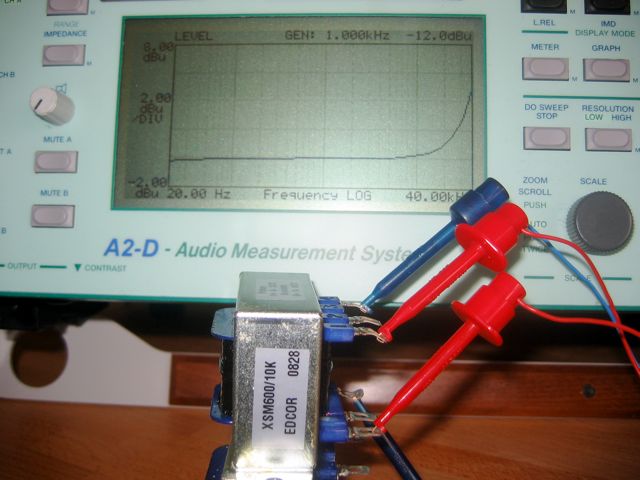

There seems to be a trend of this sort of roll-off in builds now and then, mainly LA-2A builds. Can't say I've noticed anyone trying another Edcor in the search for a fix.

Quality control: everyone should probably take the time to test all of their Edcors before using in any project. There are enough reports of mis-wired and open connections as shipped to warrant user scrutiny. Same would surely hold true for other issues. I know I couldn't wind transformers at that price and hope to offer real QC; only good customer service for problems as received. Edcor has been great about shipping out replacements in problem cases I've had. Not a 'thumbs down' comment at all, just a reality check on the real value of $10.

Maybe altogether unrelated to your problem; could be your card doesn't have enough drive for the load, but I doubt that.

Was I going to say something about filament supply earlier? No, I already said it. :razz:

Quality control: everyone should probably take the time to test all of their Edcors before using in any project. There are enough reports of mis-wired and open connections as shipped to warrant user scrutiny. Same would surely hold true for other issues. I know I couldn't wind transformers at that price and hope to offer real QC; only good customer service for problems as received. Edcor has been great about shipping out replacements in problem cases I've had. Not a 'thumbs down' comment at all, just a reality check on the real value of $10.

Maybe altogether unrelated to your problem; could be your card doesn't have enough drive for the load, but I doubt that.

Was I going to say something about filament supply earlier? No, I already said it. :razz: