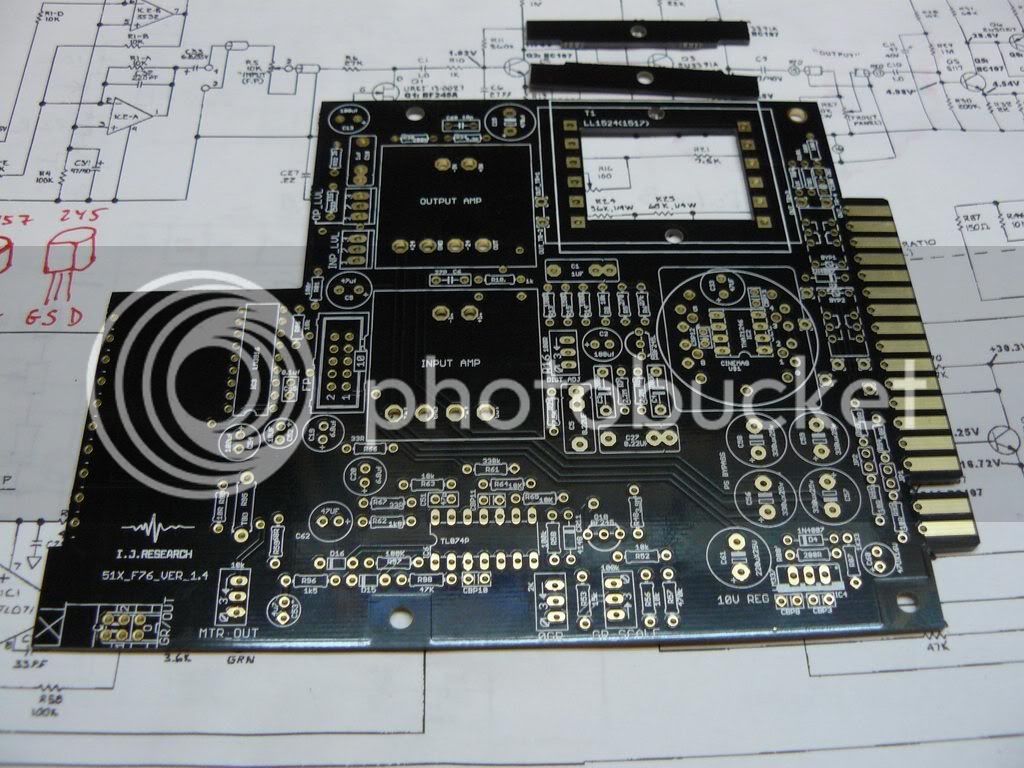

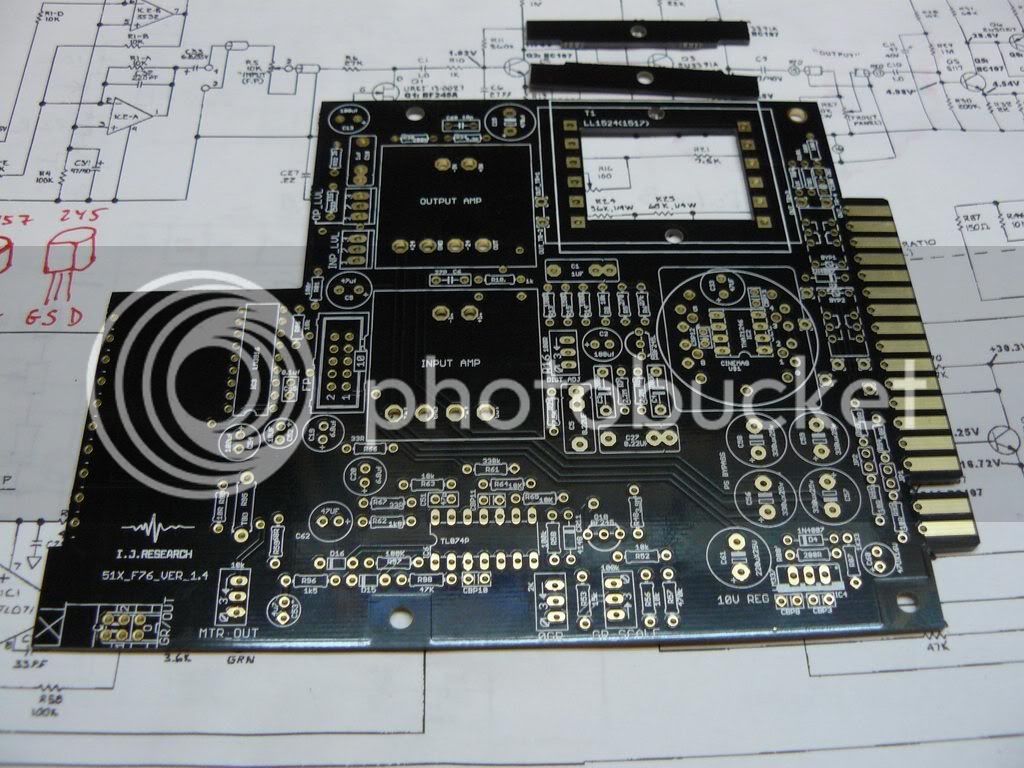

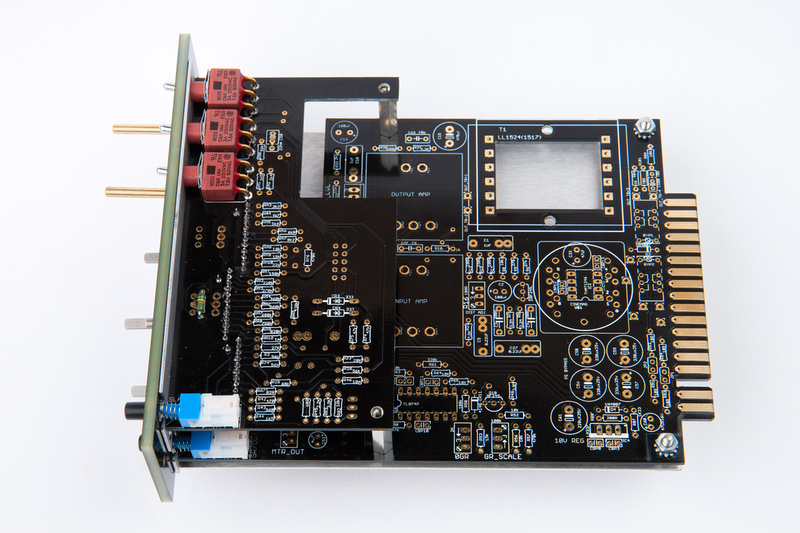

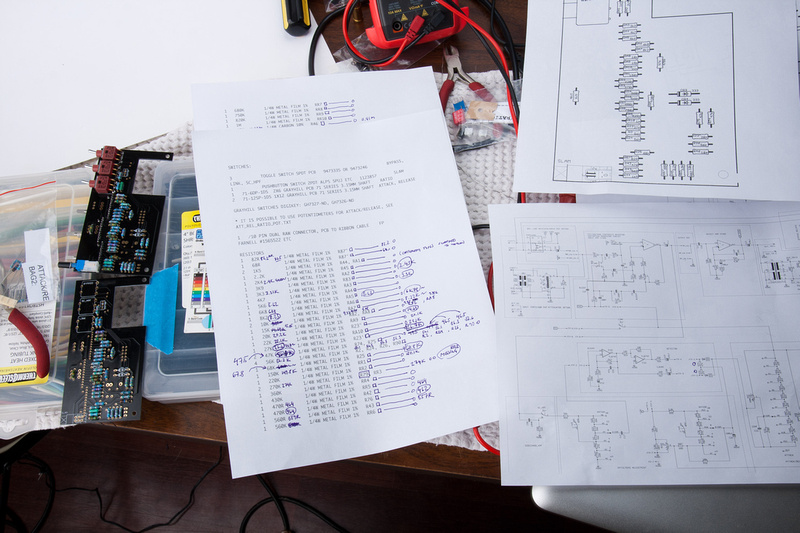

A little more progress on my f76 build. . . I heard rumor from a few people that there were some mechanical assembly difficulties with the kit, so I decided next, I would try to assemble the major components to discover what those difficulties are and figure out a way to shift the tolerances so the build will be as polished-looking as I can manage. I thought this might be important before I started populating the PCB's so I do not accidentally install a mis-aligned component that is difficult to remove and adjust.

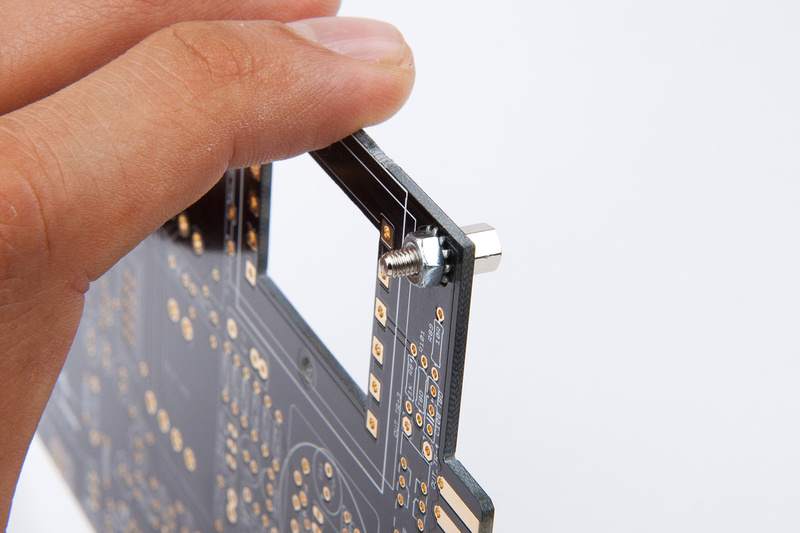

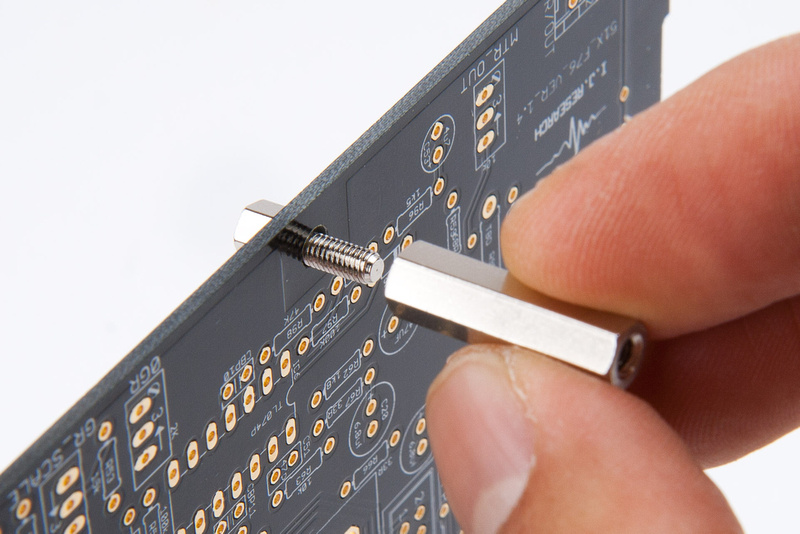

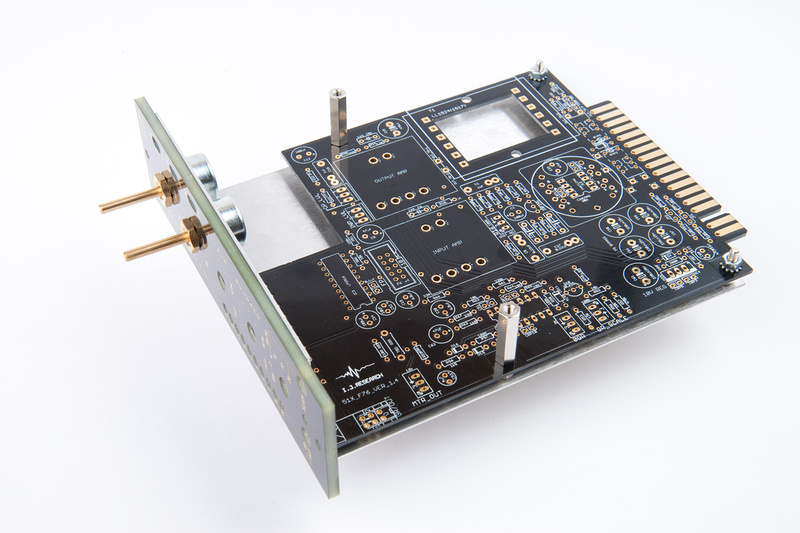

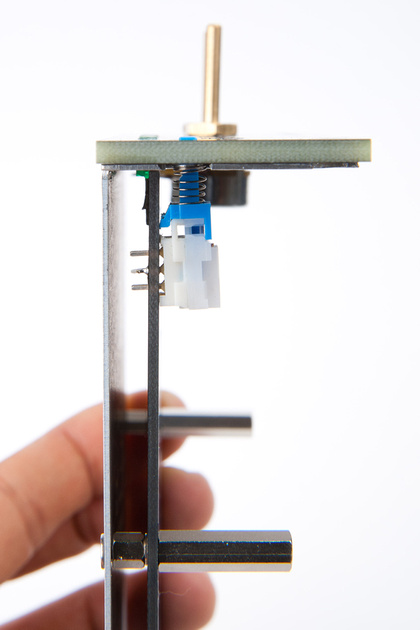

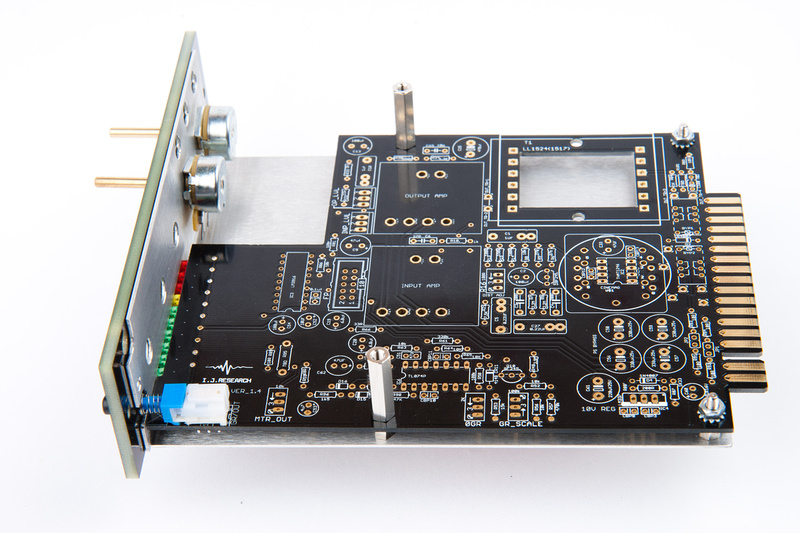

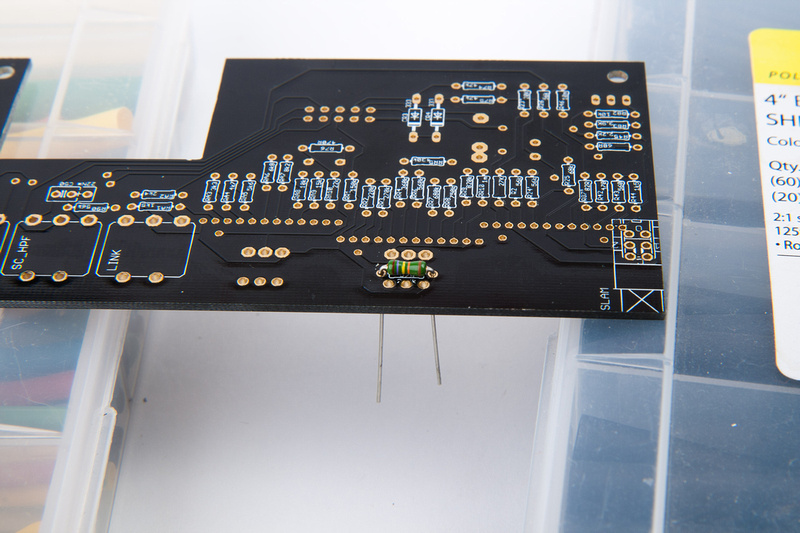

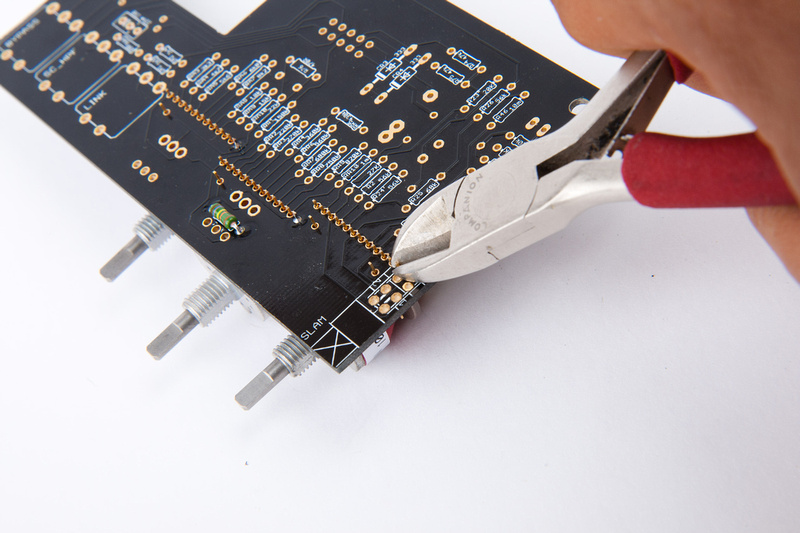

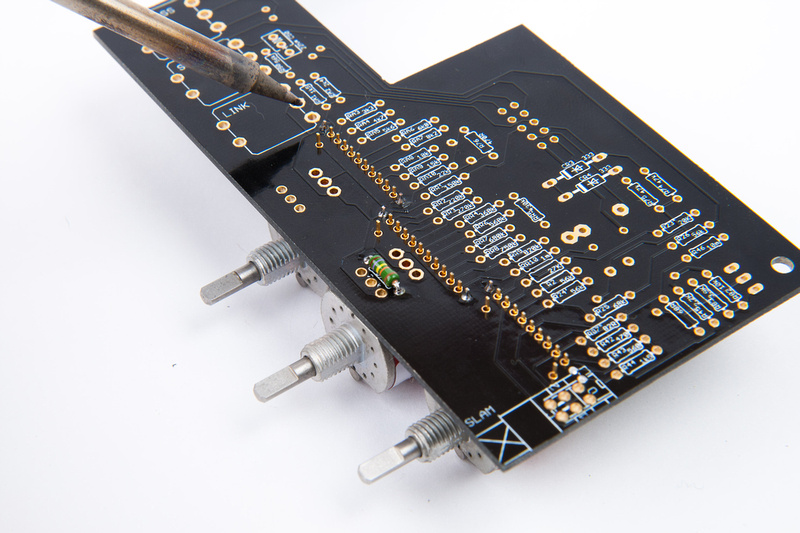

