culteousness1

Well-known member

Hi Team,

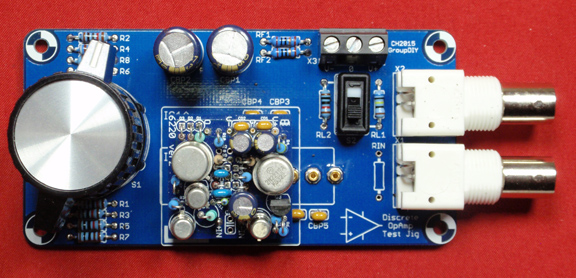

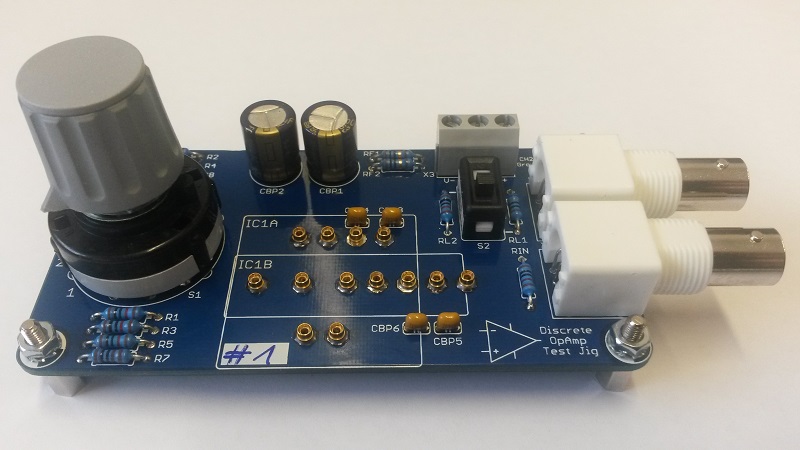

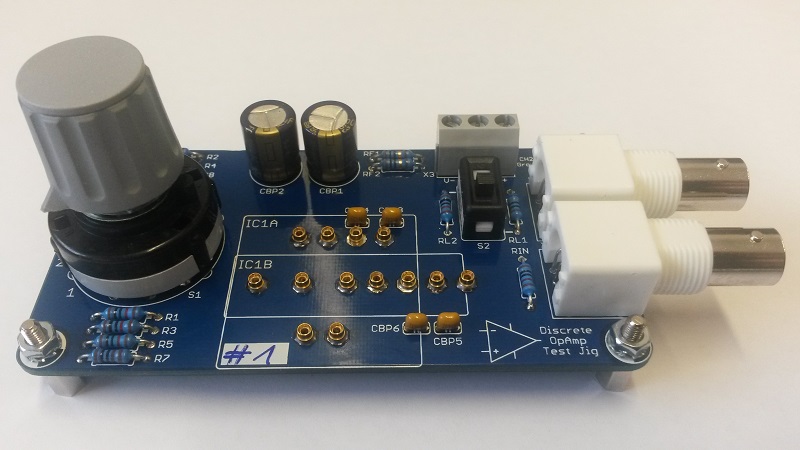

I just wanted to share my DOA Test Jig with you:

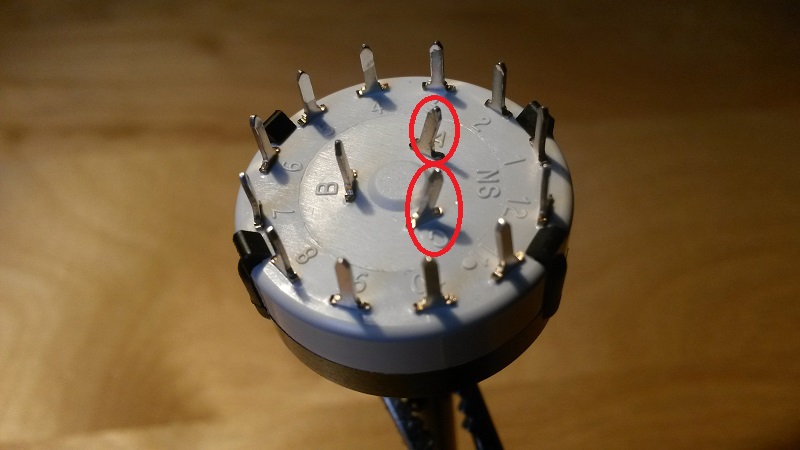

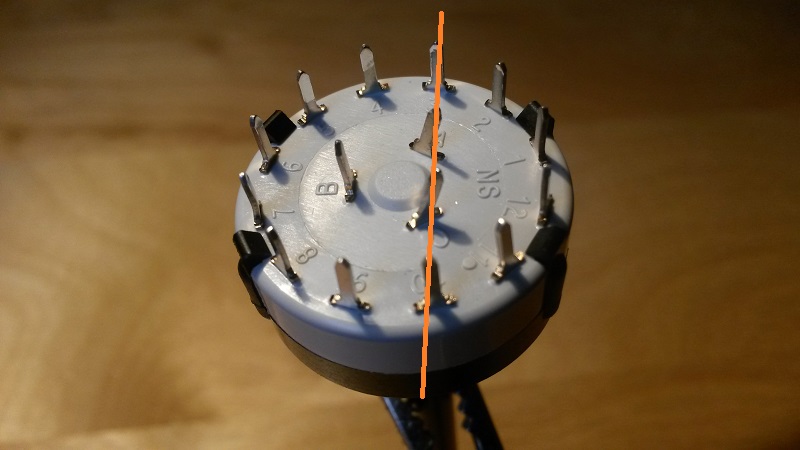

It takes both 2520 and Neumann type DOAs. Two switchable loads are available.

