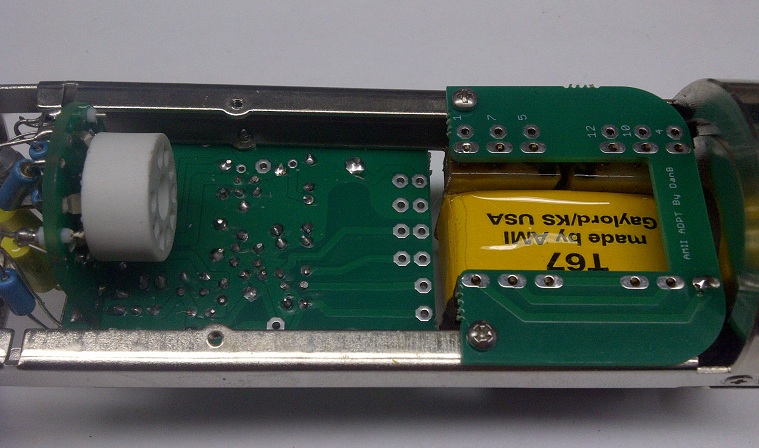

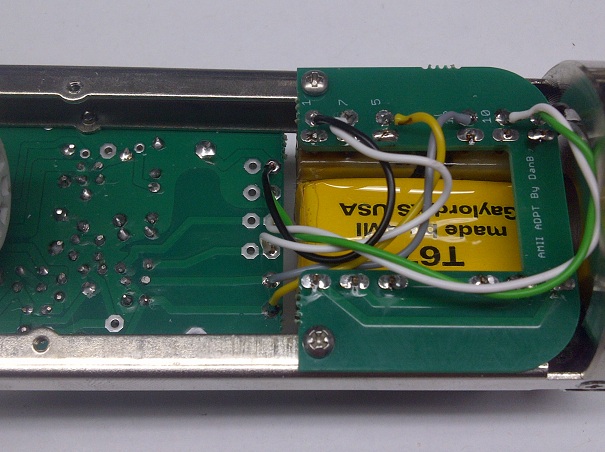

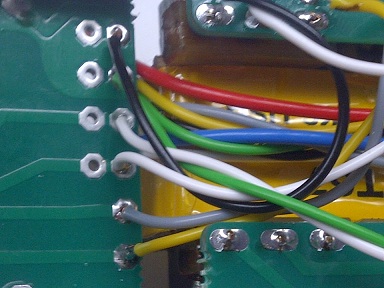

AMI T67 Corrected Wiring to main microphone pcb

From transformer board to mic PCB

Pad 5 -----> mic pcb pad T1212

Pad 12 -------> mic pcb pad T55

Pad 1 --------> mic pcb pad T44

Pad 4 --------> mic pcb pad T11

Pad 7 --------> mic pcb pad T1010

Pad 10 ------> mic pcb Pad T77

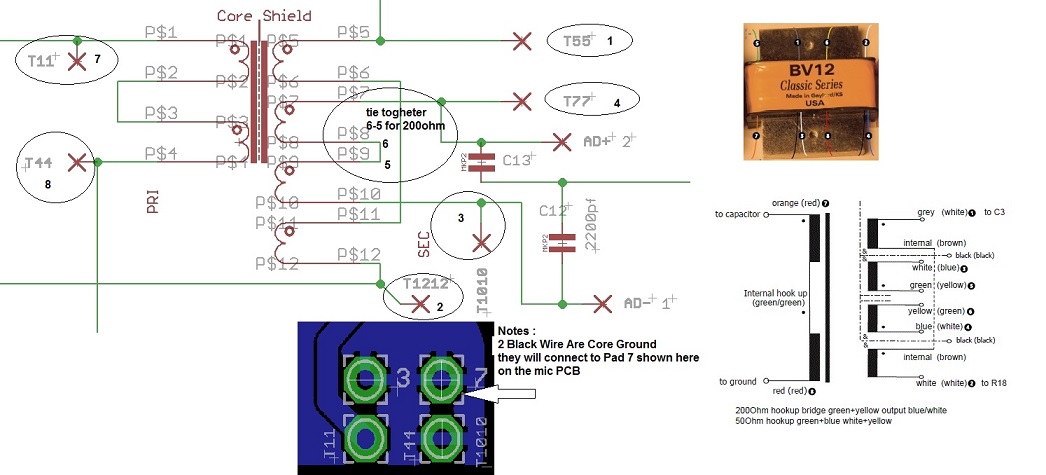

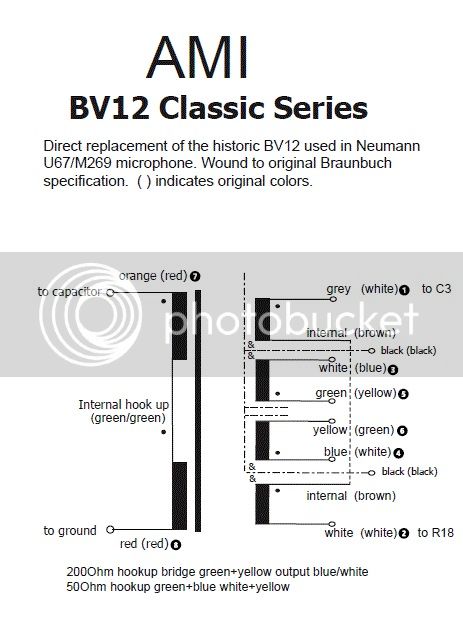

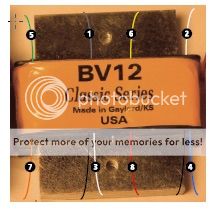

yes i got it this morning , cant wait to start a new build with this traffo. i really like my D-EF47 with the BV8 classic series.

let get this bv12 classic series going

the 2 black wire are actually shiedling of the core, take those 2 wires to a gnd pad onm the pcb,

Also note that the Blue wire (4) is the +audio out and the White (3) is - audio out

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a035c5.pdf

best,

Dan.

See here for complete relationship between pad and transfomer on the AMI mic pcb,

http://groupdiy.com/index.php?topic=50021.msg720336#msg720336

BOM Annexe

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a035d6.doc

Not inclued in the Mouser Bom are:

Styroflex Capacitor Available Here :http://dl.dropbox.com/u/43869772/U67/Picture%20Tron/orderformDU67.xls

Microphone Body and accessories Available Here :http://www.groupdiy.com/index.php?topic=50015.0

Bellow Basic Setup for Different Version , different folks different strokes 8)