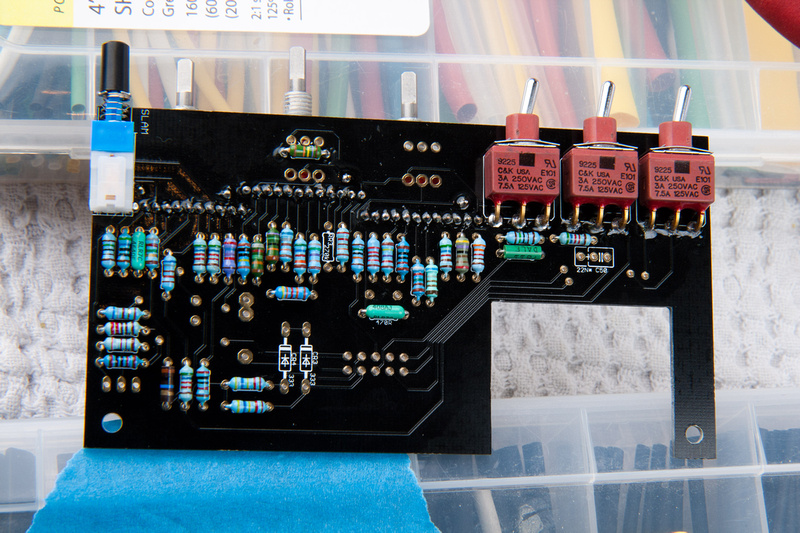

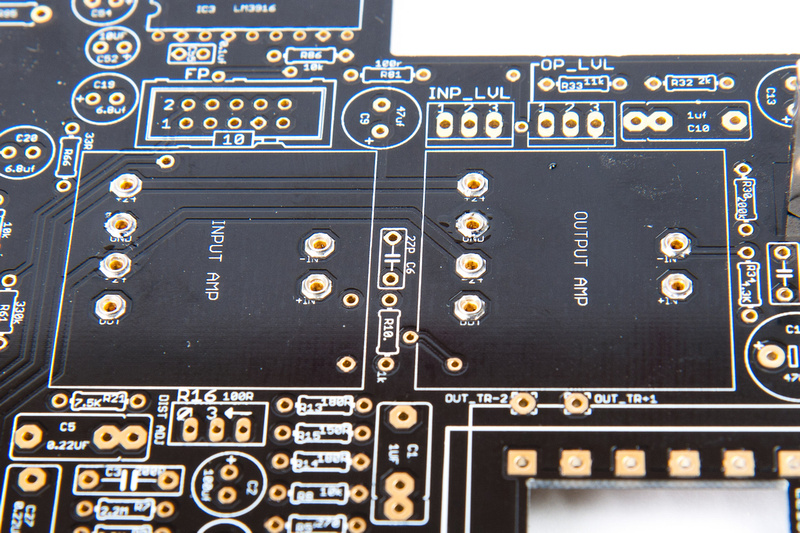

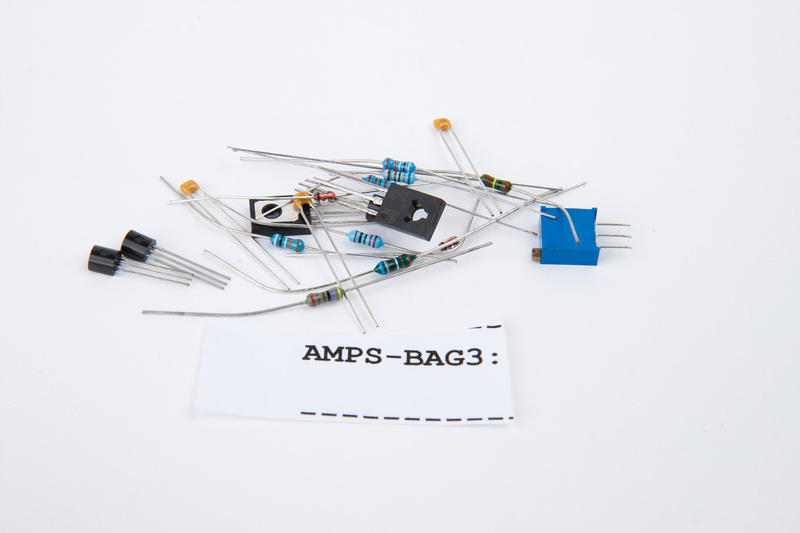

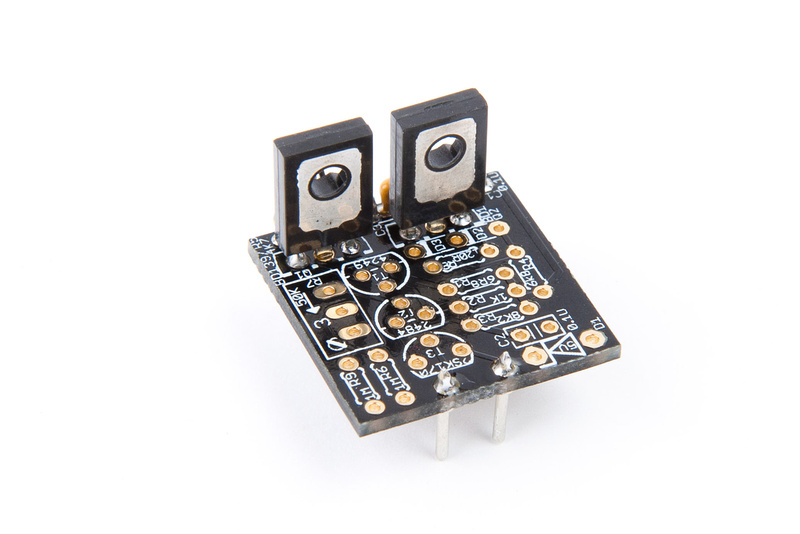

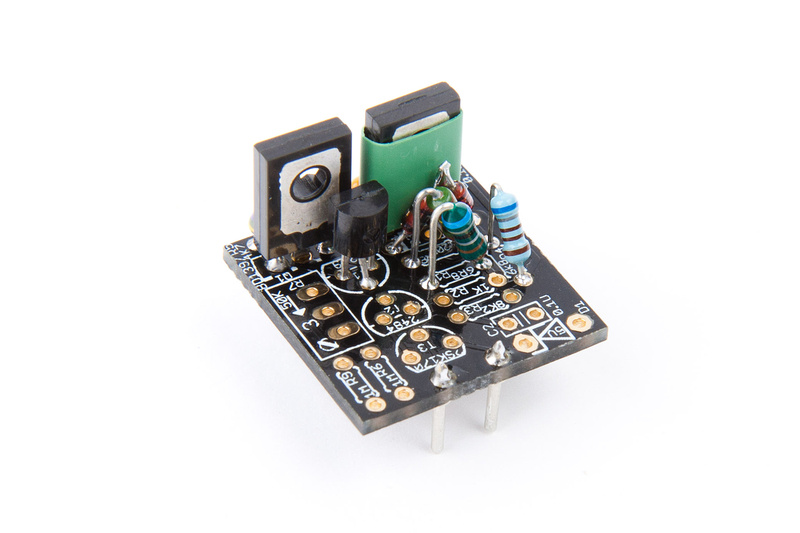

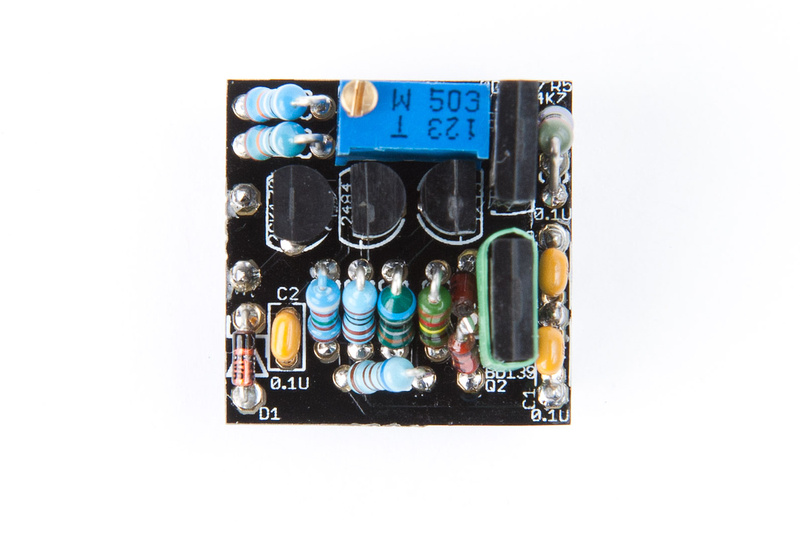

First, I located the main PCB mounting hardware.

