80hinhiding

Well-known member

- Joined

- Sep 27, 2016

- Messages

- 97

.

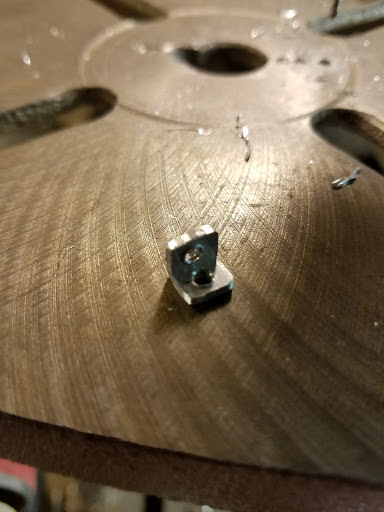

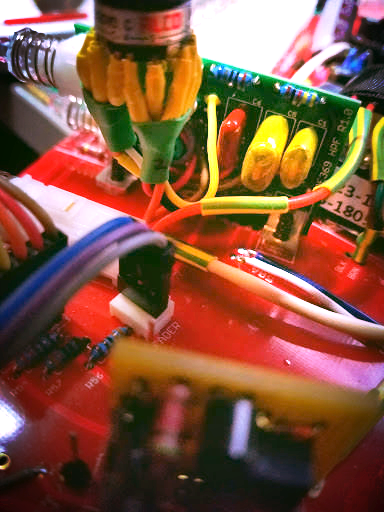

80hinhiding said:For me right now, the bottom line is getting this project finished to a high standard, without spending too much more money. I saved these panels from despair and thought this would be celebrated on a site about DIY. I'm happy to find out just how cleanly you can do this by hand.. with a few not so expensive tools.

I'm happy to find out just how cleanly you can do this by hand.. with a few not so expensive tools.

It's hard work, and very involved. It'll take over your life

Enter your email address to join: