tommypiper

Well-known member

API said:Of course i had to do a fancy nameplate for these extra inputs....

Awesome thread. How do you make those nameplates? Are they plastic or metal? Do you have a machine for them?

API said:Of course i had to do a fancy nameplate for these extra inputs....

When I started doing electronics you could buy lots of typefaces from Letraset, and make your own labels.API said:mjrippe, i totally hear you and agree.

I have been thinking alot about this as well but have not yet figured out a way to add the numbers in a nice and pleasant way yet.

I actually thought about engraving the new VU covers with numbers, just like how the old ones were engraved.

Since i added the peaklead in the center under each VU it will not look good there and above the VU´s would look strange to my eyes as well.

But i agree, they would be handy.

API said:I have been looking for the old and correct material which is usually called Traffolyte

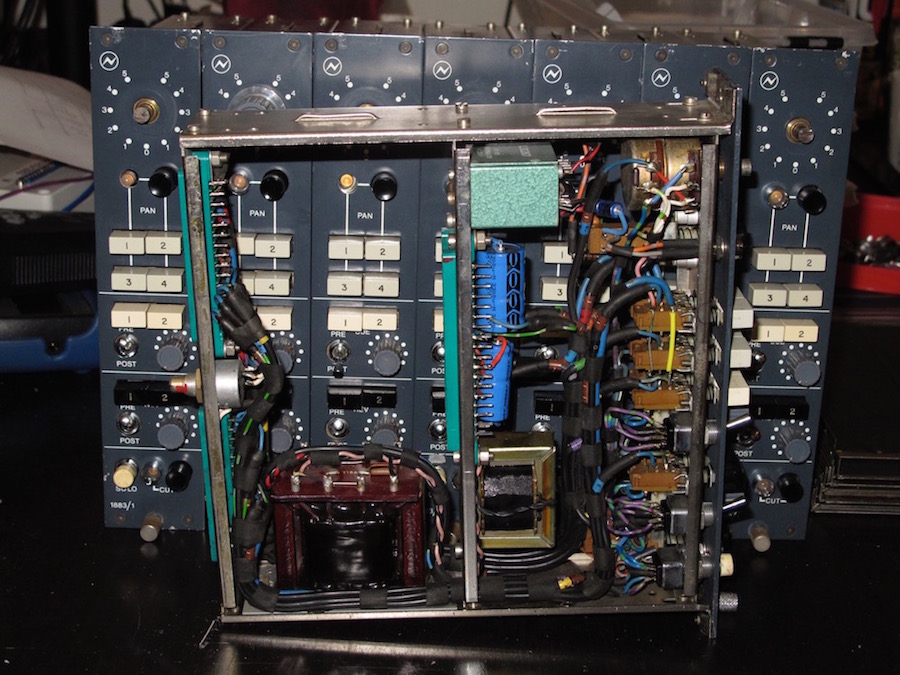

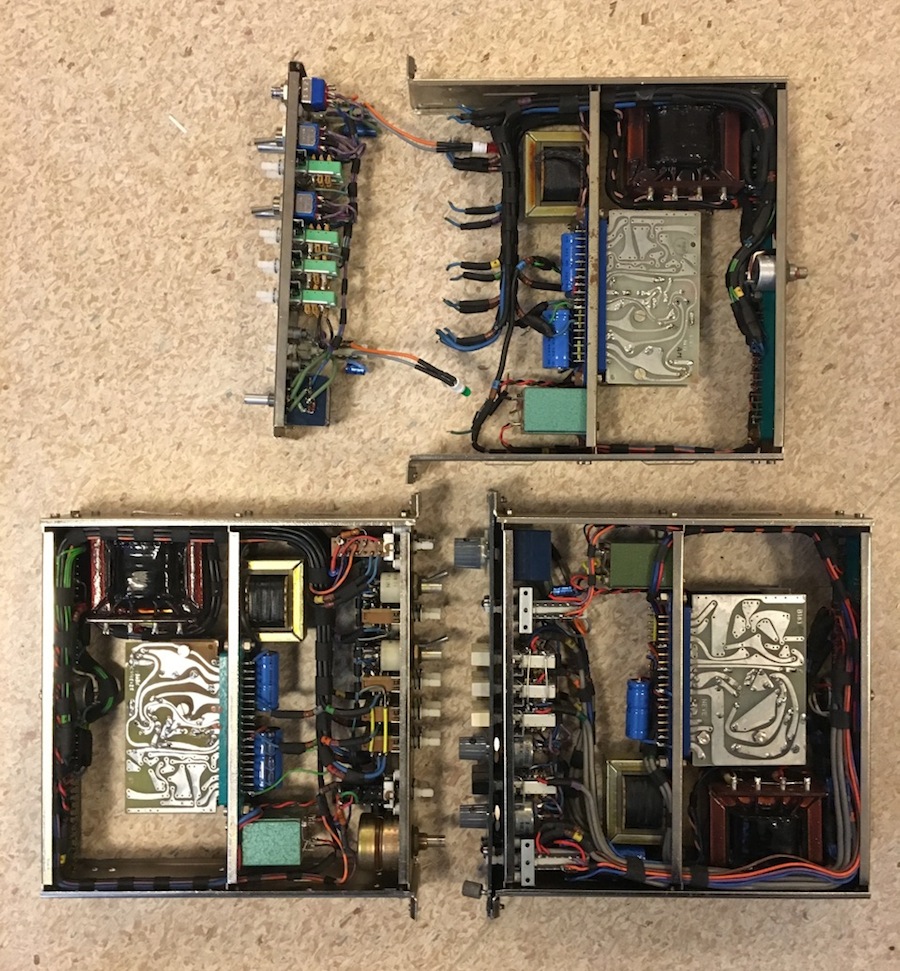

New owner???pvision said:The new owner is going to get a wonderfully hand-crafted, restored console

And a great story it was. I, for one, thank you for it.API said:So its time for the final chapeter of this now very looooooong story!