Before everyone goes Dremel crazy here are a couple of other ideas.

@Pierre: don't feel too bad - I've fixed enough 'professional' boards with far worse kludges than this - and in some quite 'name' gear too.

Worst mirror image problem was in a batch of boards I had to rework for a local disco light company: they'd mirrored the TRIACs ....... the first tests of boards were spectacular to say the least, until they spotted the problem, (for the non electronics people I might explain that a TRIAC is used to switch mains power to the lights, mirroring a package puts the mains on the control terminal - and they explode, literally!).

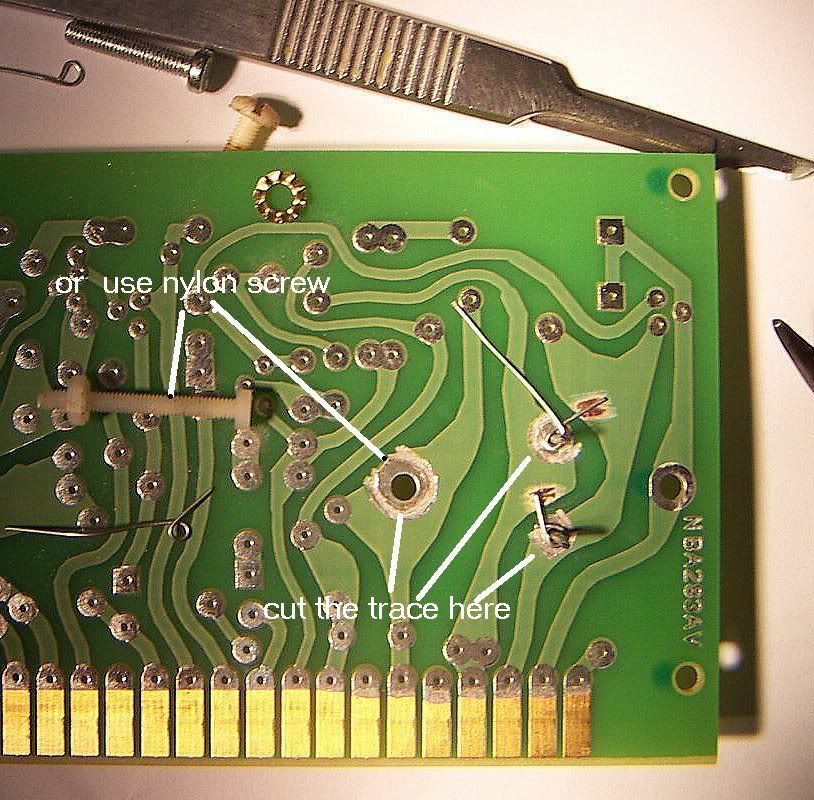

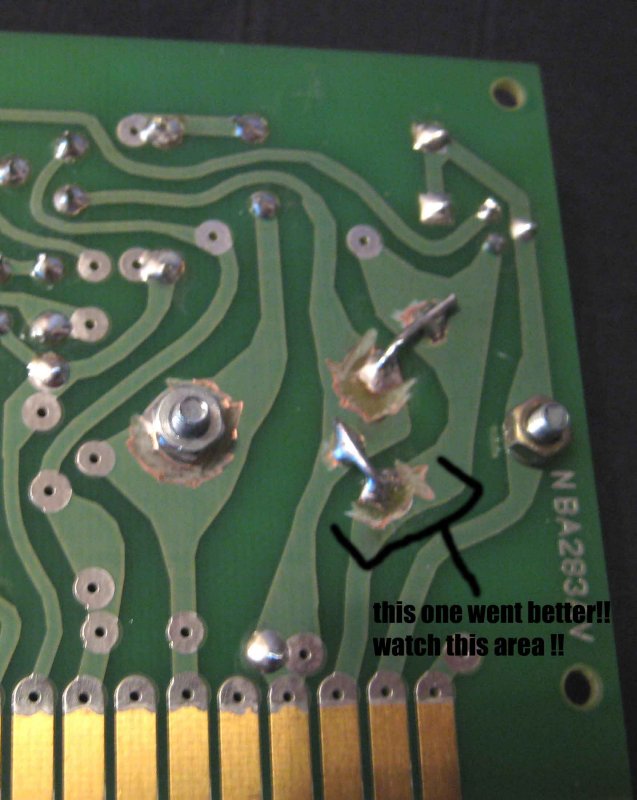

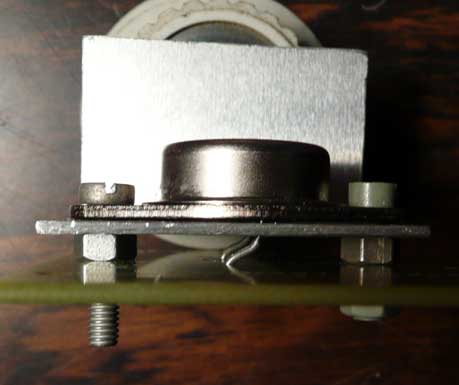

First idea: Don't lower the floor, raise the ceiling. Not a new trick, but easy if your heatsink isn't too thick. I just knocked up the bit of alloy to make the trick show more easily - this is not my actual heatsink. A bit of PTFE sleeving over the pins would be good. I've used a nylon bolt for the faulty hole. Relatively easy, and no board modding, (and possibly better air flow).

