DIYnoob!

Well-known member

a lovely walk in the garden

Svart said:I've just now found this while searching online for cheap 500 series racks..

How did I completely miss this thread for so long??

I'm in line with everyone else for one of these babies..

depends ;DDIYnoob! said:is the PSU separate from the rack?

Sahib,sahib said:...What a day to have a birthday...

sahib said:Birthday of two things.

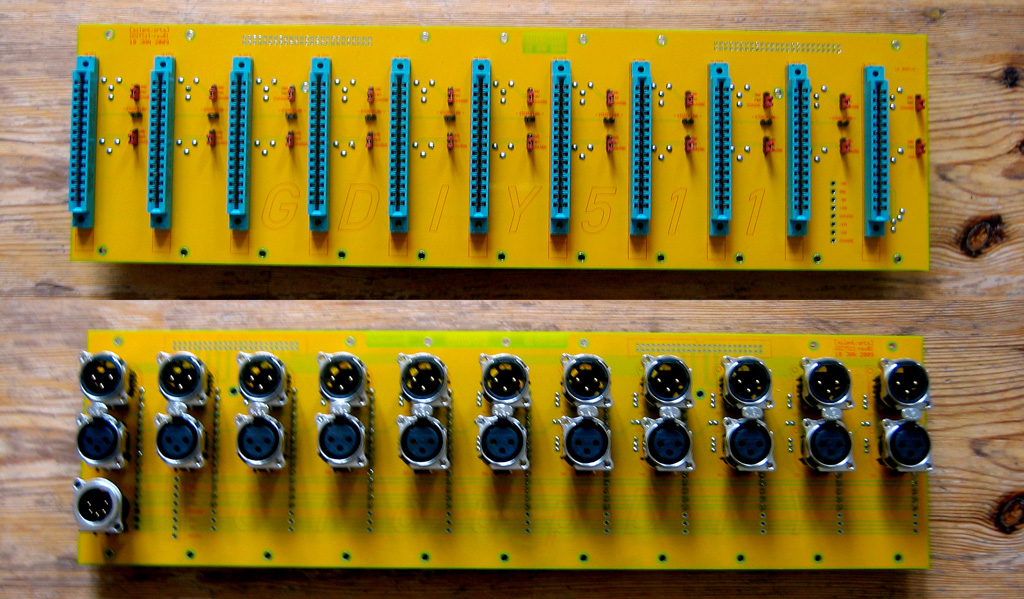

sahib said:Second is GDIY511 and GDIY512 cases. Picture is for GDIY511 but 12 is the same, except 12 slot. I have just collected the protos from the fabricator and it looks all good. They are not powder coated yet as I still have to work out the location of the D25 connectors and fit Volker's pcb to make sure everything is working out.

However, I am still so young and good looking that if I posted my picture here you would all fall into depression

My son's team did not win. I have already disowned him and he is walking back from the school. And if the tea is not on the table tonight at 7 o'clock sharp wife will also get her P45.