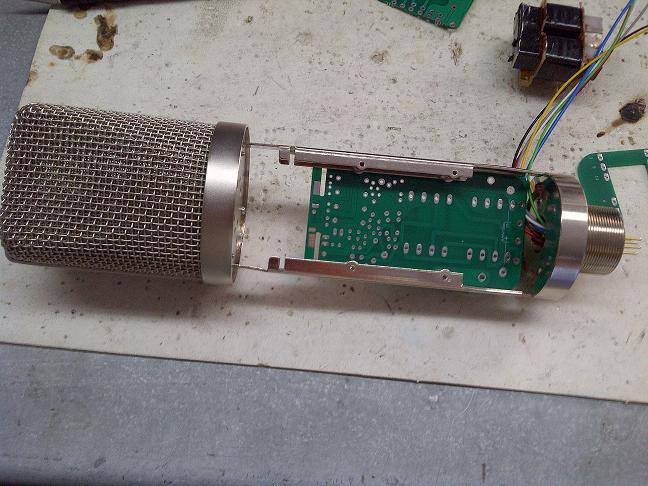

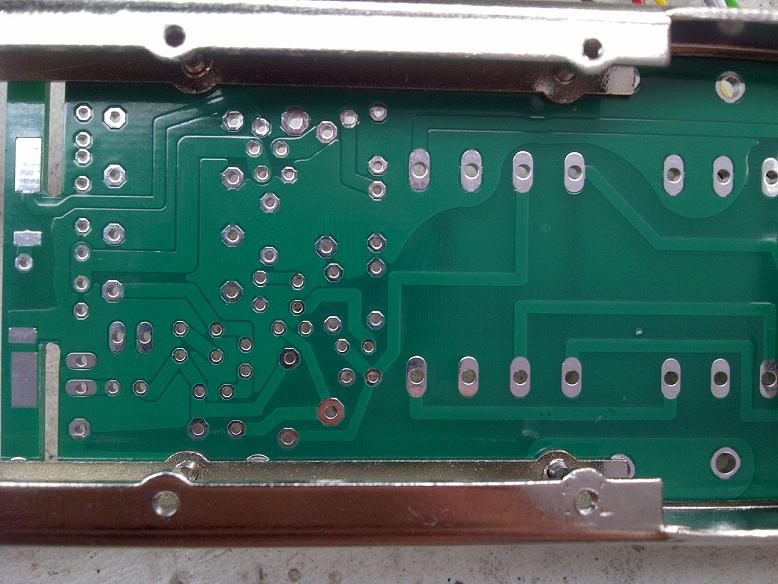

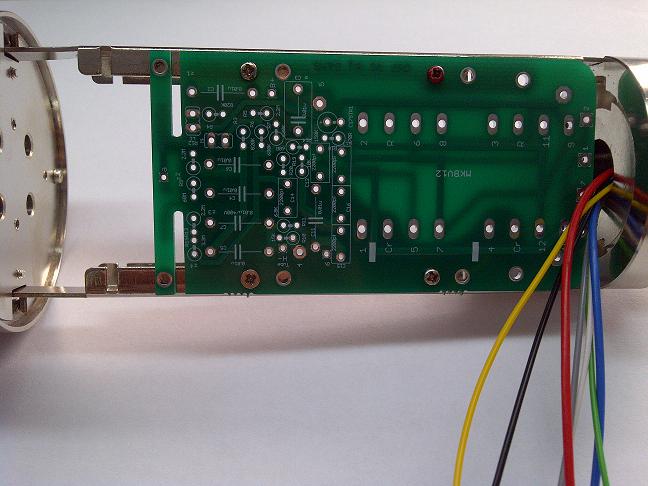

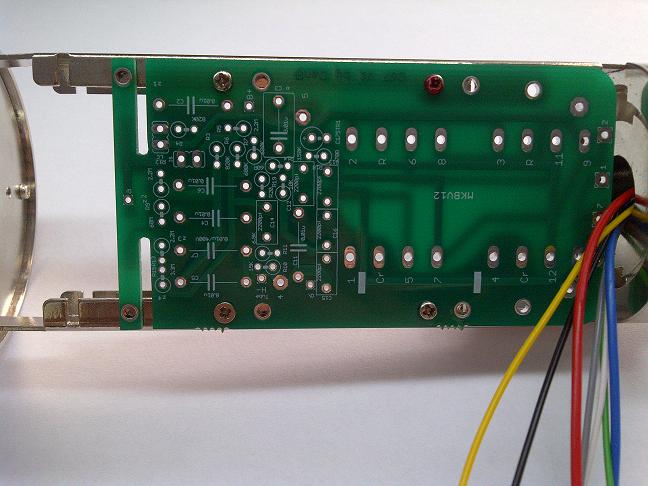

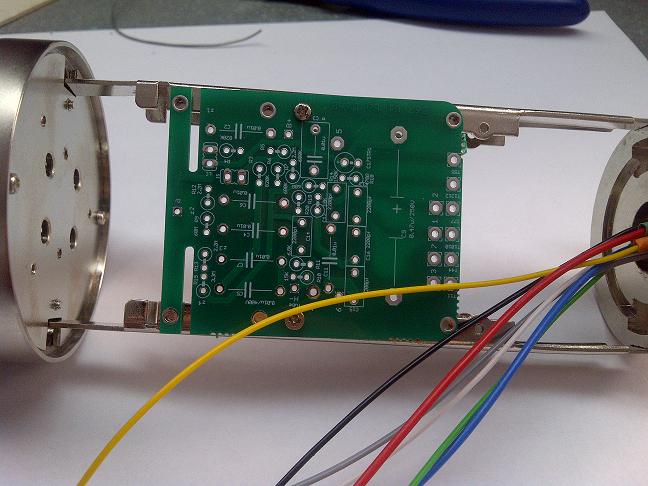

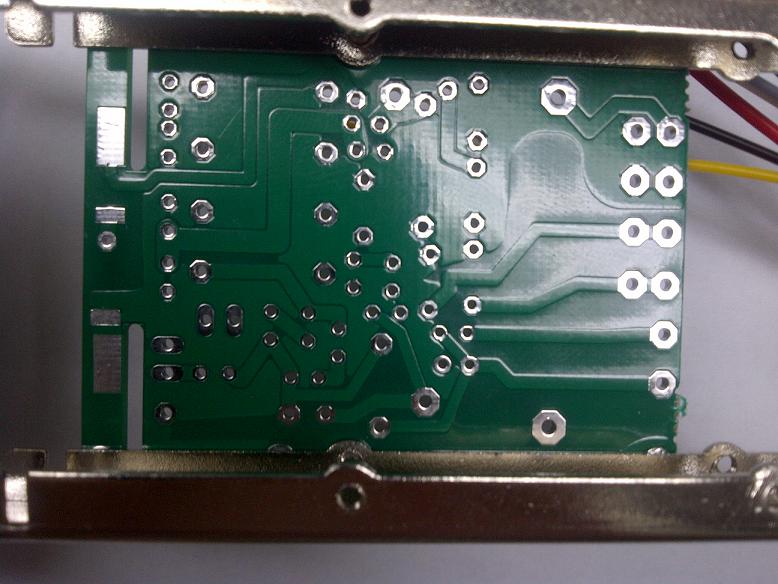

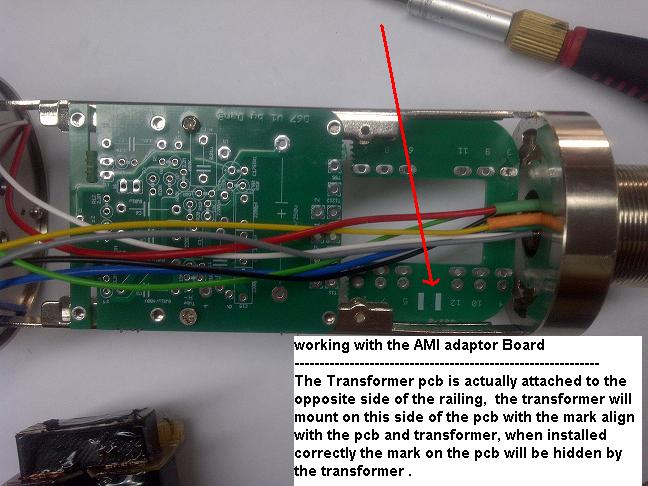

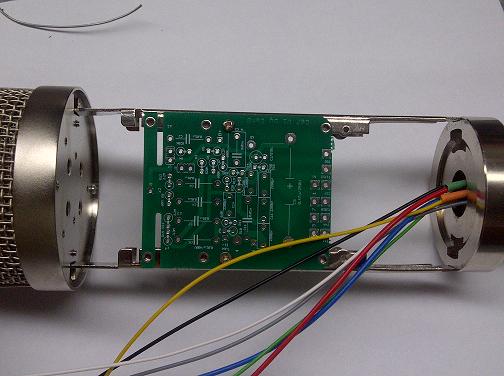

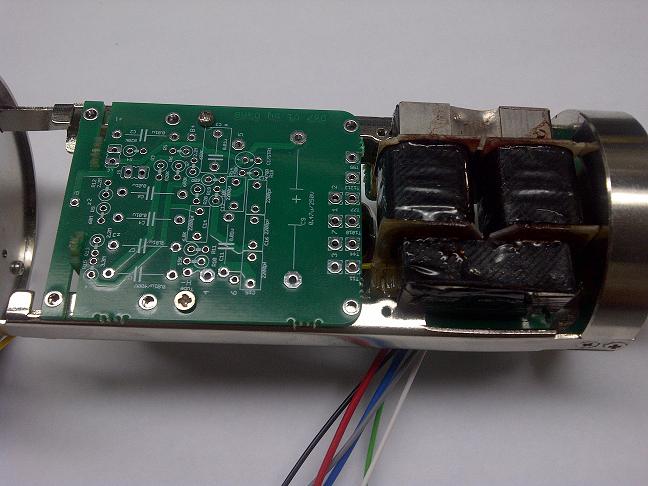

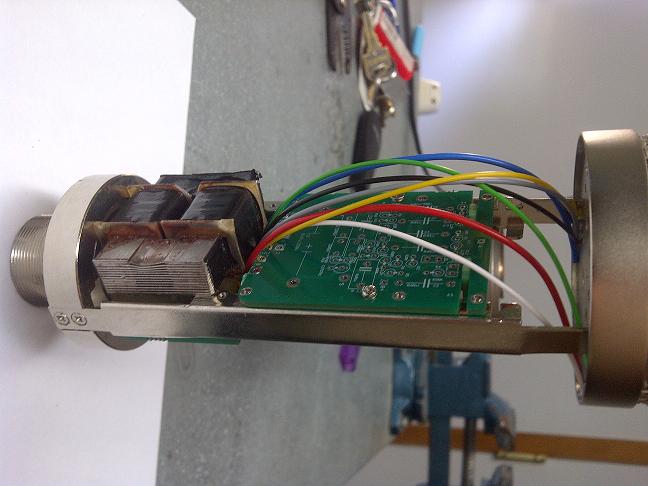

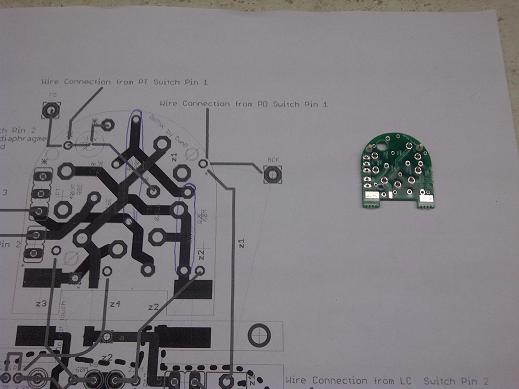

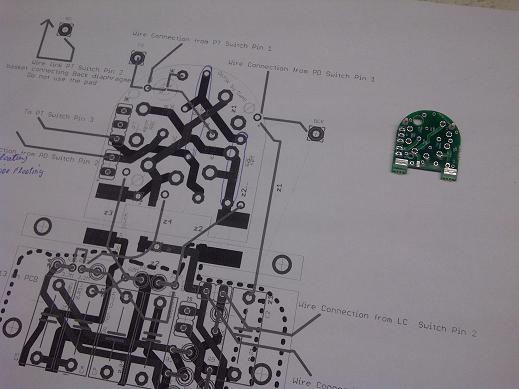

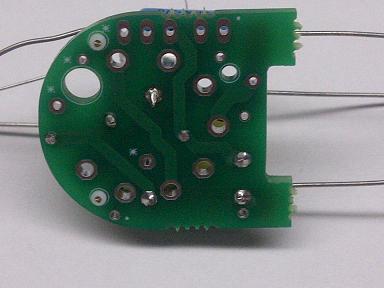

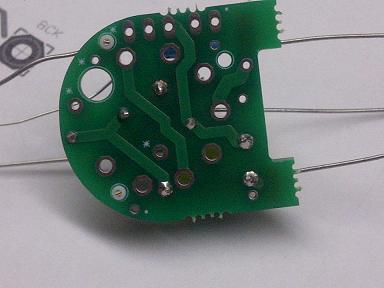

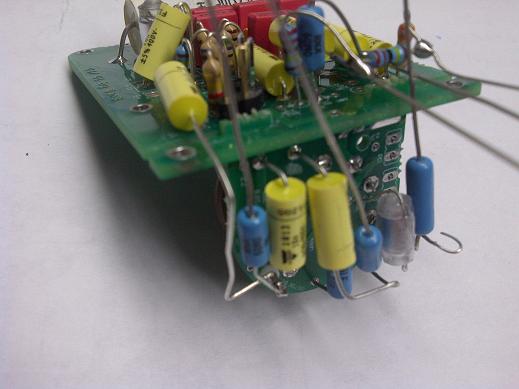

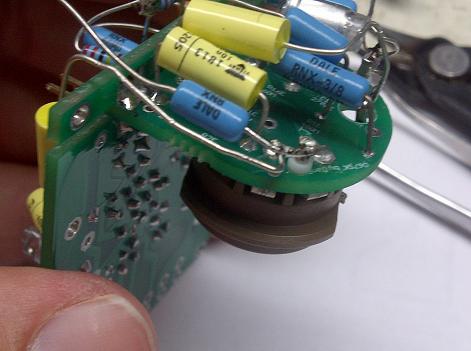

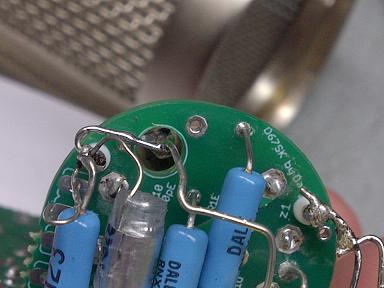

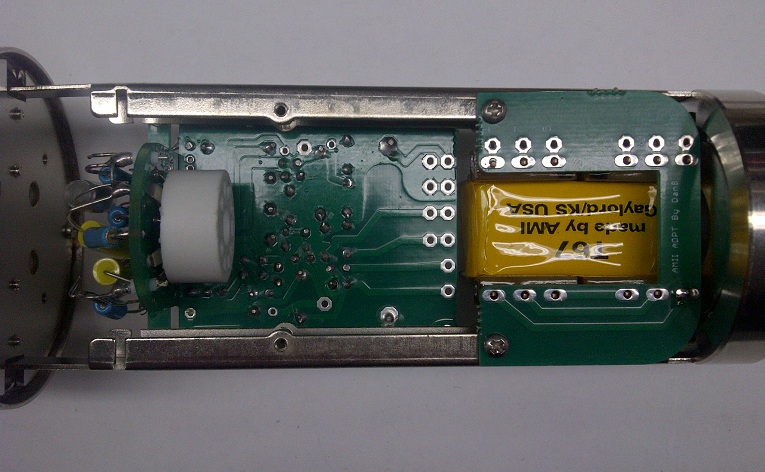

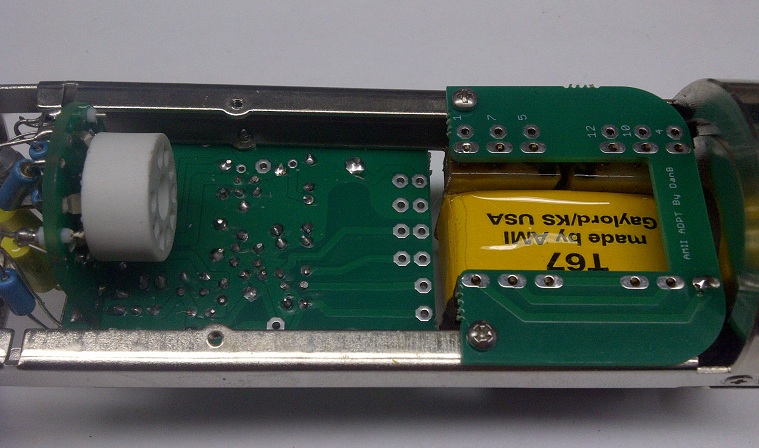

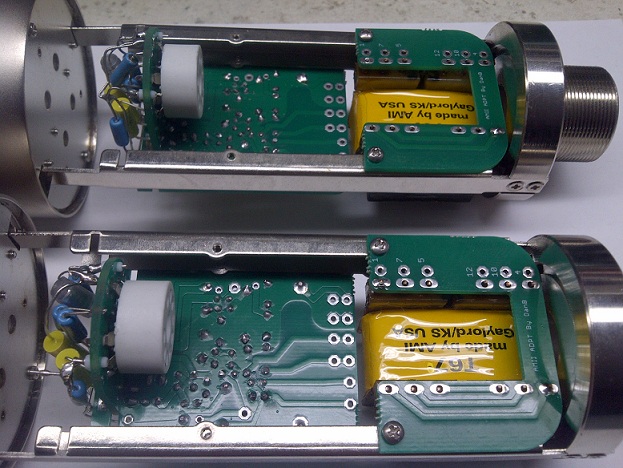

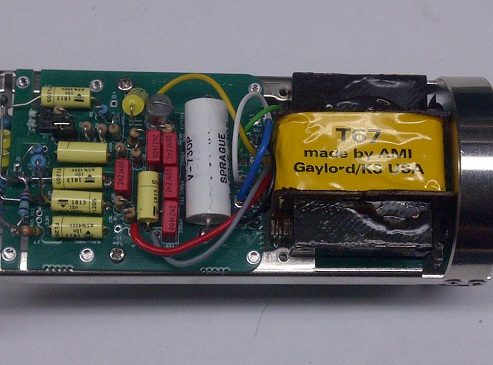

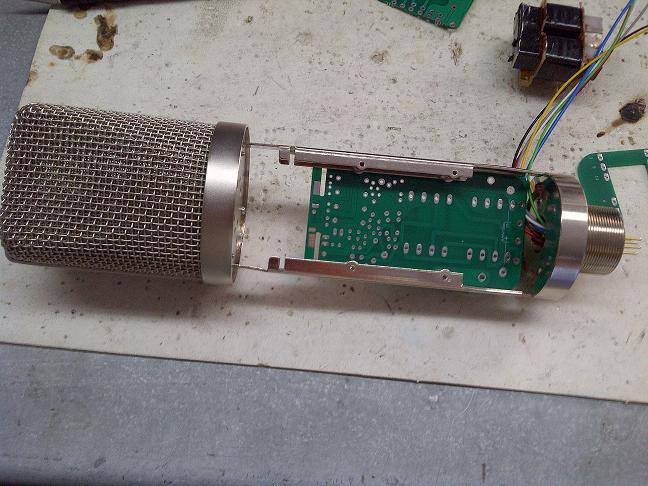

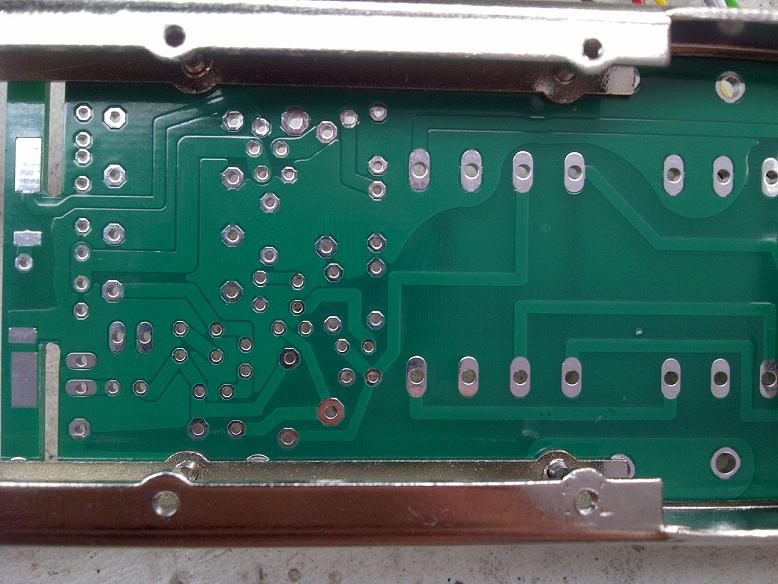

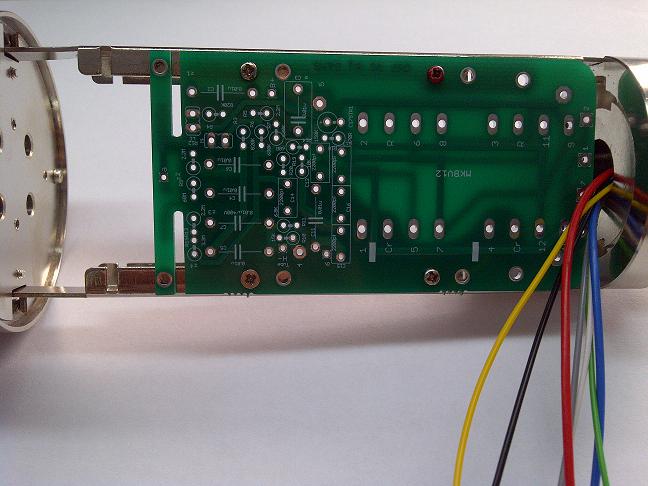

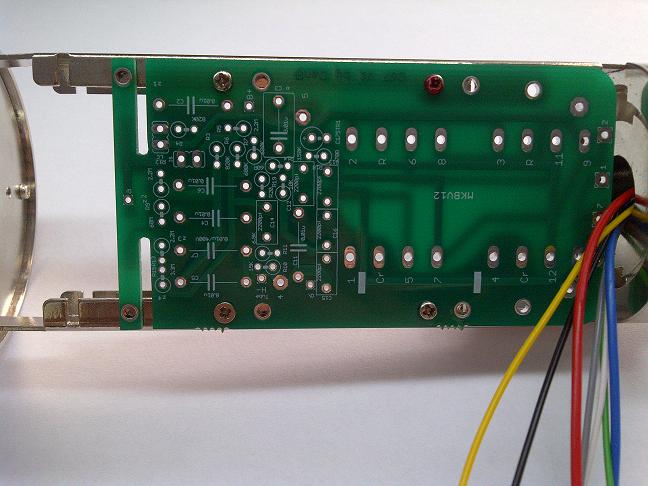

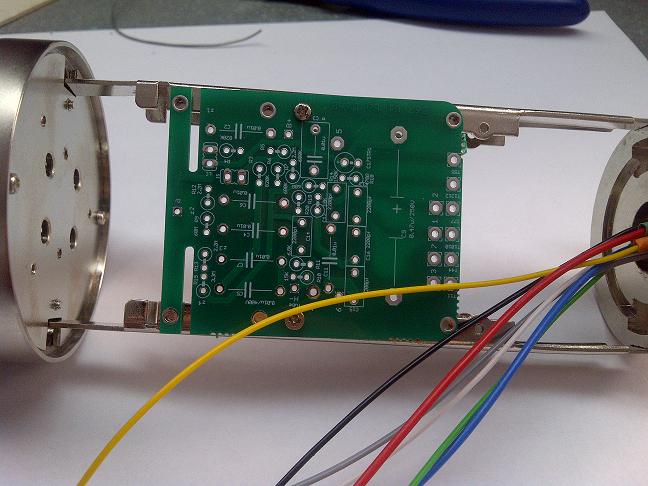

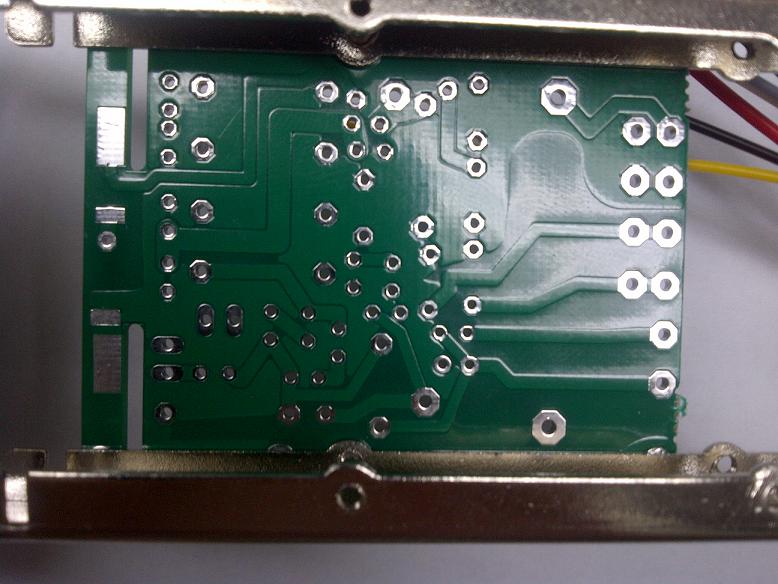

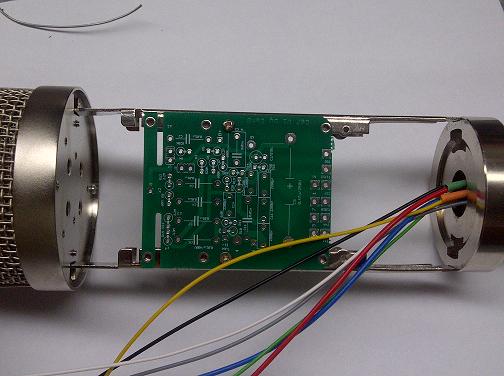

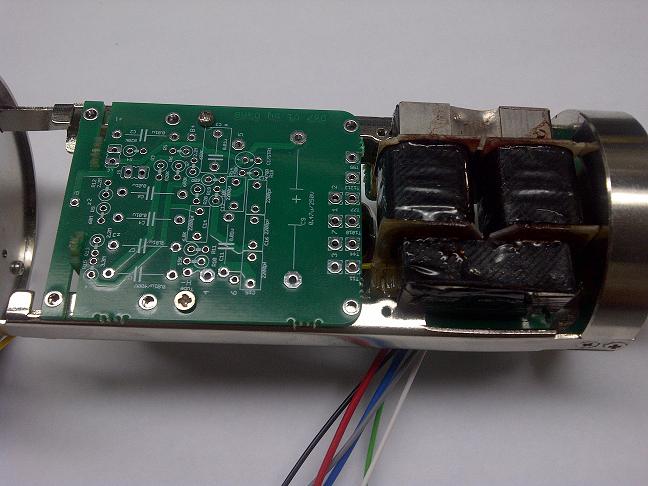