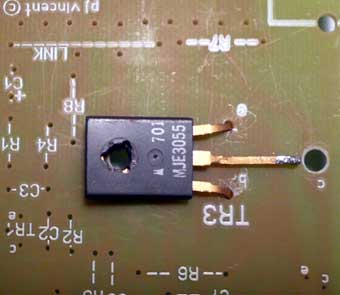

Second idea - go lateral. use an MJE3055 of TIP3055. You'll nee to fab up a different fin, and use a nylon bolt again. I haven't extended the centre (collector), lead - it needs to be slightly extended down the original hole. A later check shows that some 'flat pack' heatsinks will fit without modification. the taller twisted fin type should be OK.

[EDIT] I've just pulled some various 'flat pack 3055' data sheets. You'll have to watch the pin outs - some are (L->R) BCE others ECB. Both can be made to fit - just that, obviously, there is a need to check.

By the way: before for any authenticity fetishist says "it's not a 3055", I might point out that 60% of what is labelled 3055 isn't either, unless you buy from a major company. Most 3055's are regarded as 'generic NPN power' and sourced from production drop outs of higher rated devices. The flat pack ones at least come from a major maker, and will have the correct semiconductor die inside the package. At this power level, heat transfer is not going to be an issue, (the flat pack ones have a slightly lower max power dissipation).

[EDIT] Doing some 3055 checking reveals that quite a few bigger makes may be 'selects' too. One Motorola data sheet quoted Ft anywhere from 0.6 MHz to 6MHz. Typical should be 2MHz, looking back at an old original RCA data book. Flat pack 3055's all seem to have a lower max current of around 10A, as opposed to 15 in the T03, (due to package limitations). Not really relevant here - the die is theoretically the same.

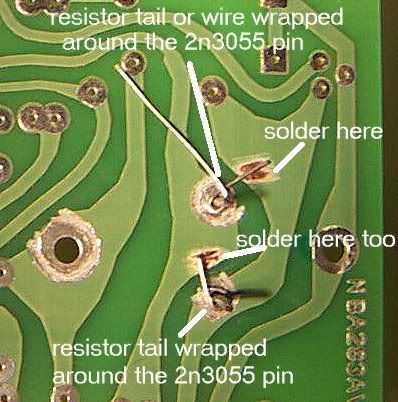

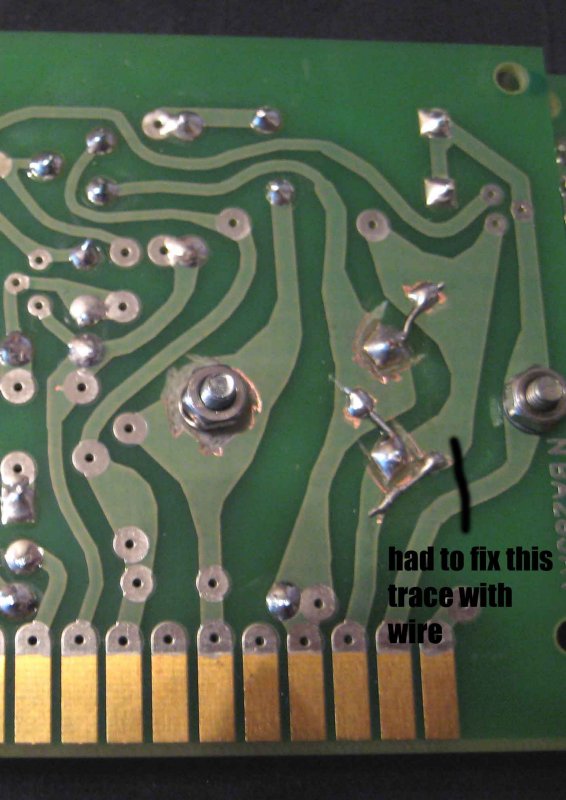

I think the flying heat sink method is the easiest. A Hint: when bending the pins, hold the pin next to the case with your needle nosed pliers to avoid cracking the seal. Another option is to solder some wire on to go down the holes and trim the pins to clear the board.