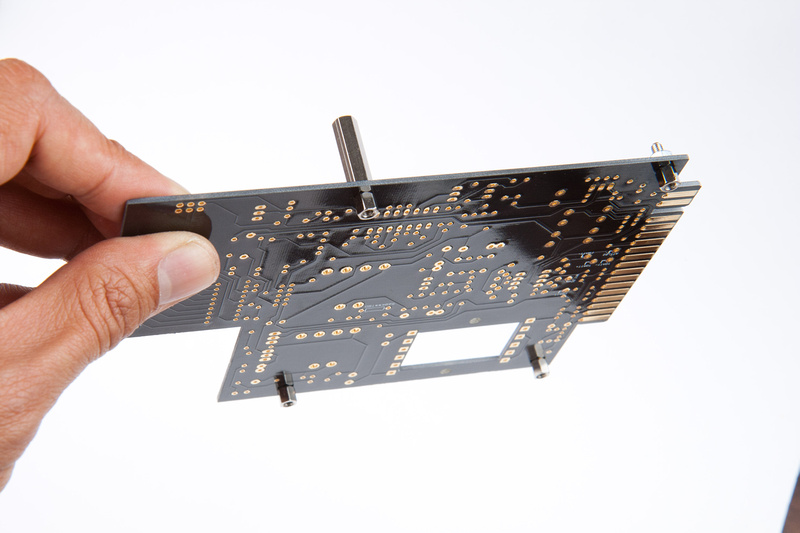

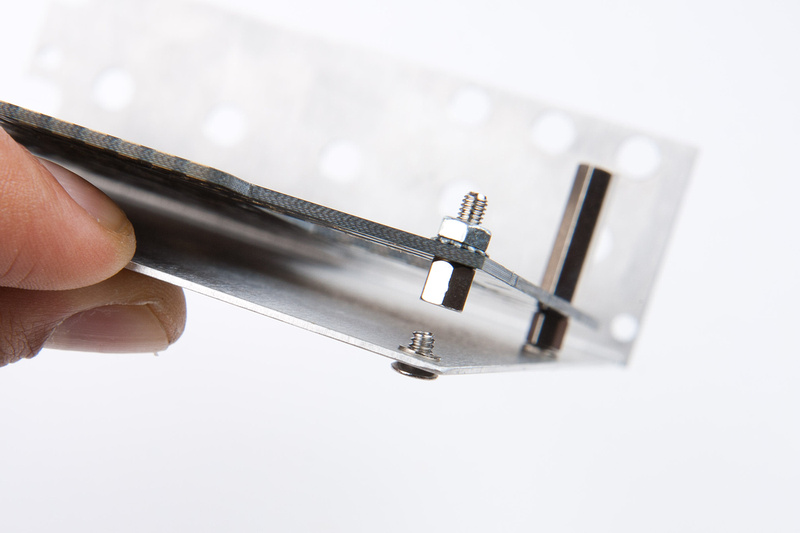

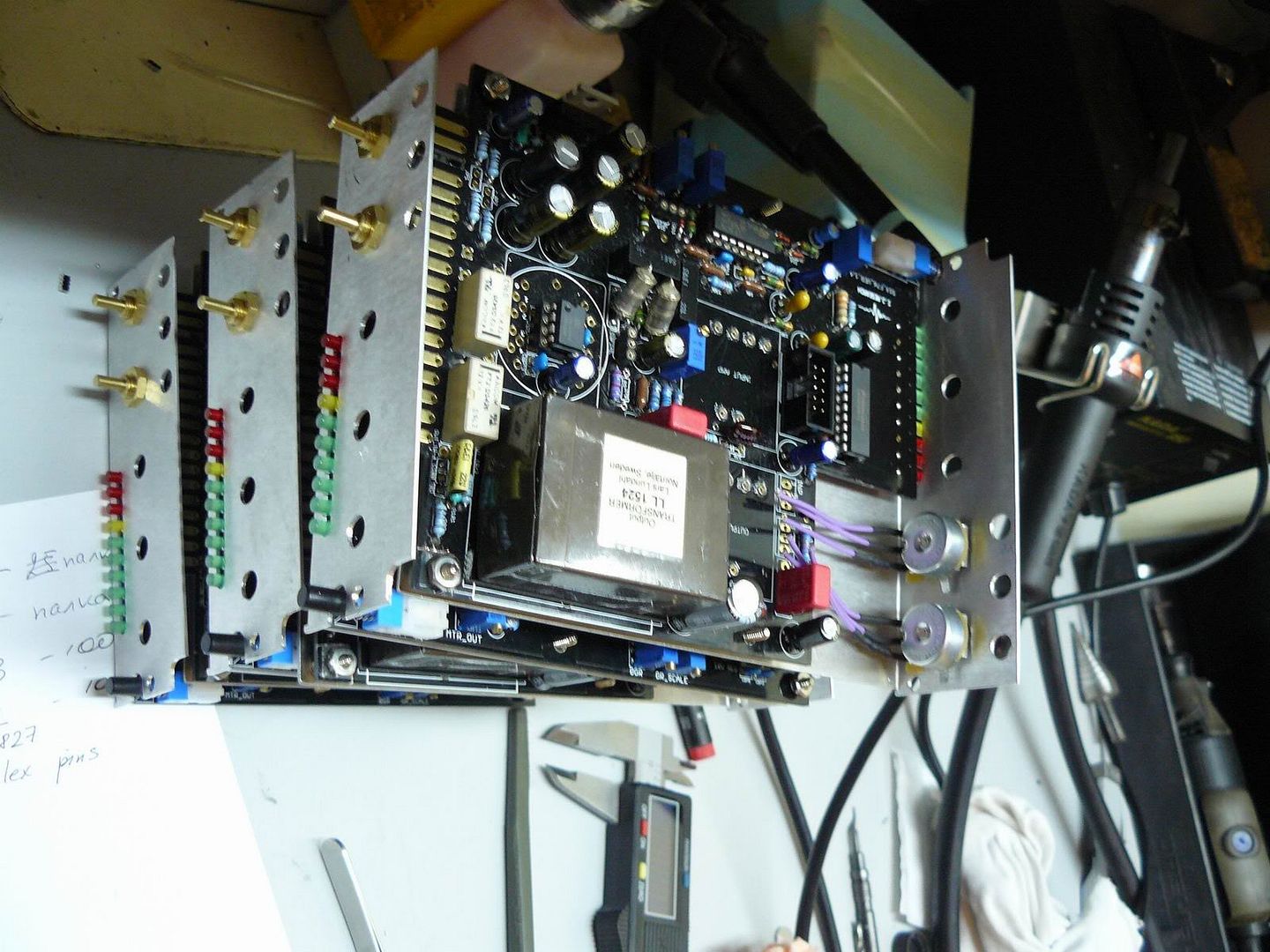

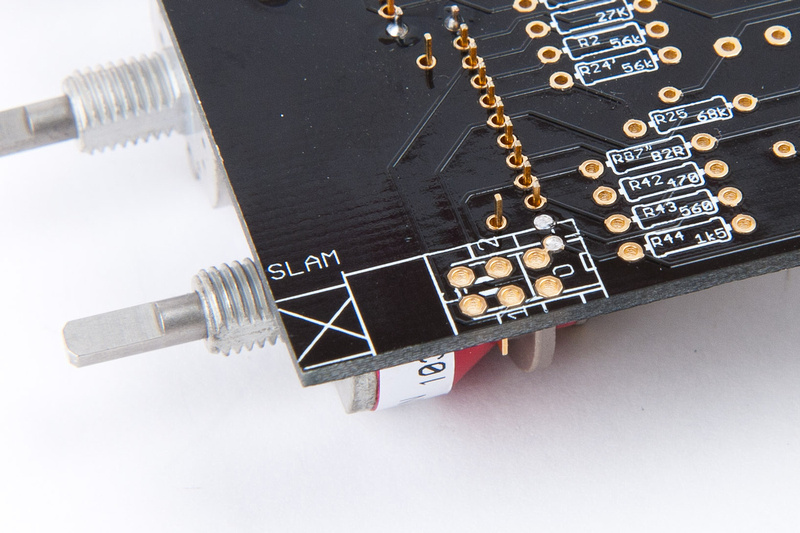

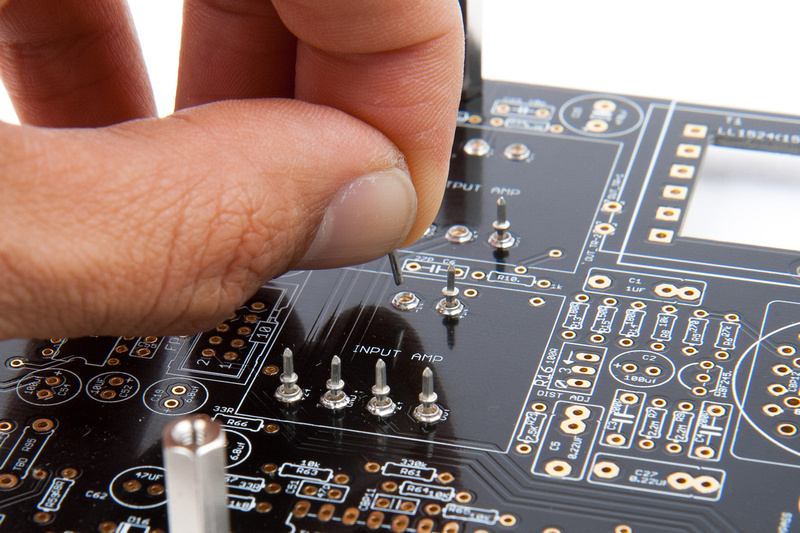

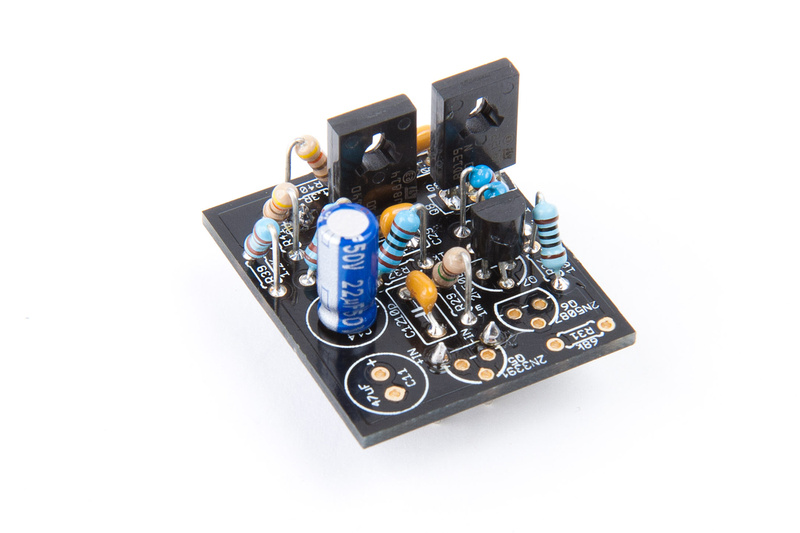

And proceed to temporarily mount the main PCB.

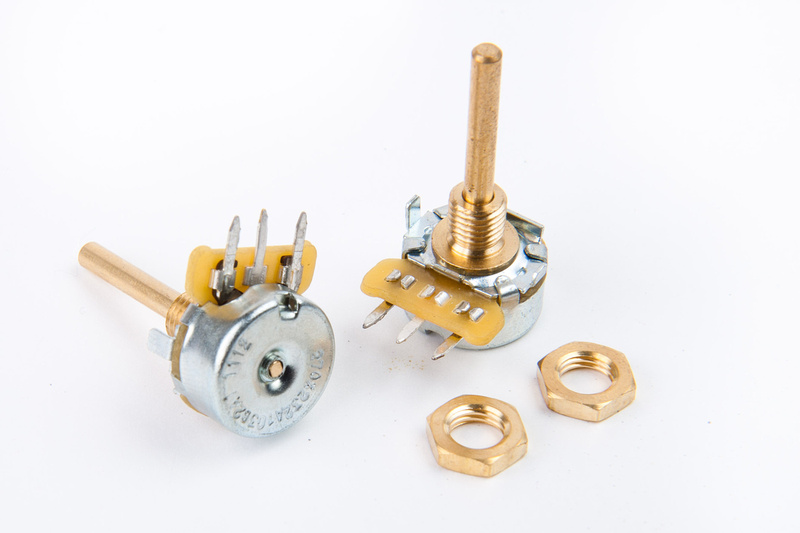

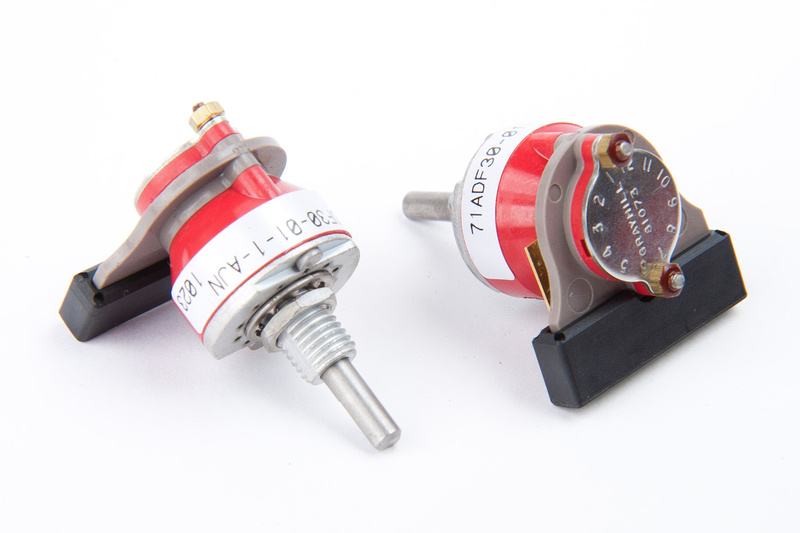