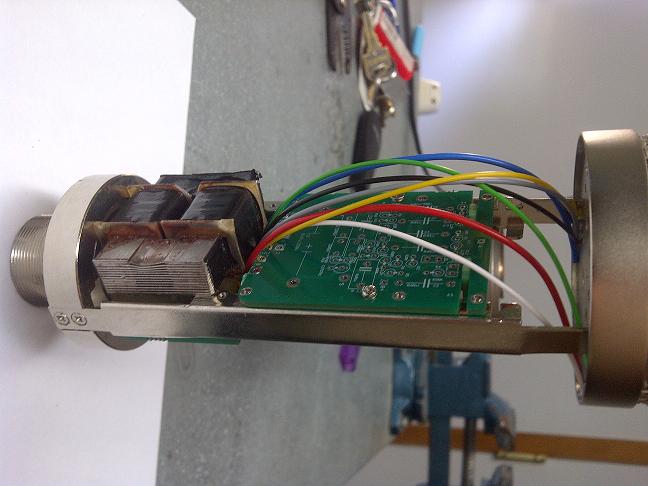

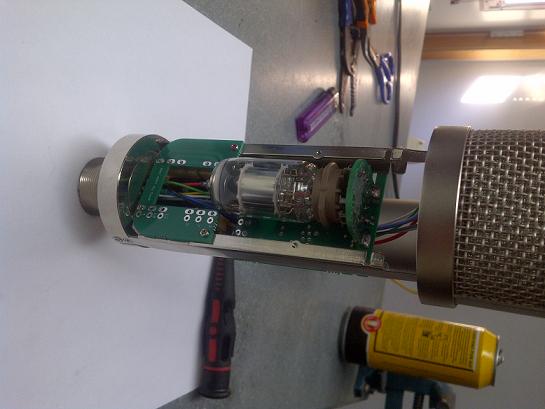

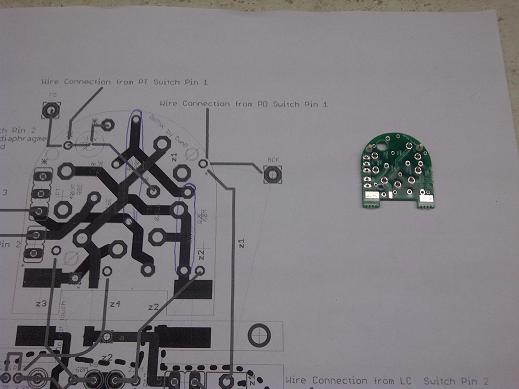

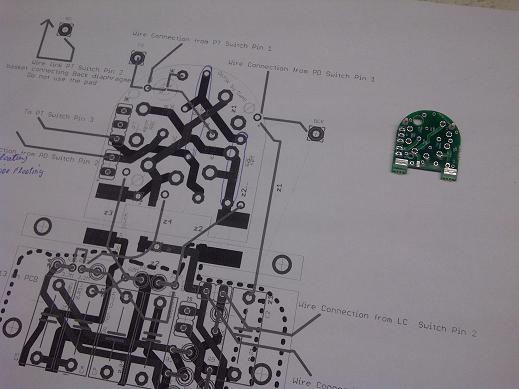

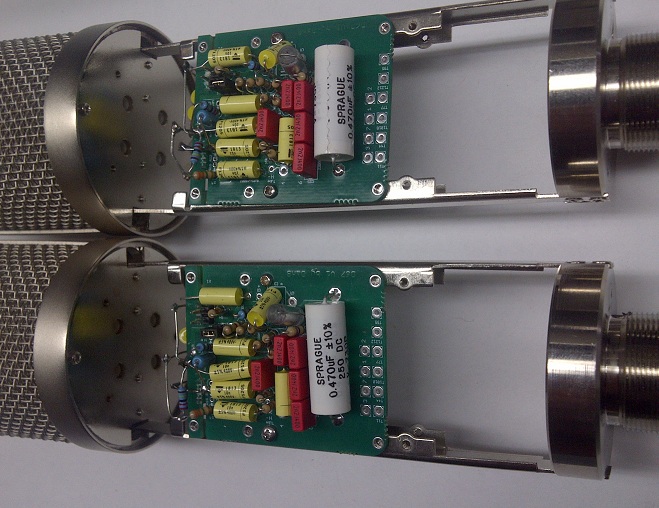

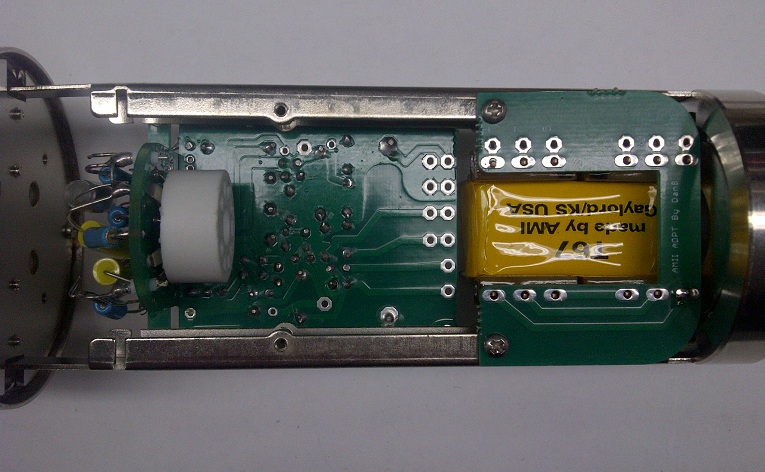

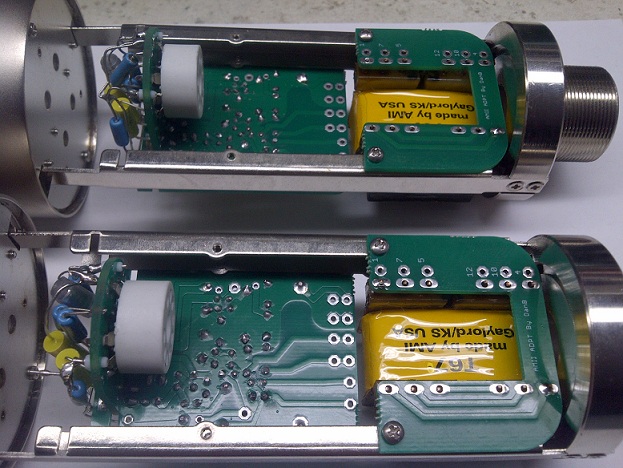

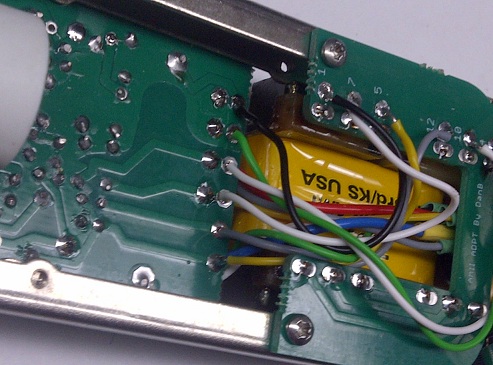

I have been working on validating the last details regarding mouting the AMI boards and last fine tuning regarding the Clearance of the track pad in respect to th railing and position, fit in the mic boady and hole tolerance , I am pleased to annonce that all my concerns on this have been validated ,

