Bo Deadly

Well-known member

I'm looking at panel controls and trying to figure out what to use based on availability and what will work in my vertical mount system. This has always been a huge problem for me. I'm building one-off projects just for kicks. I don't sell boards or anything like that. This is strictly a hobby.

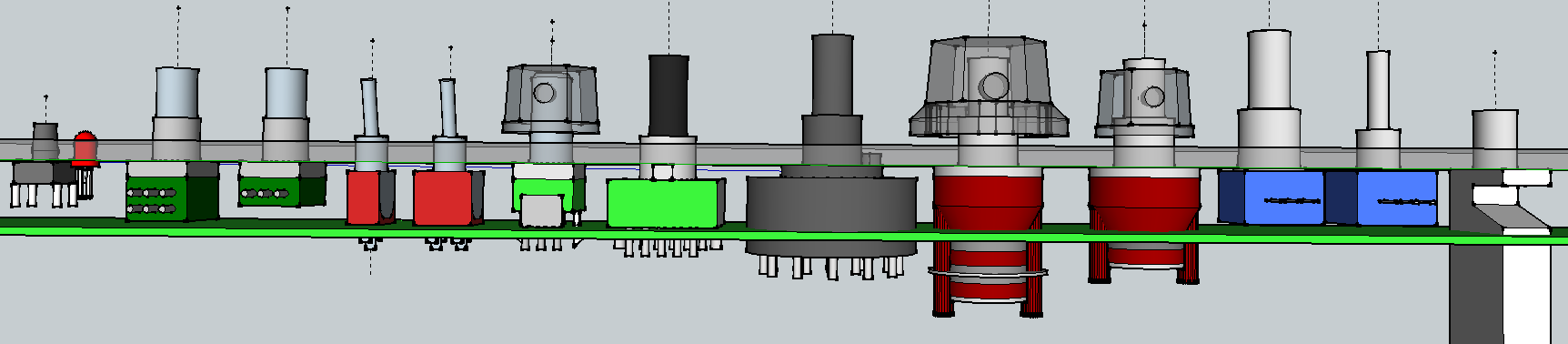

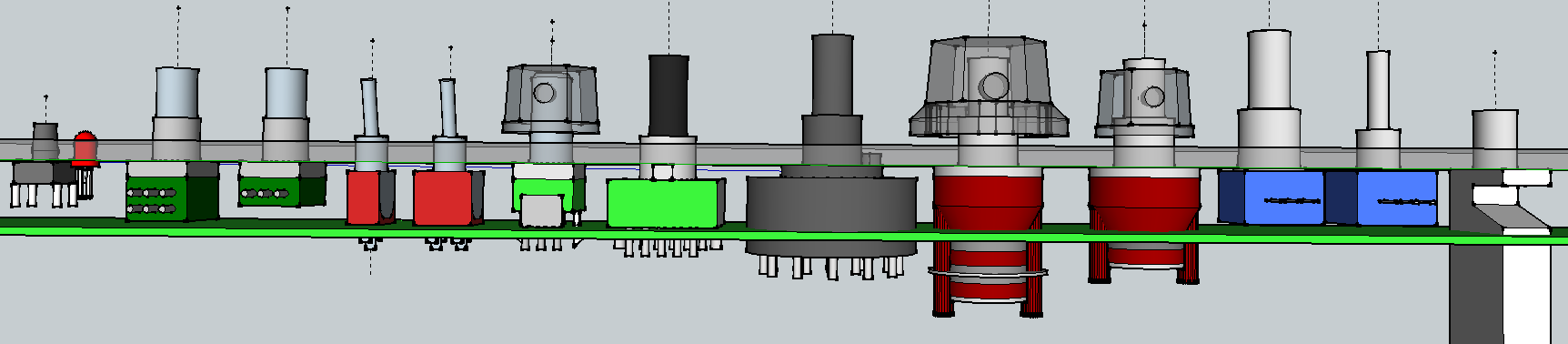

I have modeled various common panel controls in Sketchup. From left to right you have an SMD momentary button, 2mm LED, Alps 9mm, sub-mini toggles, Alpha 9mm vertical, Alpha R17 rotary switch, Lorlin rotary, Grayhill 71BD30 rotary, Bourns 51AAA and at the end is a Bantam TT jack. This is not an actual unit, it's just supposed to show the relative positions of bushings and such. These are accurate models created from datasheets and from measurements made with a micrometer:

The translucent grey is the 3 mm aluminum panel and the green is PCB.

So the general idea is that the Alpha 9mm vertical pot would be used wherever possible. This defines a 10mm gap between the panel and the first PCB (each module is a stack of PCBs connected with standoffs extending back from the panel). The toggles fit well, I can use right angle 9mm w/ adapters and I could make holes for somethings if necessary. Most modules have LEDs (at least 1, probably 2, some have 10) and momentary buttons that need to be mounted close to the panel so really big controls like the Lorlin switches are not going to work.