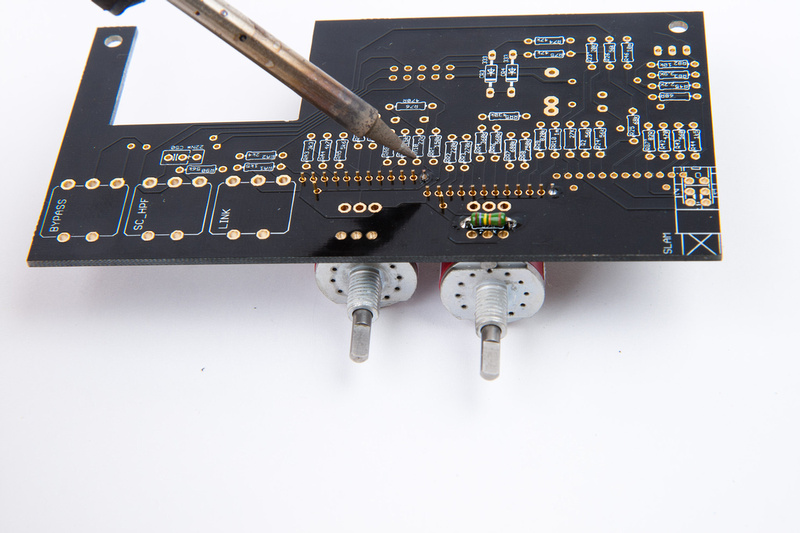

Next, I located my input and output pots along with their nuts.

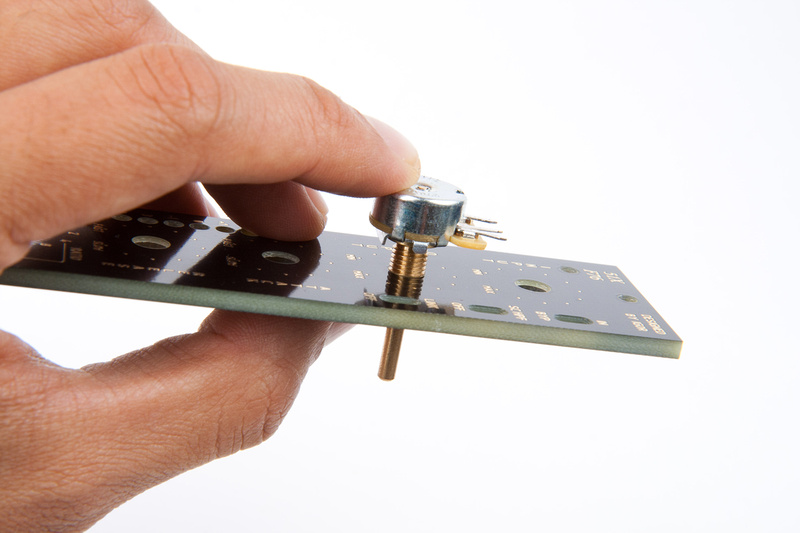

And, discover that they will not mount flush to the L-bracket without slight modification.

so, I modify.

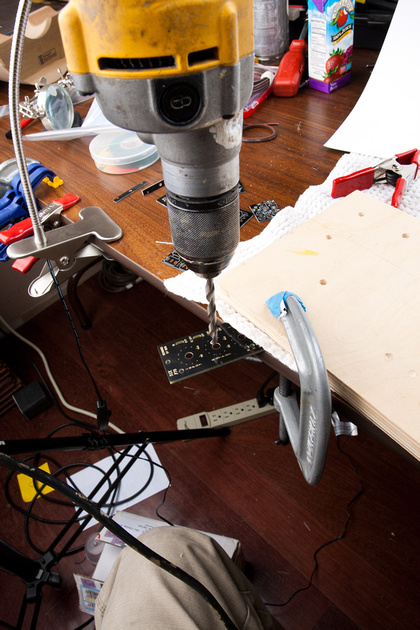

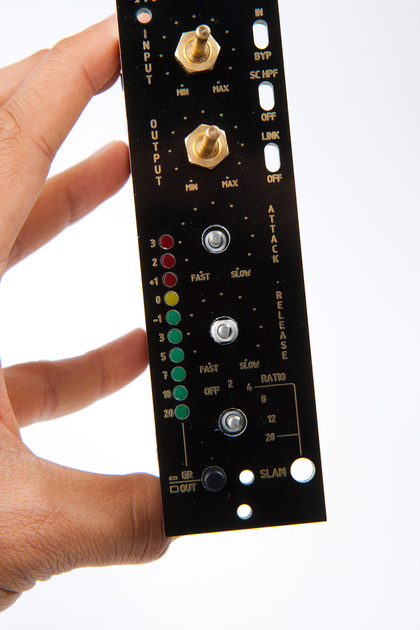

Next, I discover the pots will not fit into the faceplate. . .

