Moses

Well-known member

Hi!

Im planning on putting together a VU/PPM meter, but I also want to include a crest factor meter in there.

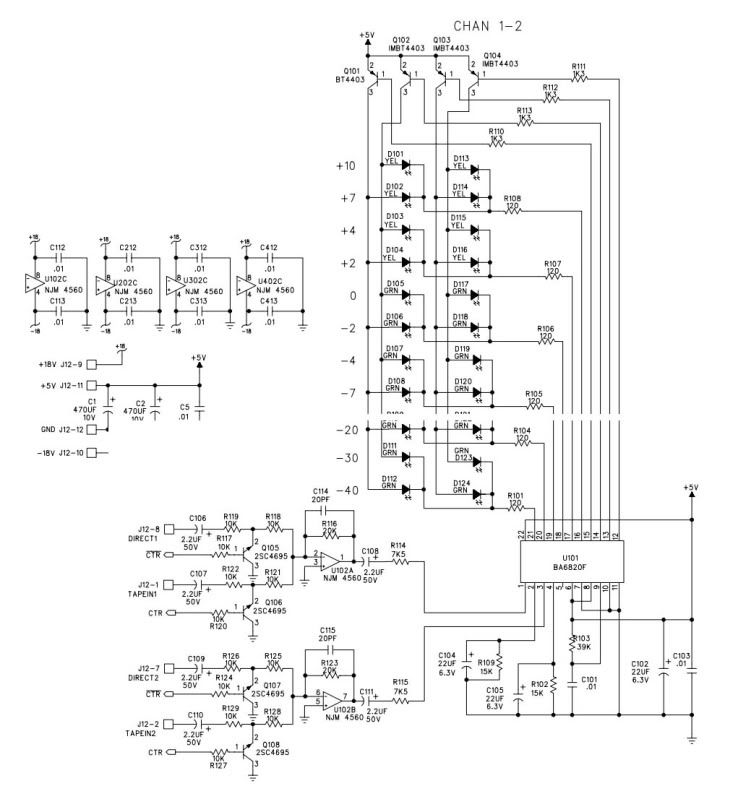

I'm thinking that I can basically copy this Calrec UA8000 meter schematic, and connect a differentiator at the outputs of the VU Filter and PPM Peak detector circuits in order to create the crest factor reading.

However, Im a little confused as to how the Law CCT (bottom left) works, and what it does...

Any help is much appreciated!

Thanks,

Mo

Im planning on putting together a VU/PPM meter, but I also want to include a crest factor meter in there.

I'm thinking that I can basically copy this Calrec UA8000 meter schematic, and connect a differentiator at the outputs of the VU Filter and PPM Peak detector circuits in order to create the crest factor reading.

However, Im a little confused as to how the Law CCT (bottom left) works, and what it does...

Any help is much appreciated!

Thanks,

Mo