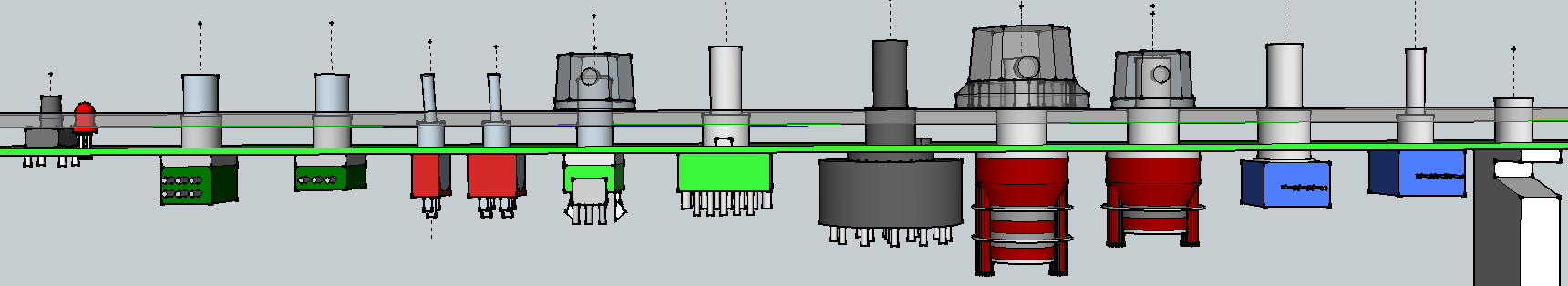

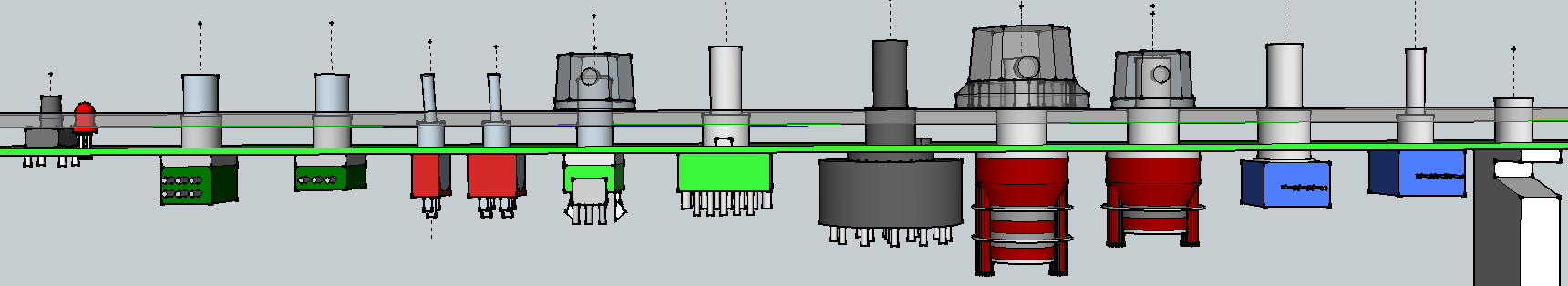

So, my first question is, in general, does anyone have recommendations for improving this scheme? I have been flip flopping between the above scheme OR mounting the controls on the PCBs and not the panel like this:

But I am concerned about structural integrity. And unfortunately it looks like 15mm long shafts are starting to dominate and they just don't reach through the 1.2mm PCB + ~3.9mm gap + 2.5mm panel and still grab the set screw of even the smallest knob.

Another question is, what do you think of the Alpha SR1712F rotary switch? It is highly available and comes in 2 pole 4 pos and 1 pole 8 pos. It could be used a LOT in a vertical mount system like this. It's rated 16V DC 0.3A so I think it should be able to handle 32V AC 0.15A no problem right?

Can anyone recommend parts that I should look at? I have a lot of momentary buttons and LEDs so if I use the 10mm space, I need to find a different momentary button (maybe with builtin LED).

I have modeled various common panel controls in Sketchup. From left to right you have an SMD momentary button, 2mm LED, Alps 9mm, sub-mini toggles, Alpha 9mm vertical, Alpha R17 rotary switch, Lorlin rotary, Grayhill 71BD30 rotary, Bourns 51AAA and at the end is a Bantam TT jack. This is not an actual unit, it's just supposed to show the relative positions of bushings and such. These are accurate models created from datasheets and from measurements made with a micrometer:

The translucent grey is the 3 mm aluminum panel and the green is PCB.

So the general idea is that the Alpha 9mm vertical pot would be used wherever possible. This defines a 10mm gap between the panel and the first PCB (each module is a stack of PCBs connected with standoffs extending back from the panel). The toggles fit well, I can use right angle 9mm w/ adapters and I could make holes for somethings if necessary. Most modules have LEDs (at least 1, probably 2, some have 10) and momentary buttons that need to be mounted close to the panel so really big controls like the Lorlin switches are not going to work.

So, my first question is, in general, does anyone have recommendations for improving this scheme? I have been flip flopping between the above scheme OR mounting the controls on the PCBs and not the panel like this:

But I am concerned about structural integrity. And unfortunately it looks like 15mm long shafts are starting to dominate and they just don't reach through the 1.2mm PCB + ~3.9mm gap + 2.5mm panel and still grab the set screw of even the smallest knob.

Another question is, what do you think of the Alpha SR1712F rotary switch? It is highly available and comes in 2 pole 4 pos and 1 pole 8 pos. It could be used a LOT in a vertical mount system like this. It's rated 16V DC 0.3A so I think it should be able to handle 32V AC 0.15A no problem right?

Can anyone recommend parts that I should look at? I have a lot of momentary buttons and LEDs so if I use the 10mm space, I need to find a different momentary button (maybe with builtin LED).