So, I use a 1/4" drill bit and open up the holes slightly. I ran my drill backwards to get a smoother cut and try not to damage the nice faceplate.

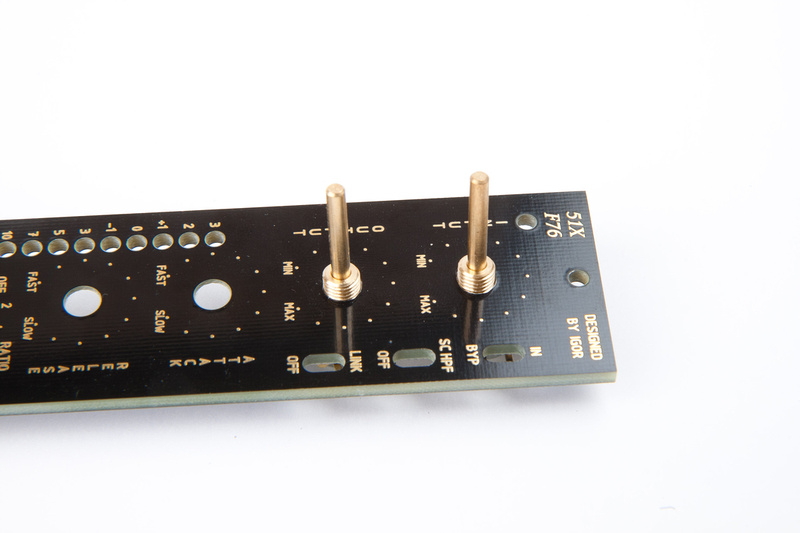

no problem now.

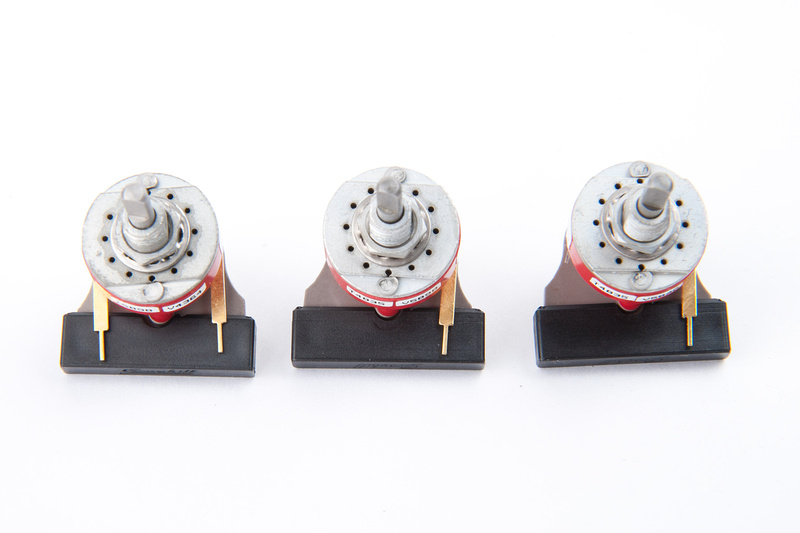

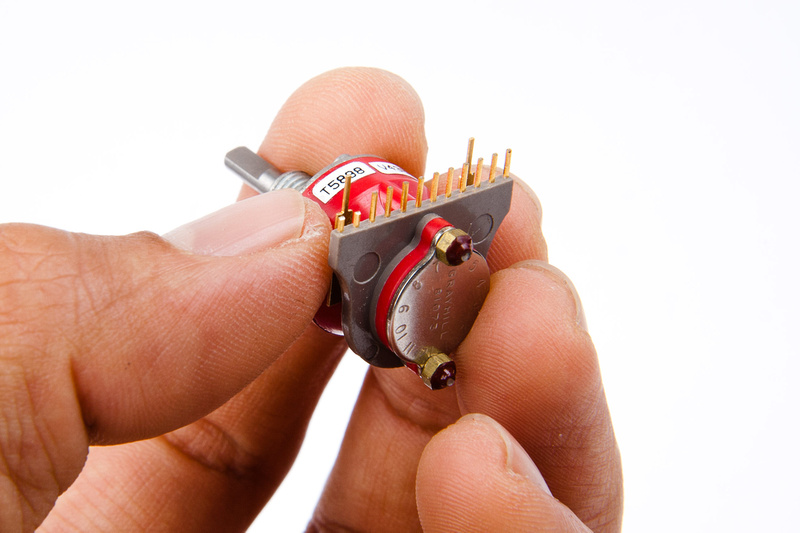

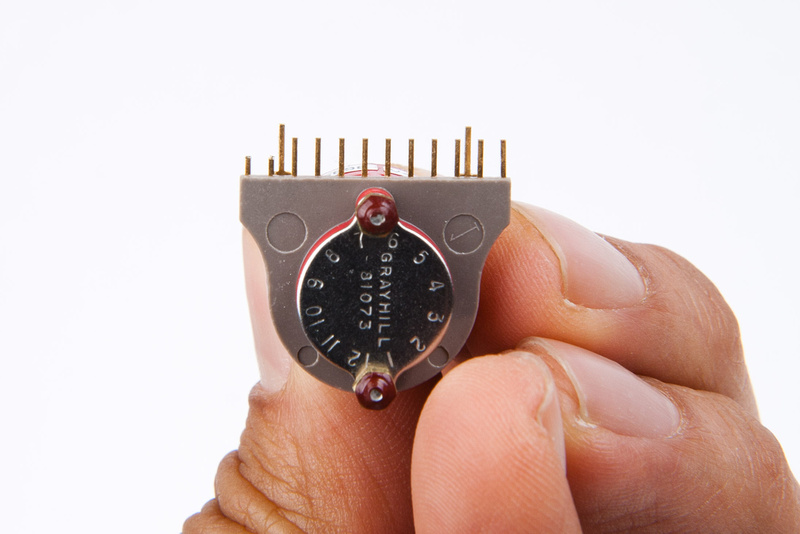

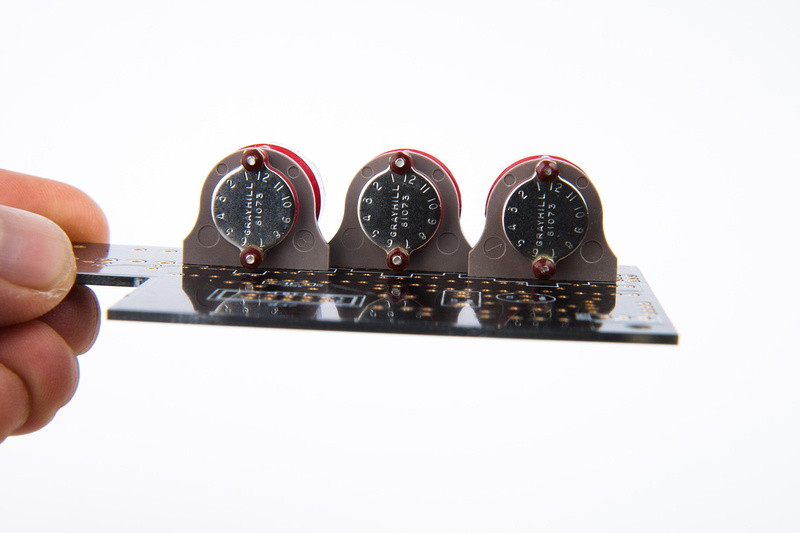

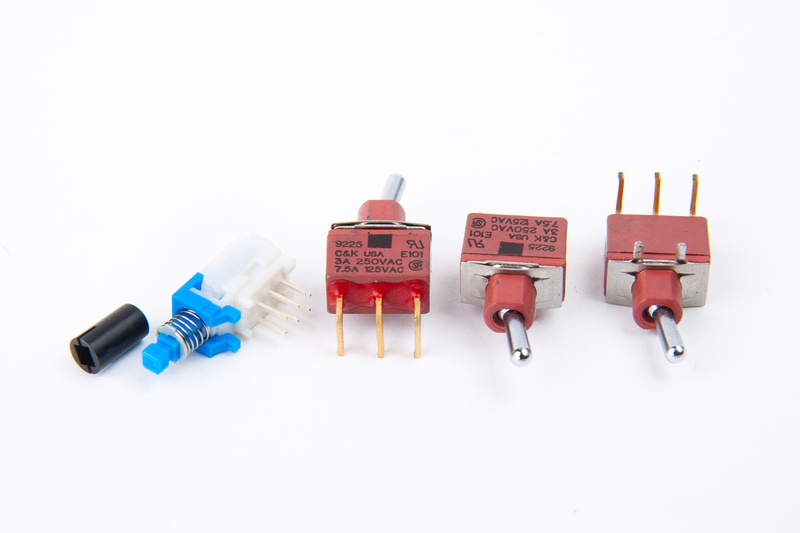

Next, I locate my grayhill switches

I worried for a moment that I would confuse the 2 types of switches and then realized that they have different mounting tabs. . . there is no way to install them in the incorrect locations ;D

But, unfortunately, they also do not fit on the faceplate. . .

