Alright, got your mail, fantastic!

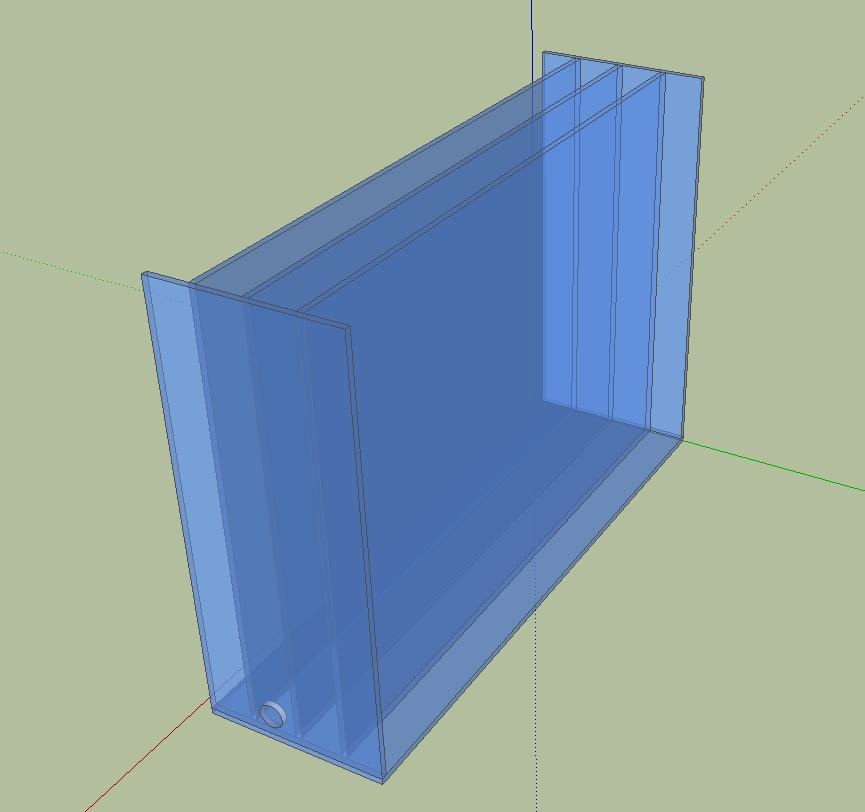

I took the liberty of uploading your sketch to the server:

That's exactly the way mine looks.

Regarding your questions:

What type of glass to use - I've never used Sekurit or Securex glass, that's the stuff that gets

used for car windows, right? You mentioned them saying floatglass was the right kind, if I get

it right then float was the standard kind for windows, in which case you're probably talking about

the same kind I have here in my workshop. Regarding thickness, 5mm gave me the ideal stability

and didn't need to be more but you can of course get thicker if you're inclined to.

The extra at the edges is a trick I got from the commercial plastic units, like you mentioned in

your email it works wonders to give the thing extra stand and really makes for a stable unit

in general.

You gave it a hole on the bottom for attaching an ABS faucet - if you wish, go right ahead and

install one, this can either be cut by the guys who prepare the glass for you or you can do it

yourself with a Dremel and an engraver, if you do do it yourself be sure to get some cooling

spray and cool it while you're cutting or you can break the whole thing.

Personally, I don't have any faucets because the way it worked for me was to get myself a ca.

1.5m plastic hose that fit down in there to use as a siphon. You can fill the hose with water

holding it shut at both ends, then plunge one end down into the acid holding the other end

shut, and then just stick the other end into a 5L plastic canister and let go.

Here is a picture of my etchery with the machine (before I had the other pumps and the wood

aerators/diffusers):

While I had originally gotten the big aquarium because I wanted to build myself a spray etching

machine - which turned out to be not only a bit complicated but also would have needed a much

bigger aquarium to start from for the sizes I do, I simply used the big aquarium as an emergency

collection tank in case anything should break while I'm working.

Another good reason to use a big aquarium is this: When you are etching and especially once

you have the microbubbles, this thing will tend to atomize a lot of little droplets of acid into the

air - which can really give you a headache the next day the way Stolichnaya can't (at least I

think I remember that being one of the reasons). So in the aquarium, when I'm etching, I

use those big grey lids you see on the right to cover the whole thing up so that the air is fit to

breathe

To hold the PCBs in place, btw (which is why the big aquarium should be large enough to accomodate)

at this size I discovered something waaaaaay better than these plastic frame-style PCB holders.

You get yourself a cheap version Haemostat like they use in the hospital to clamp stuff. This

you can attach to your PCB and then just hang it in there.

So if you do get a good aquarium, make sure you have enough space toward the top to be

able to get the lid on properly and still everything fits

Regarding Signolit SL-Z:

This can be optional at the beginning, depending on your laser printer you can very well use standard

transparent paper and get excellent results, though toner blackener works wonders. There should

be general transparent polyester printing medium available that is heat-stabilized, possibly consult

with someone who is at an architectural faculty or so, they need the stuff for their drawings.

The reason I use it is because it's much easier to get two prints that are completely identical and you

can lay on top of each other, thus making the print opaque. Getting a real seriously opaque print with

a laser printer can be a real fuss sometimes, because it doesn't deal well with areas of black - I have

the LaserJet5000N, but of course if you know of one that does even more and thicker toner by all

means let me know

This also goes a long way toward doing double sided PCBs, where you can essentially make an A4 sized

PCB with minimal distortion to both sides - I managed to get about 0.1mm/10cm, can't get much

more than that out of a laser I'm afraid.

The sickest thing, aside from a proper photoplotter (6000€+Agfa film and darkroom) is to get one

of those digital offset printers that are really wide and print directly on clear plastic film. They also

use toner, but their toner is more like a paste and so does the most incredible black you can get.

They also don't distort, it's amazing. You stick your images into one of those things and then lay

two on top of each other for double sided, you get 100% coverage of both of them. If I could get

my paws on one of those second hand that would be awesome.

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)