here some

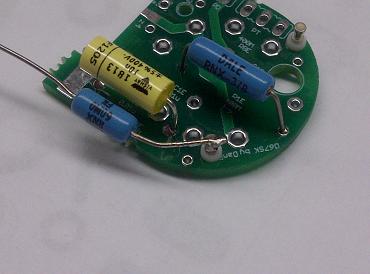

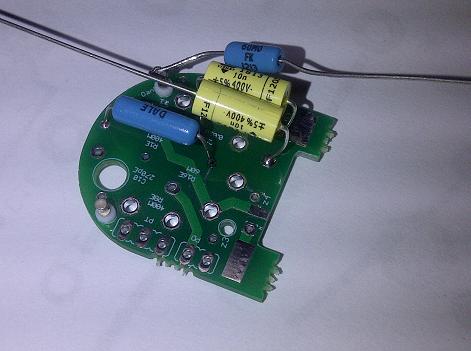

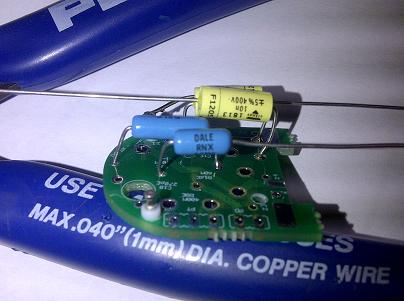

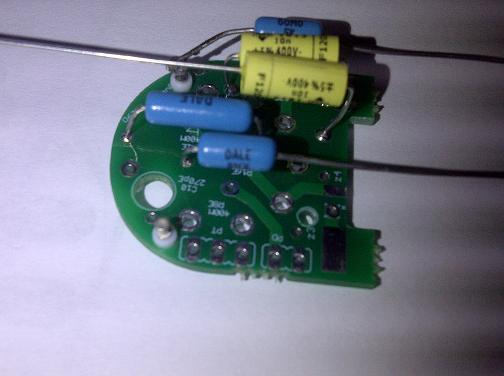

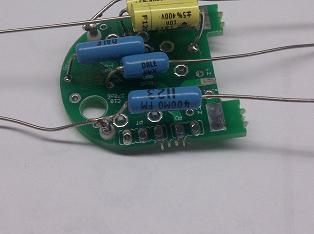

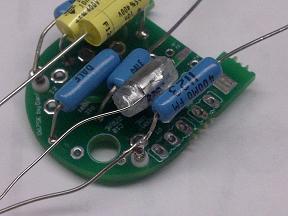

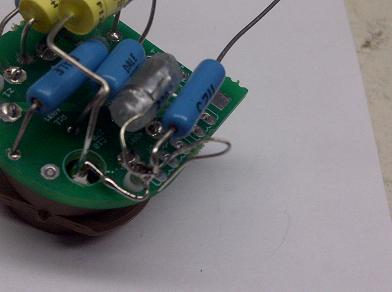

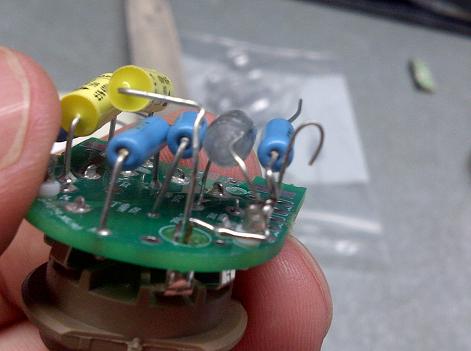

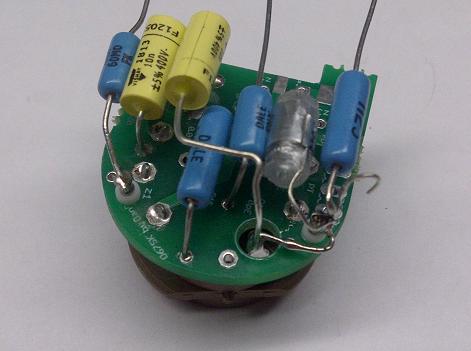

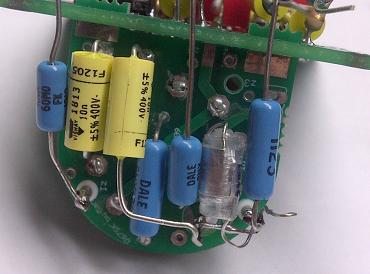

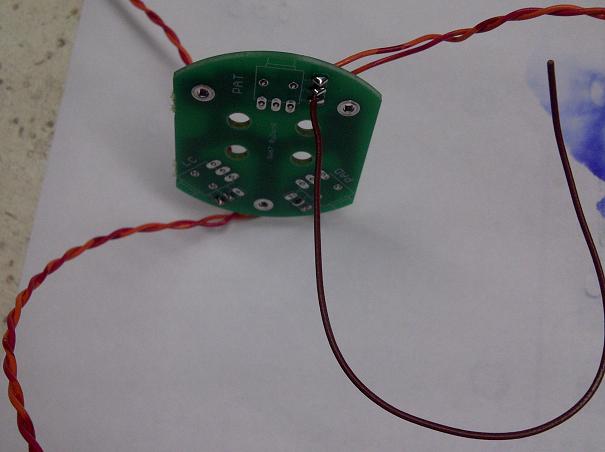

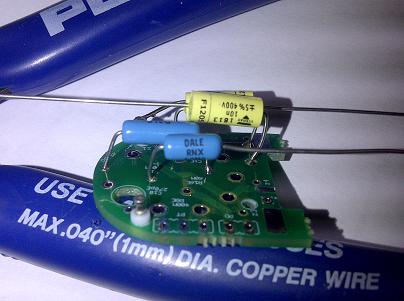

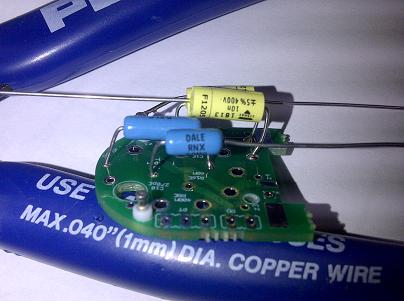

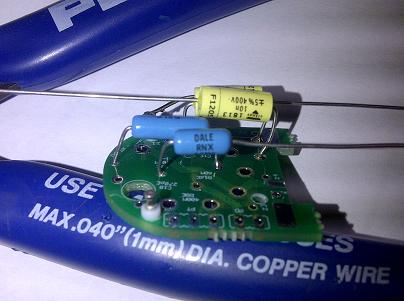

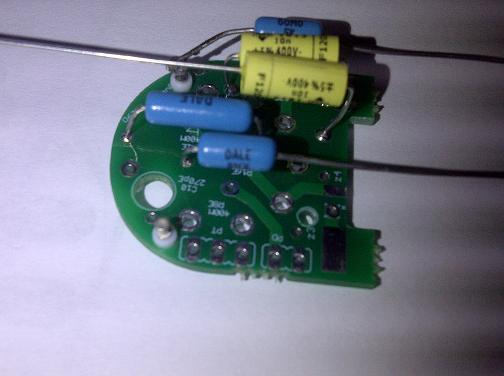

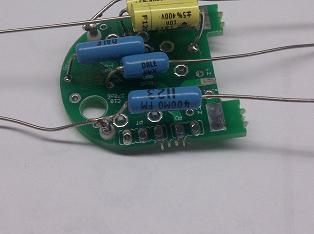

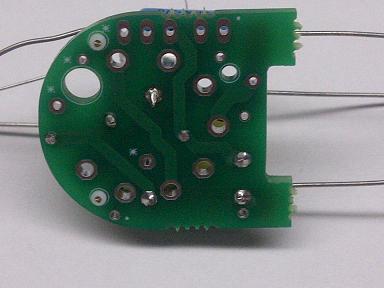

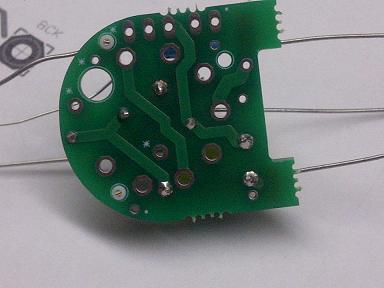

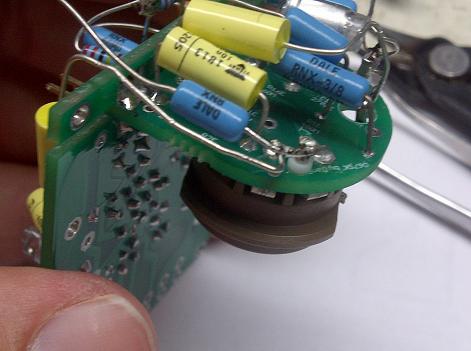

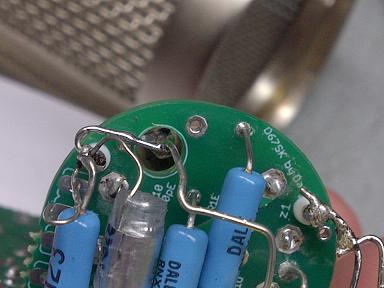

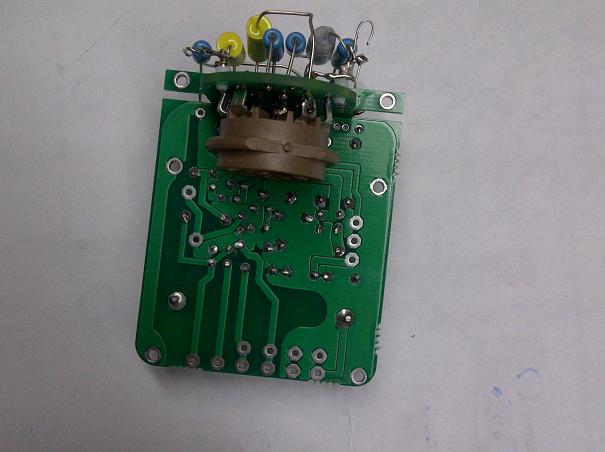

AMI or External Board Mounting Hints and clearance railing test,

and Yes this is My favourite Celebration beers the Boddingtons ;D

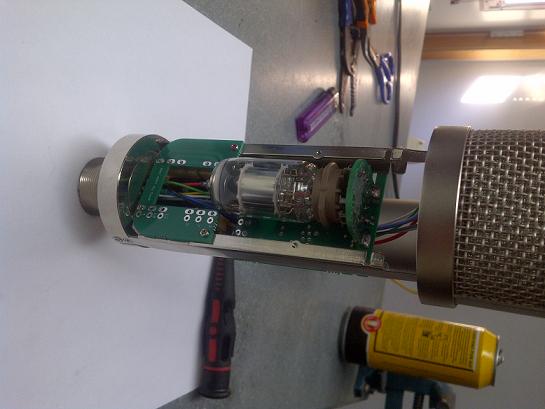

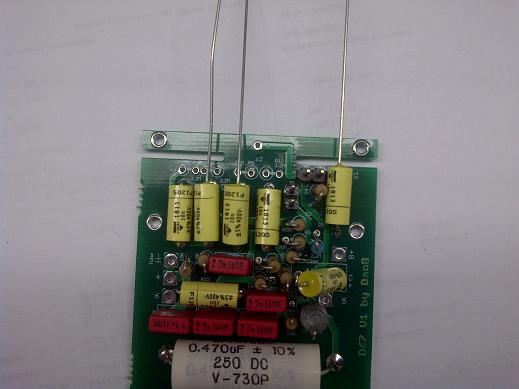

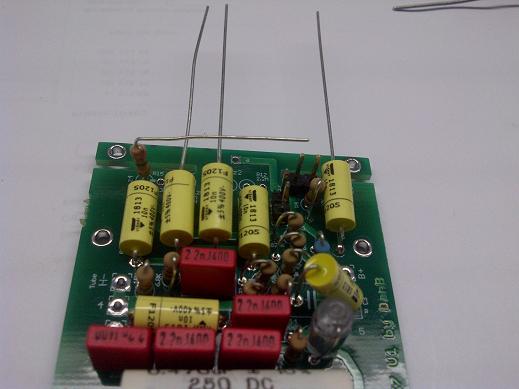

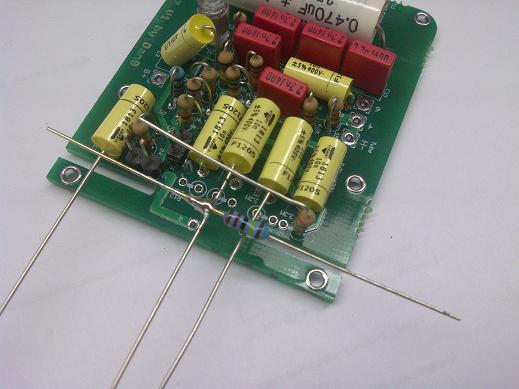

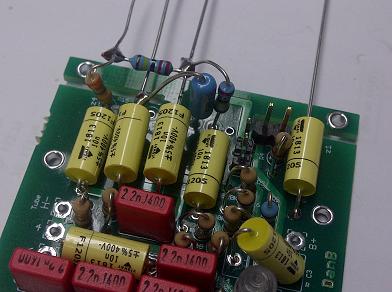

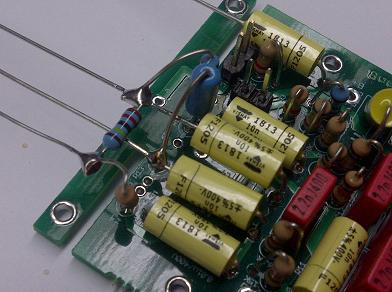

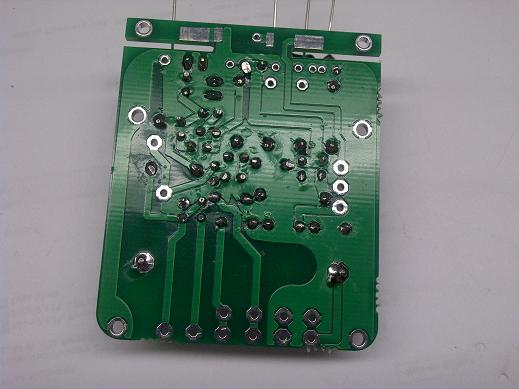

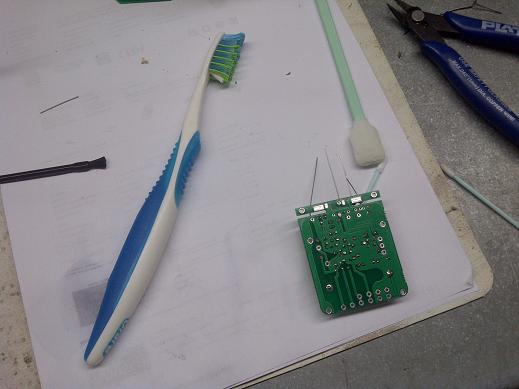