So, a bit more drilling for the grayhill switches.

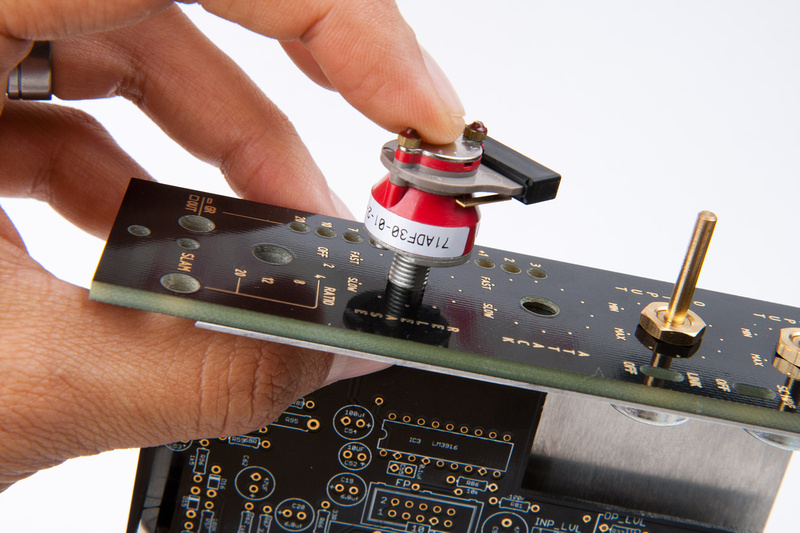

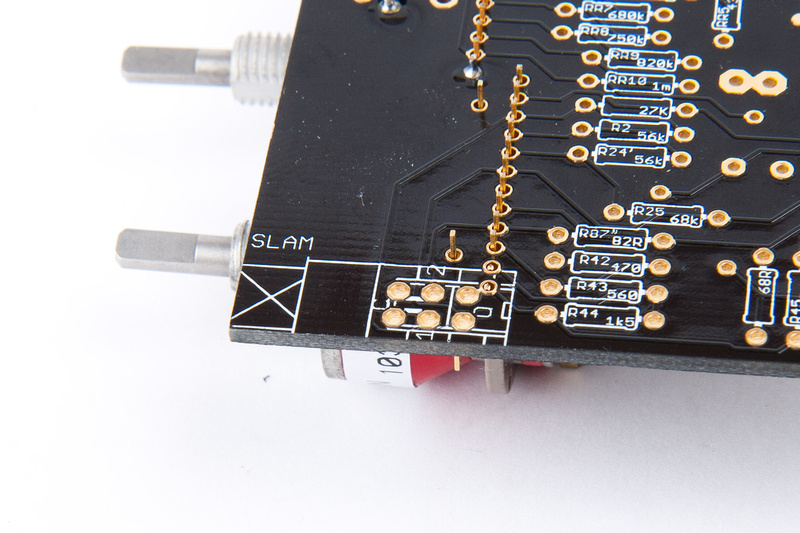

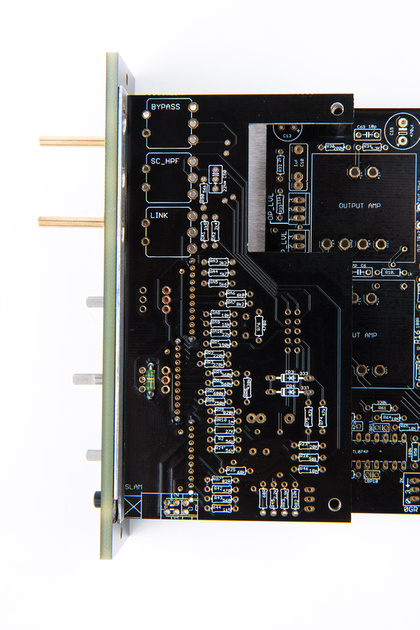

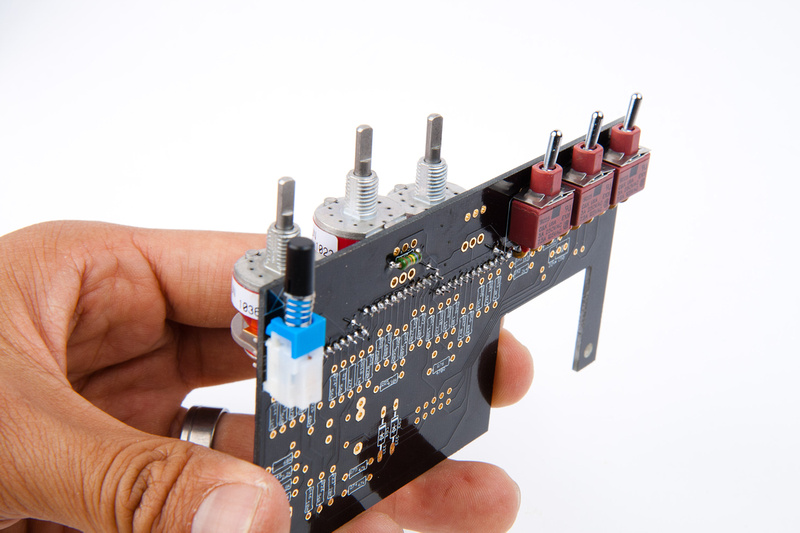

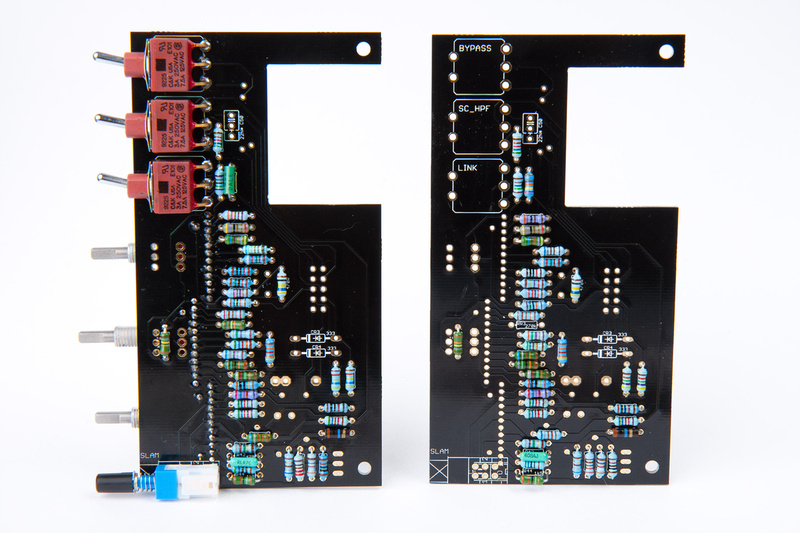

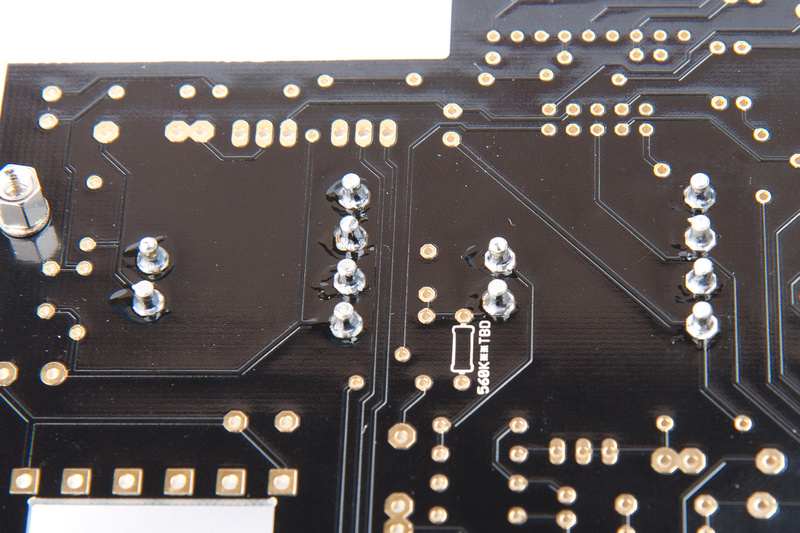