There are four gain settings selectable. Two are set as a inverting amplifier and two

are set to non-inverting.

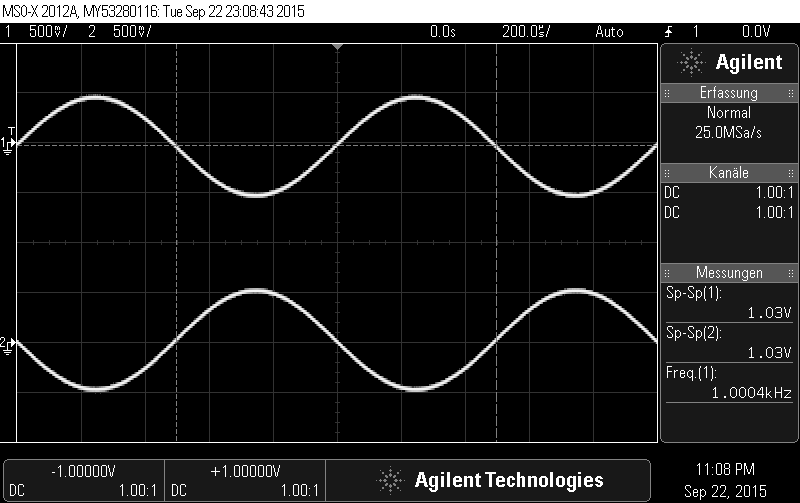

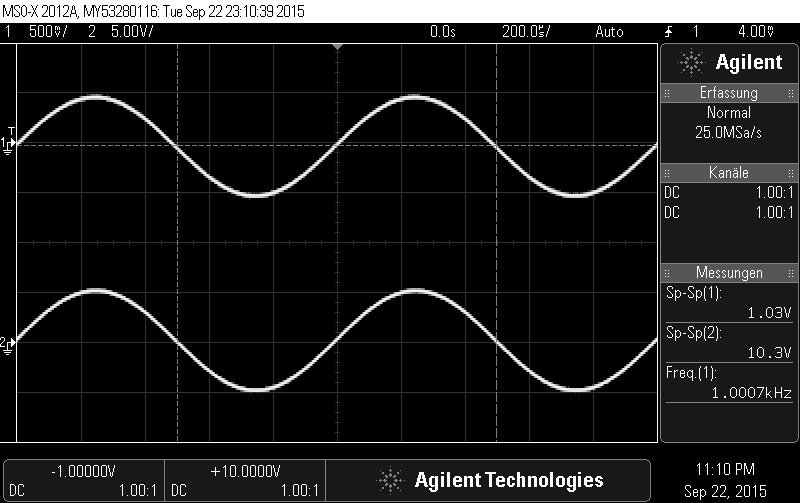

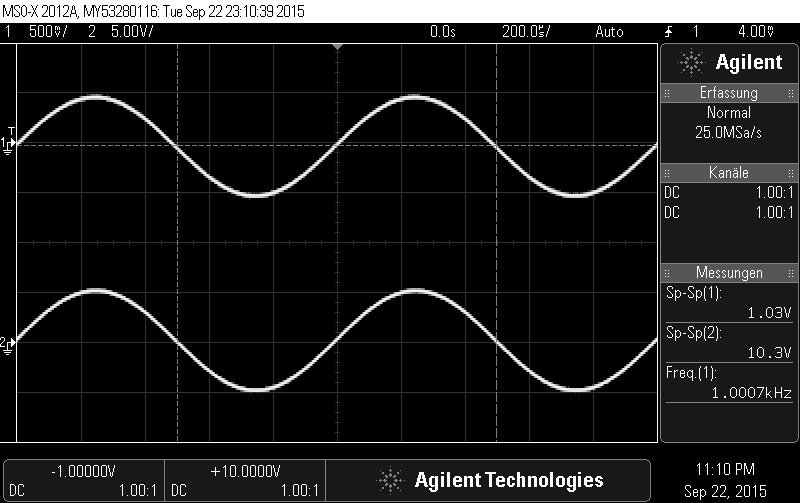

The two pictures below show a screen capture from a measurement. Channel 1 is the

input signal and channel 2 the output of the DOA. The first capture depicts a inverting

amp with a gain of 0 dB. The second one has 20 dB of gain in non-inverting set-up:

The board comes in quite handy when assembling and testing DOAs.

Thanks to Volker for the prototype testing!

Questions and comments are welcome

Cheers,

Carsten

I just wanted to share my DOA Test Jig with you:

It takes both 2520 and Neumann type DOAs. Two switchable loads are available.

There are four gain settings selectable. Two are set as a inverting amplifier and two

are set to non-inverting.

The two pictures below show a screen capture from a measurement. Channel 1 is the

input signal and channel 2 the output of the DOA. The first capture depicts a inverting

amp with a gain of 0 dB. The second one has 20 dB of gain in non-inverting set-up:

The board comes in quite handy when assembling and testing DOAs.

Thanks to Volker for the prototype testing!

Questions and comments are welcome

Cheers,

Carsten