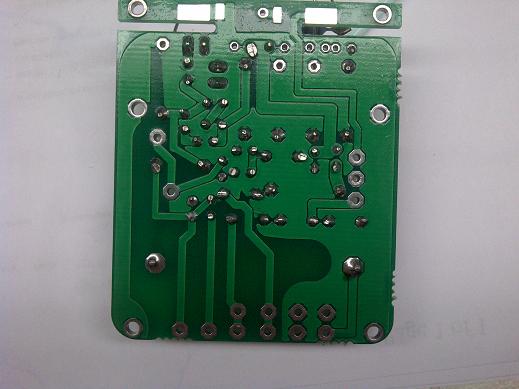

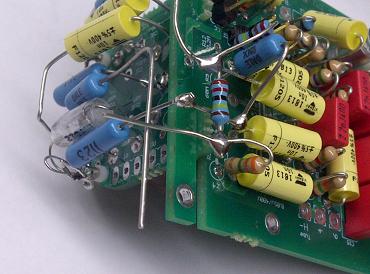

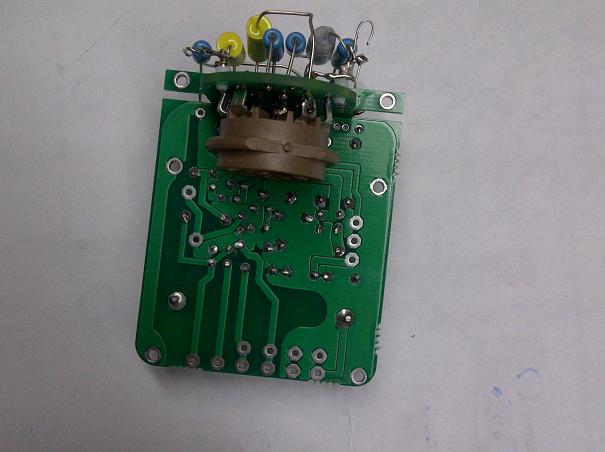

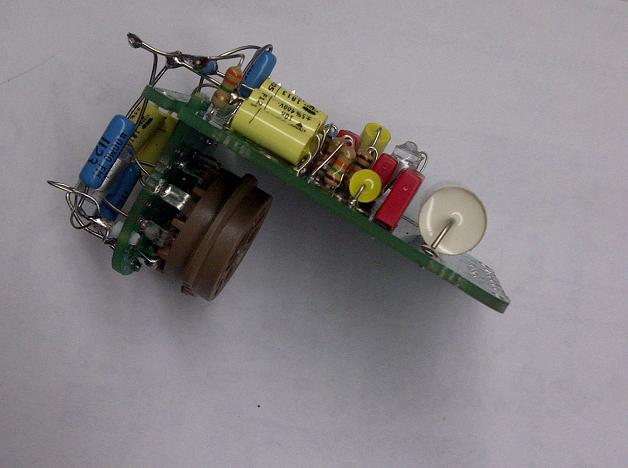

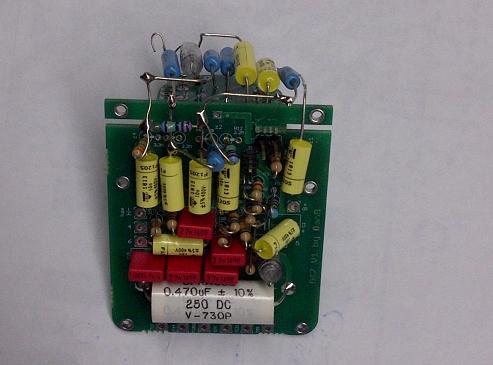

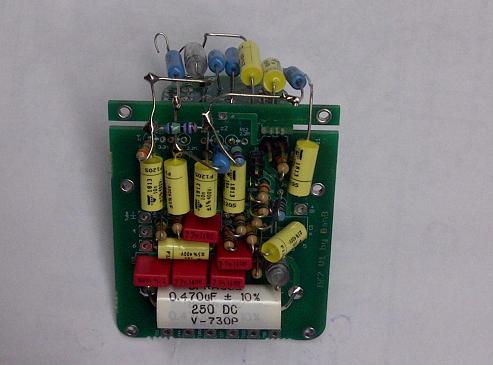

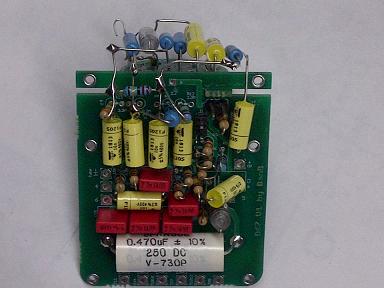

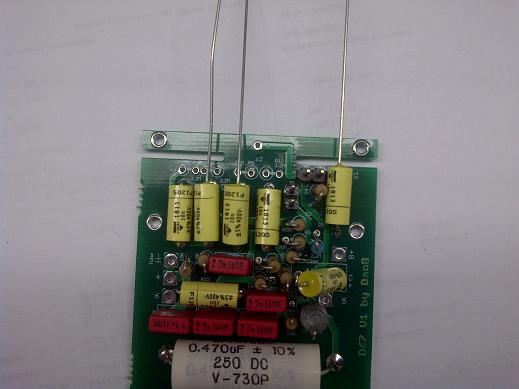

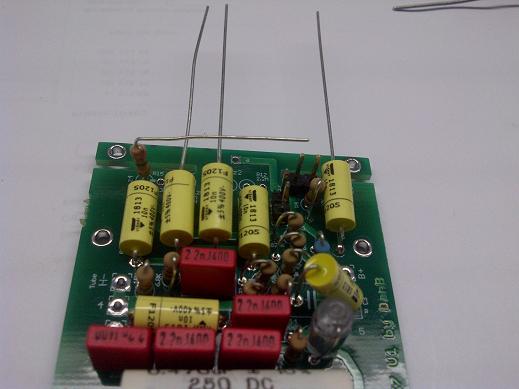

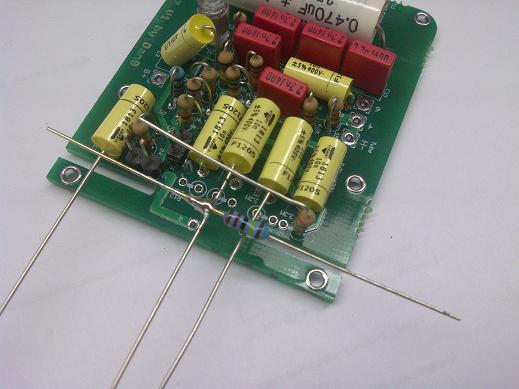

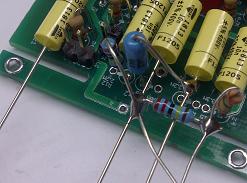

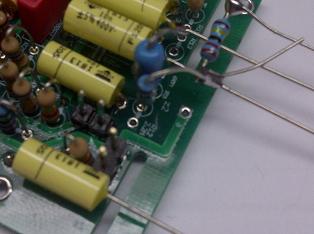

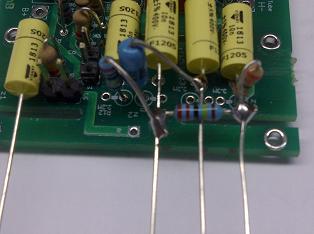

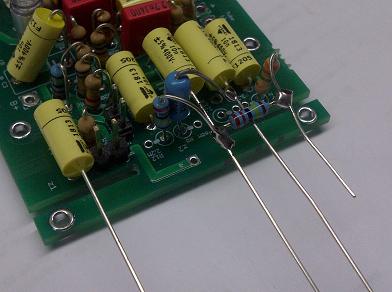

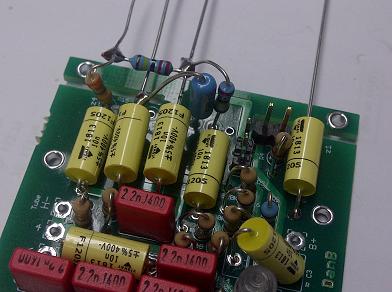

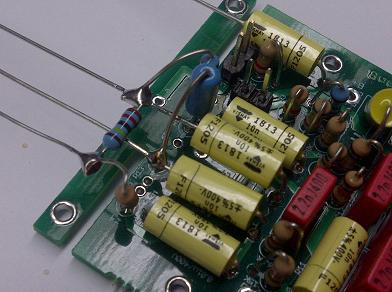

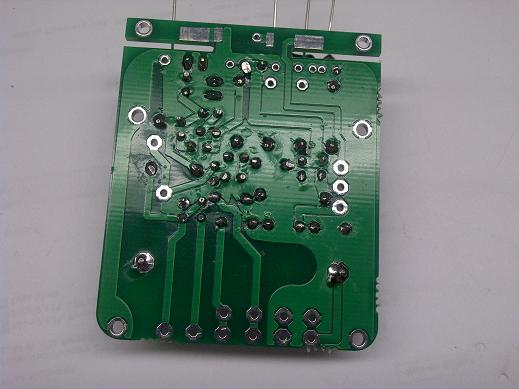

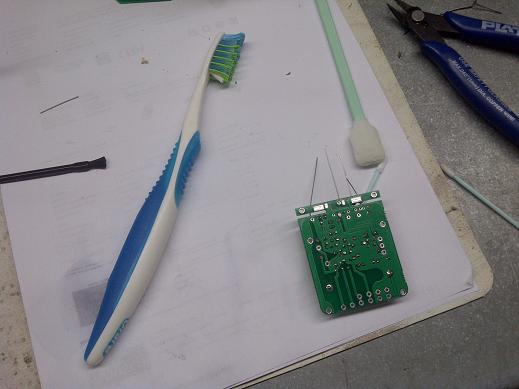

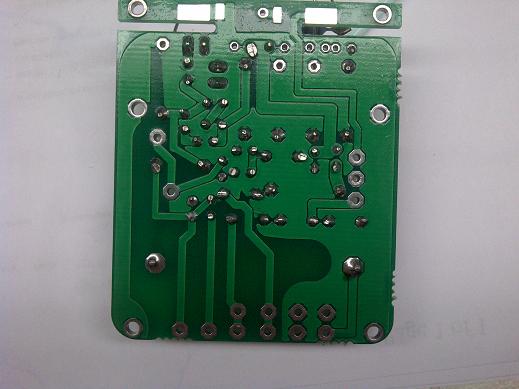

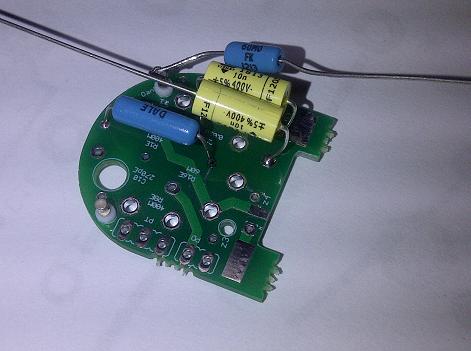

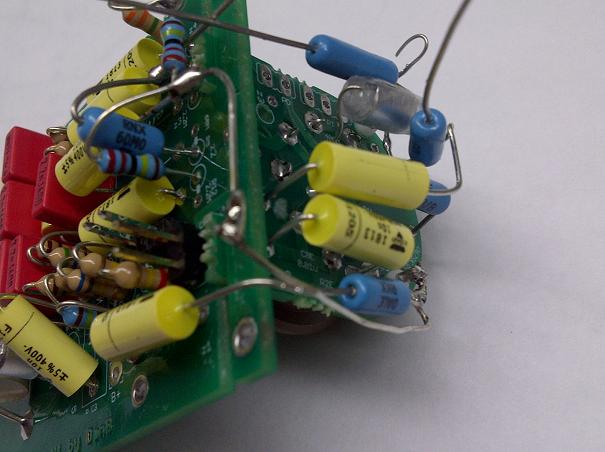

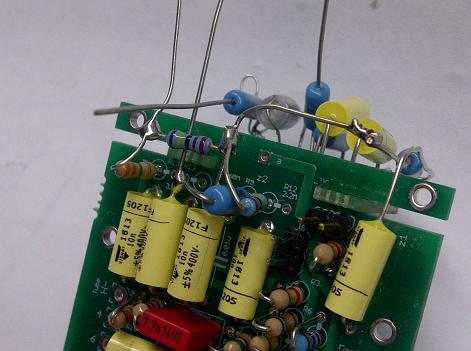

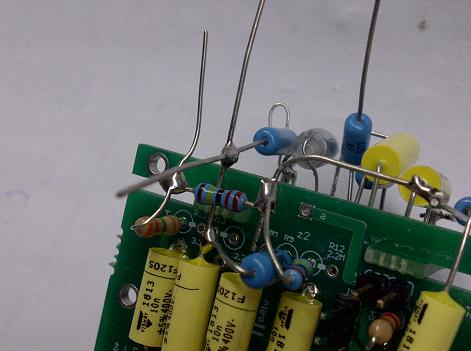

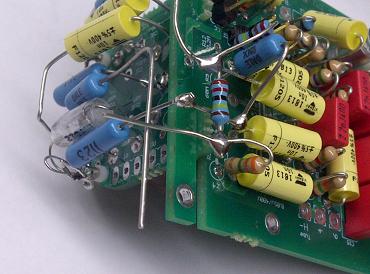

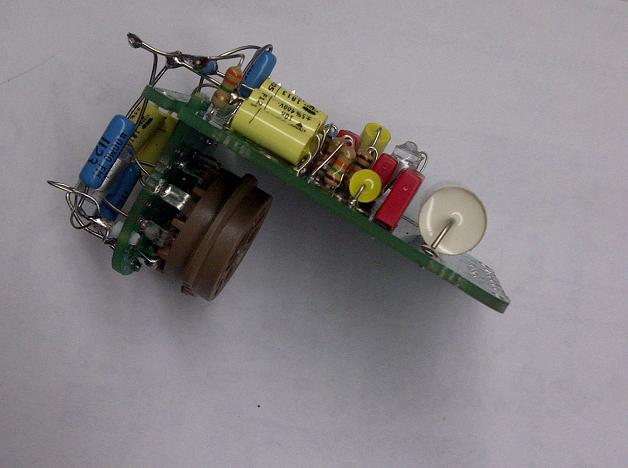

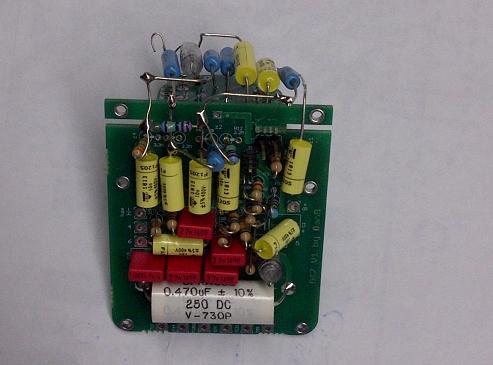

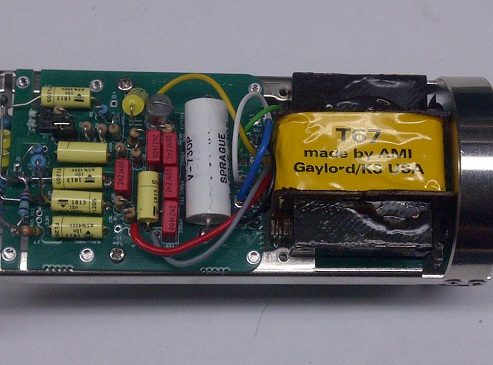

The D-U67 Build

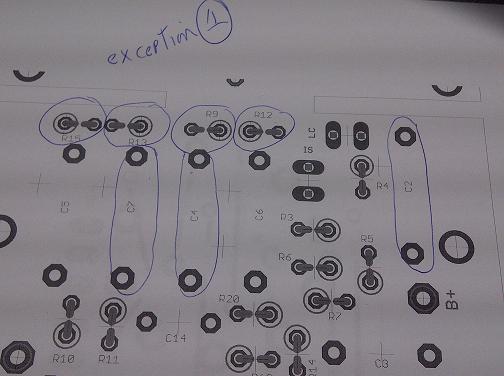

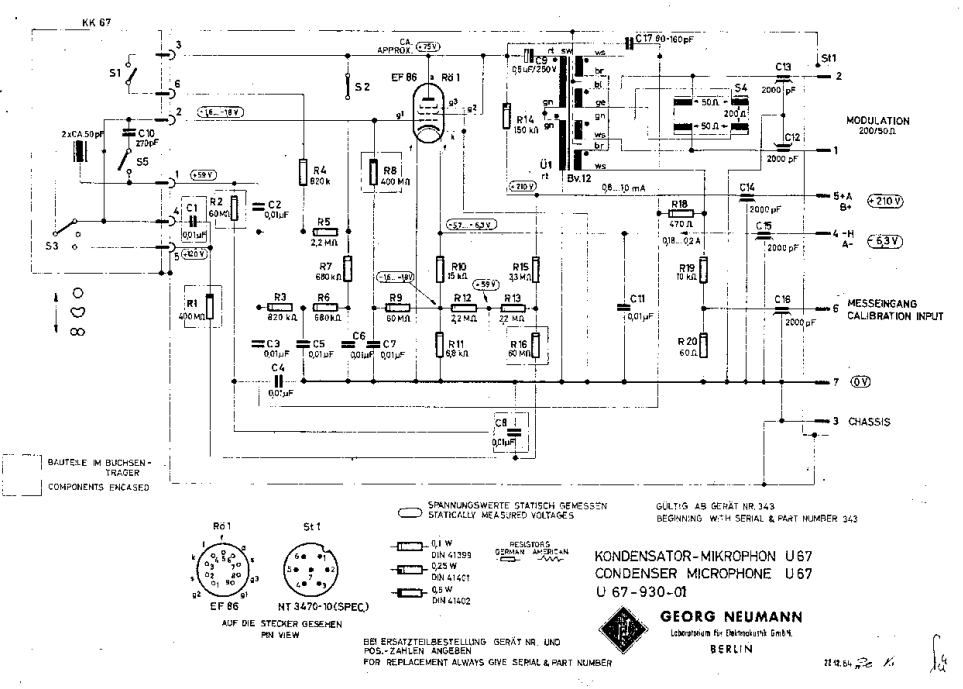

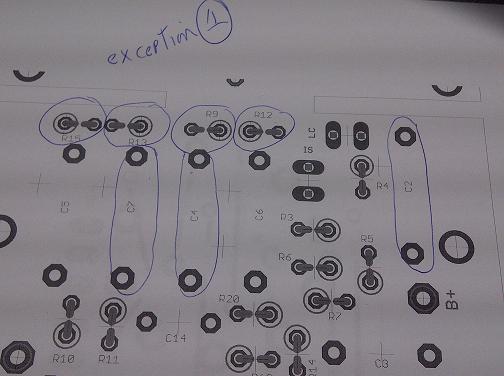

All Of it, 100% original Circuit , No Exception Include Calibration Check Port & Internal LC shift Switch

Include Calibration Check Port & Internal LC shift Switch

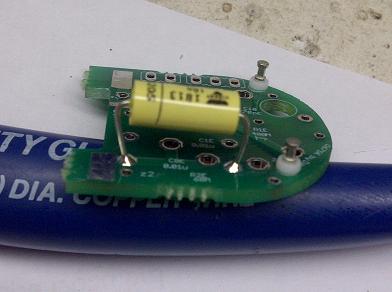

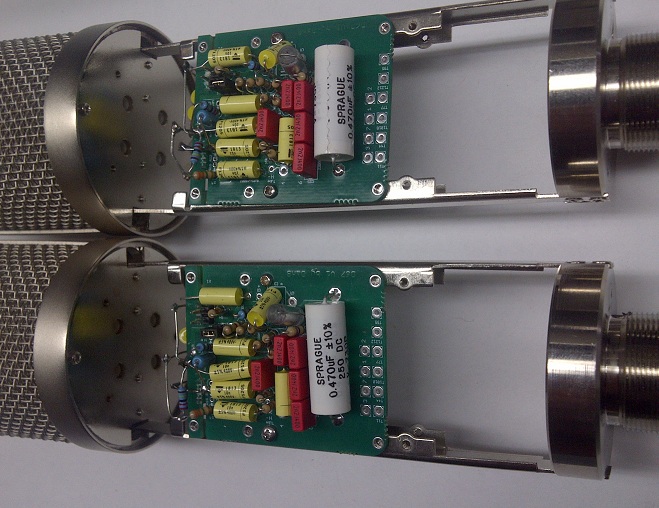

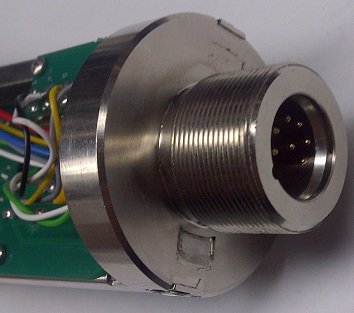

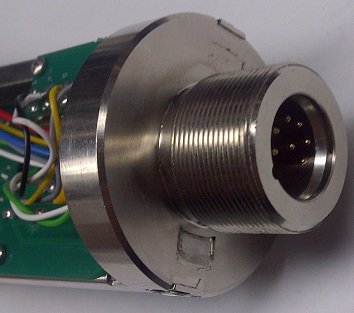

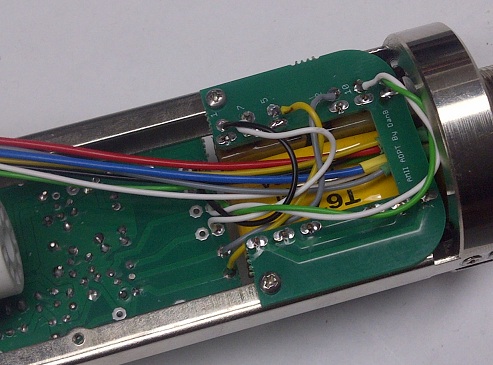

External Transformer Such As Tabfunkenwork AMI T67 PCB shown in Photo Build , Ioaudio BV 12 on the left,

PSU thanks To DanDeurloo

Dan's Case Available here : http://www.collectivecases.com/

or Here: http://www.groupdiy.com/index.php?topic=41963.0

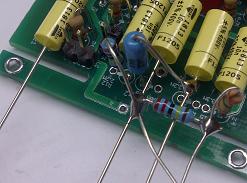

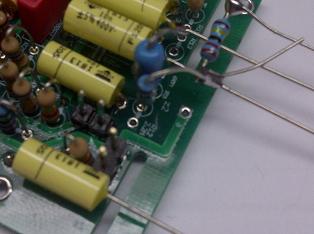

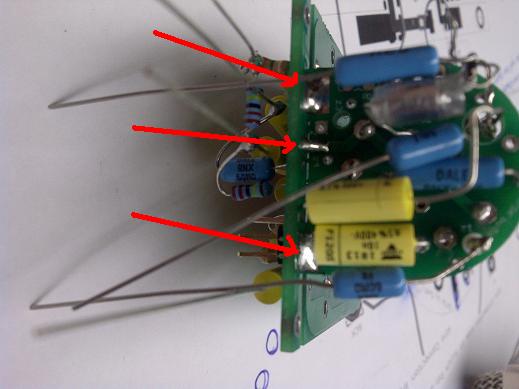

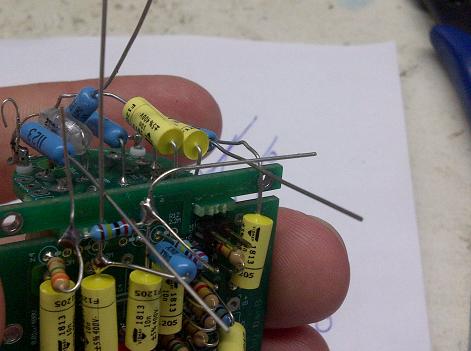

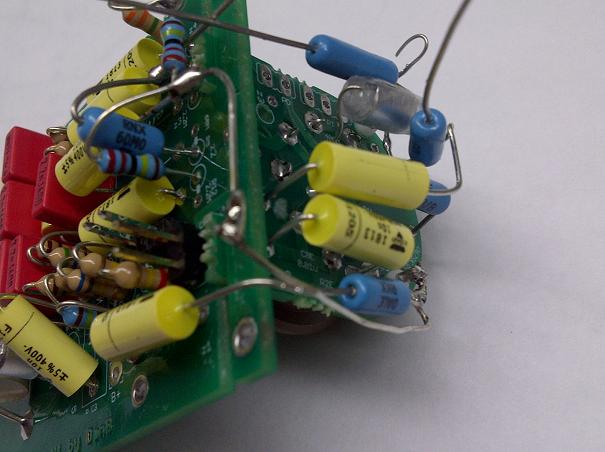

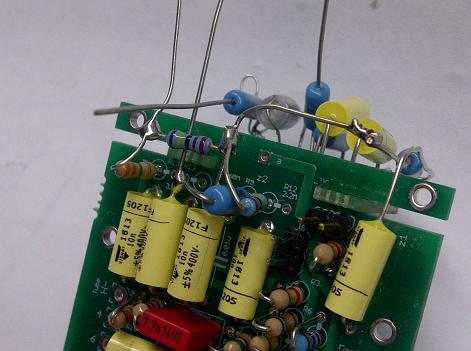

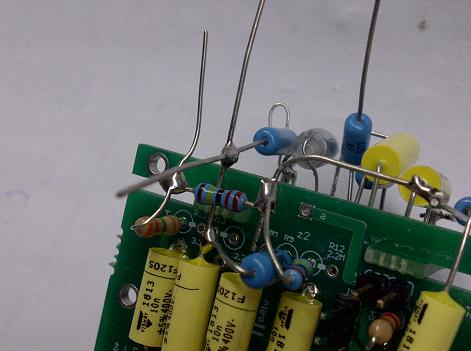

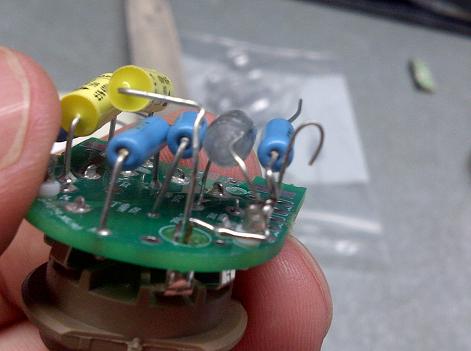

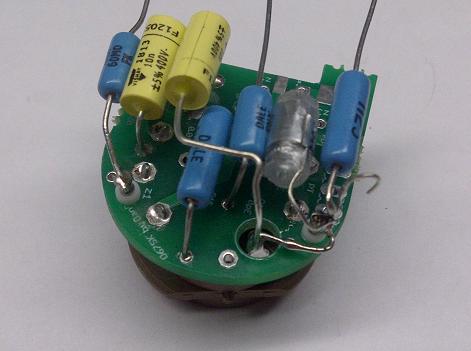

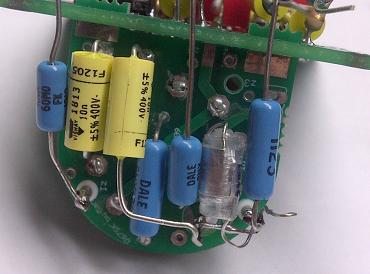

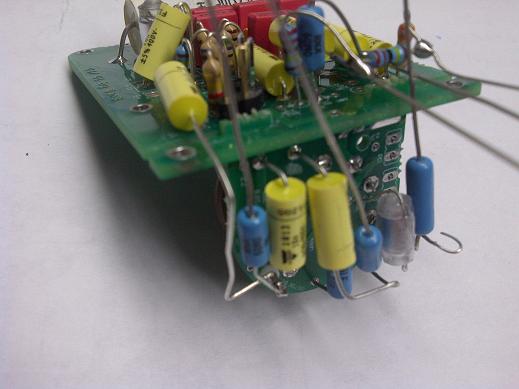

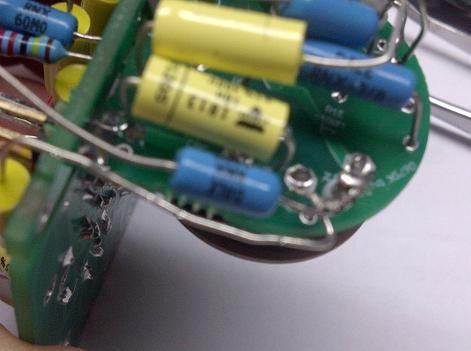

The Build of the HZ floating Bridge uses all the existing resistor and capacitor leads

The D-U67 and the D-M269 Share the same pattern switch , low cut switch, and pad switch wiring. the only difference is for Pattern Swich Pin 1 For A complete switch connection tutorial see here in build Part 2 : http://www.groupdiy.com/index.php?topic=51350.0

AMI T67 Example.

Let's get those Electron flowing.

All of the info: http://www.groupdiy.com/index.php?topic=49675.0

The D-U67 Tube Mic

Mic Assembly Tutorial

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a0351f.pdf

PSU Assembly and Tips

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a03549.pdf

http:// Check this First: Project Files for The D-U67 Build

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a0356c.zip

The Safety Manual and Considerations.

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a0357d.pdf

IMPORTANT:

You Should always have the SHLF Jumper in position in the PSU PCB , this will ensure that your cable shield is tied at both end of the cable and connect to 0V

you Should Also have the 0V star grounded to your case and then from there to you IEC earth ground ,

For More Information on Grounding

https://www.dropbox.com/s/6y121dasm3iw4ba/Sound_System_Interconnection.pdf?dl=0

Best,

Dan,

D-U67 Mic Parts: http://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=83ad963d23

Note: BOM include 56R For R20

D-U67 PSU Parts : http://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=b5c122b4d0

Note: BOM include 560R for R9

OK , here is the briefing

For More Information on Grounding

https://www.dropbox.com/s/6y121dasm3iw4ba/Sound_System_Interconnection.pdf?dl=0

i always have the habit of never float 0V on a PSU i always star ground it to the chassis and then IEC plug ,

about the shield it is imperative at all time that the shield has a path to the chassis as well so it will protect YOU and Your investment. in the mic PCB the shield and 0v are on the same level meaning they are connected togheter and the mouting hole of the pcb are connected to the chassis , this lead to always have the shield protecting you because i ALWAYS star Ground 0V to the power supply case so in all everything always goes to the earth no matter what , So in essence this SHLF is somthing i wanted to implement as a ground lift but it was not done properly and i am glad it turned that way because it is safe this way ,

i guess i am an habit person i always did it like this and never had any problem.

if you have hum problem you can start floating thing arroundb like the 0V from PSU to in respect to Chassis or the shield but it is very something of last resort and i dont recommend it as it is to me potentially unsafe to do so ,

Hope this helps, above is a good read about how to properly ground the equipment togheter,

best,

Dan,

Important Note

Update on PSU Power Specification

Problem : R2 is getting way too hot

it has been brought to my attention that the PSU Power Supply (R2) Power was out of tolerance and heating passed its

ratings. this has been very isolated case only.

Do Not Use More than 6VA for the 20V transformer

Explanation: the Hammond transformer in the BOM was specified at 300ma 6VA , some DIYER used higher power supply rating cause a bigger Voltage drop in R2 than anticipated supplying more current to it causing the resistor to get too hot and melt the solder on the pcb. those who have used the Specified Hammond transformer can go ahead and only upgrade R2 for the new higher power resistor if needed. Those who have the old hammond transformer should be ok as it cannot outpout enough power to go past 2W specified, only a resistor upgrade is need in this case.

Solution: After Analysis of the power dissipation required on R2 to provide with the Heater Voltage. it has been found that

new higher power R2 Resistor 22ohm 5W to alleviate this as well and it will run cooler. it is also recommended that R2 and the Zener diode shall be lifted a little bit from the PCB to permit better heat disspipation to run even cooler :[/b]

Now Included in the BOM

Here is the 2 suggested part for R2 5Watt as well updated in the BOM

http://ca.mouser.com/Search/ProductDetail.aspx?R=RWHSE09TU025R0FSvirtualkey58440000virtualkey605-RWHSE09TU025R0FS

or

http://ca.mouser.com/Search/ProductDetail.aspx?R=AC05000002209JAC00virtualkey59420000virtualkey594-AC05W22R00J

Many Thanks To TLRT for catching those potential issues.

Best,

Dan,

The only 2 parts that is not (Europe 230V) compatible is the hammond 20VAC and the PSU pilot Lamp wich is 120V everything else is fine except the fuse will need to be 0.1A instead of a 0.2A for north America, you will need a minimun 6VA traffo for the filament side,

alternative part number are discussed in this thread here :

http://www.groupdiy.com/index.php?topic=49675.20

http://www.groupdiy.com/index.php?topic=49675.40

PSU Schematic

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a0358d.pdf

Errata Feedback winding polarity http://groupdiy.com/index.php?topic=50021.800 reply # 814

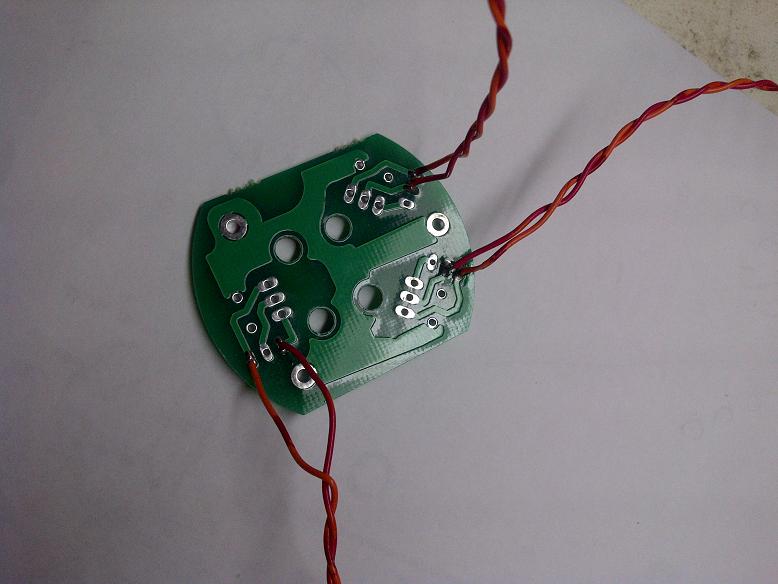

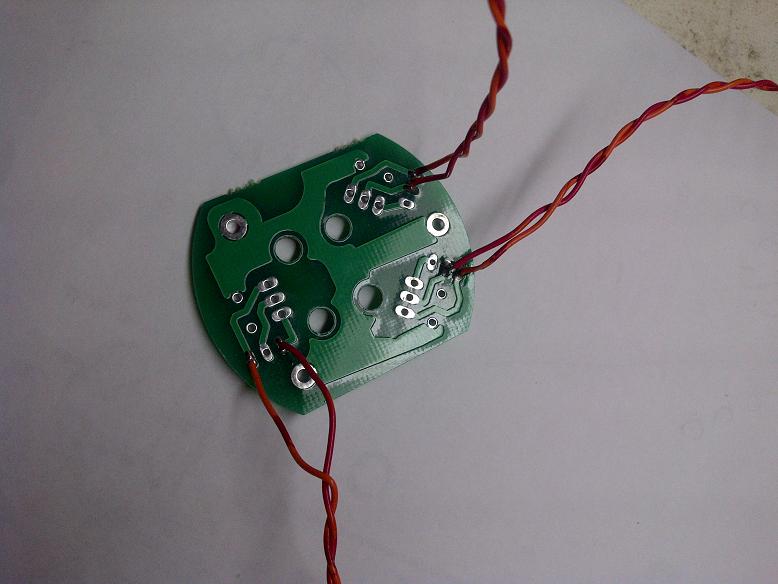

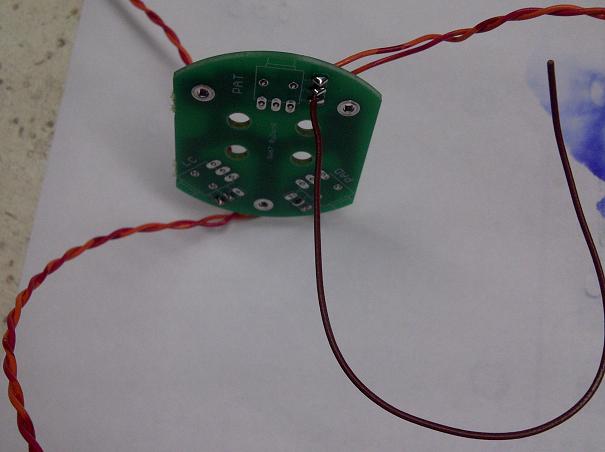

AMI T67 Corrected Wiring to main microphone pcb

From transformer board to mic PCB

Pad 5 -----> mic pcb pad T1212

Pad 12 -------> mic pcb pad T55

Pad 1 --------> mic pcb pad T44

Pad 4 --------> mic pcb pad T11

Pad 7 --------> mic pcb pad T1010

Pad 10 ------> mic pcb Pad T77

rjuly said:Here is the correspondance on the pcb pad for the U67 Mic pcb

AMI sent me the updated schematic with these details below.

The circuit:

... and the reference image:

Best,

Rich

yes i got it this morning , cant wait to start a new build with this traffo. i really like my D-EF47 with the BV8 classic series.

let get this bv12 classic series going

the 2 black wire are actually shiedling of the core, take those 2 wires to a gnd pad onm the pcb,

Also note that the Blue wire (4) is the +audio out and the White (3) is - audio out

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a035c5.pdf

best,

Dan.

See here for complete relationship between pad and transfomer on the AMI mic pcb,

http://groupdiy.com/index.php?topic=50021.msg720336#msg720336

BOM Annexe

https://cdn.groupbuilder.com/groupdiy/u/39511/58d1402a035d6.doc

Not inclued in the Mouser Bom are:

- Switches for Switch board.

- 1X 270pf Styroflex/630V

- 1X FeedBack Cap (80-160pf) styroflex/630V

Styroflex Capacitor Available Here :http://dl.dropbox.com/u/43869772/U67/Picture%20Tron/orderformDU67.xls

Microphone Body and accessories Available Here :http://www.groupdiy.com/index.php?topic=50015.0

Bellow Basic Setup for Different Version , different folks different strokes 8)

I have been working on validating the last details regarding mouting the AMI boards and last fine tuning regarding the Clearance of the track pad in respect to th railing and position, fit in the mic boady and hole tolerance , I am pleased to annonce that all my concerns on this have been validated ,

here some

AMI or External Board Mounting Hints and clearance railing test,

and Yes this is My favourite Celebration beers the Boddingtons ;D

The D-U67 Build

All Of it, 100% original Circuit , No Exception

External Transformer Such As Tabfunkenwork AMI T67 PCB shown in Photo Build , Ioaudio BV 12 on the left,

PSU thanks To DanDeurloo

Dan's Case Available here : http://www.collectivecases.com/

or Here: http://www.groupdiy.com/index.php?topic=41963.0

The Build of the HZ floating Bridge uses all the existing resistor and capacitor leads

The D-U67 and the D-M269 Share the same pattern switch , low cut switch, and pad switch wiring. the only difference is for Pattern Swich Pin 1 For A complete switch connection tutorial see here in build Part 2 : http://www.groupdiy.com/index.php?topic=51350.0

AMI T67 Example.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)