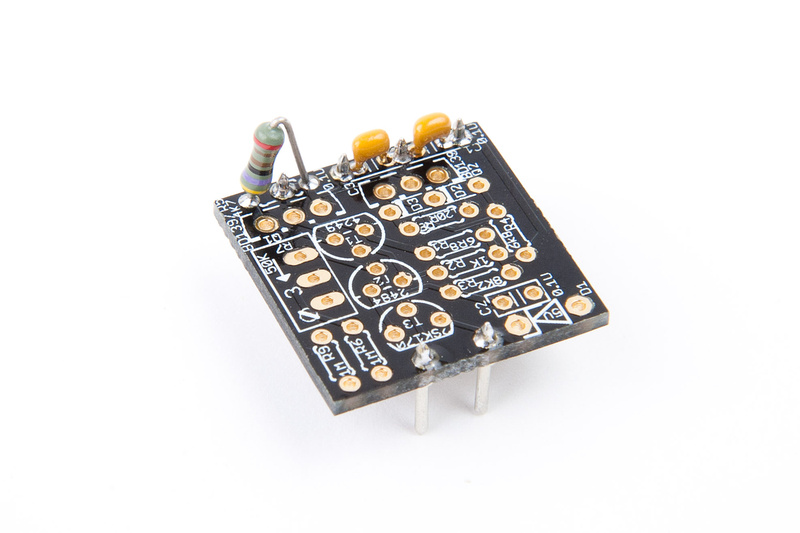

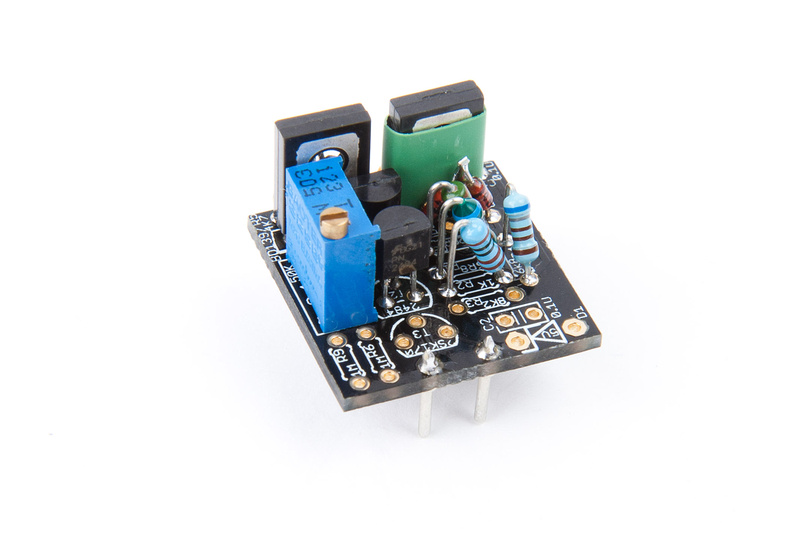

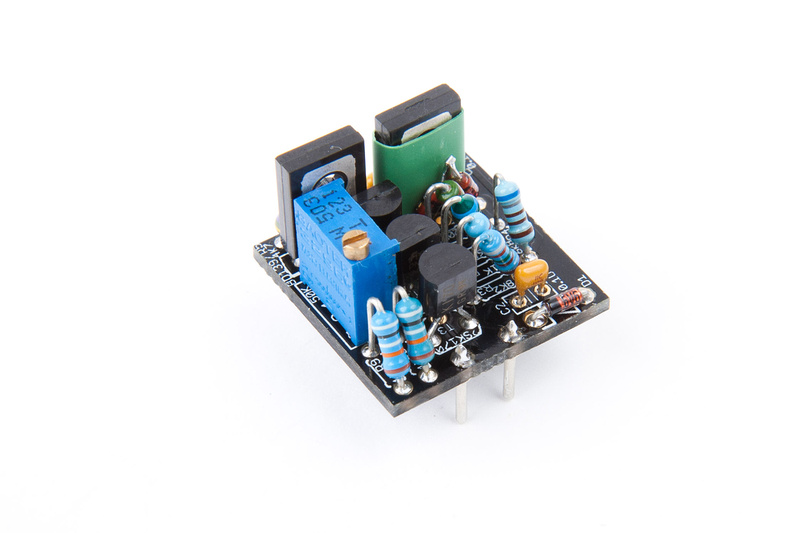

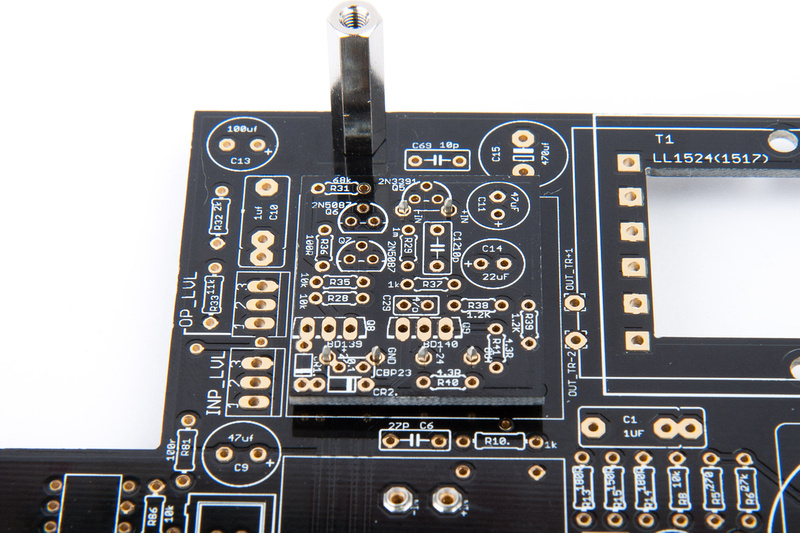

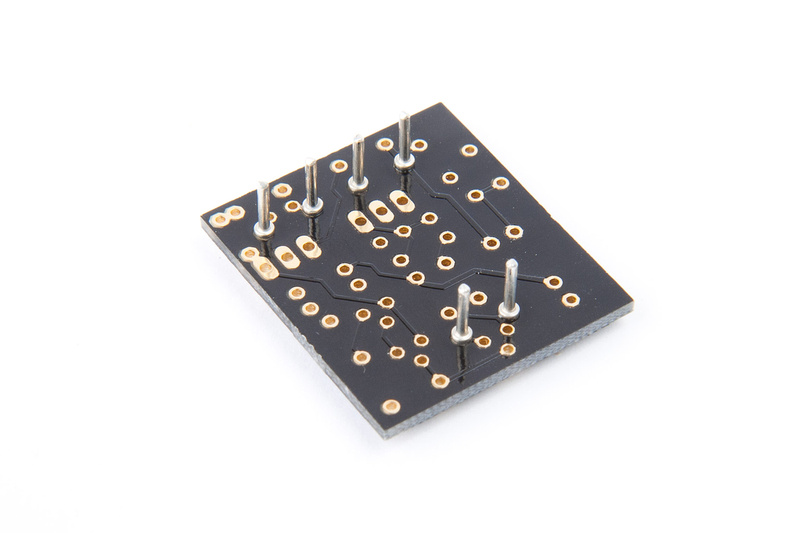

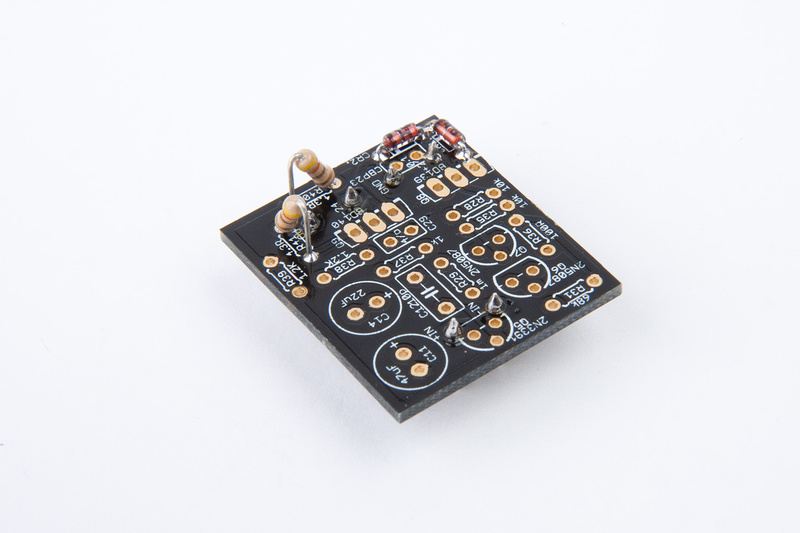

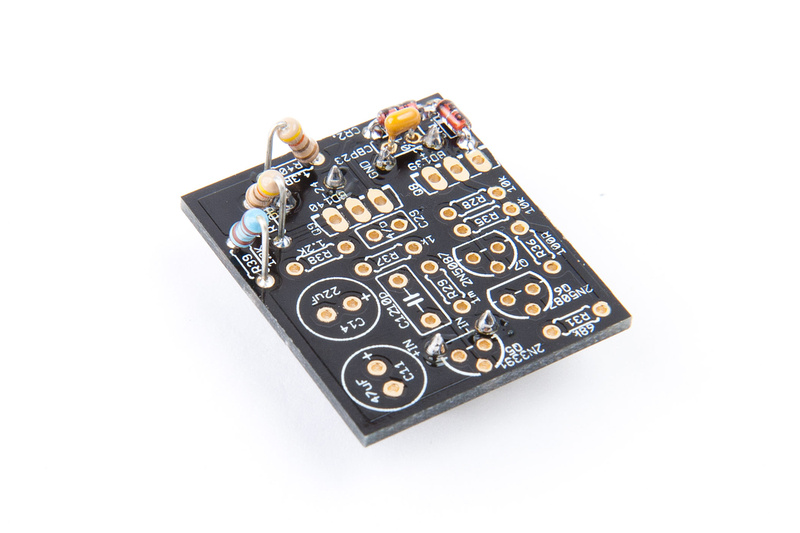

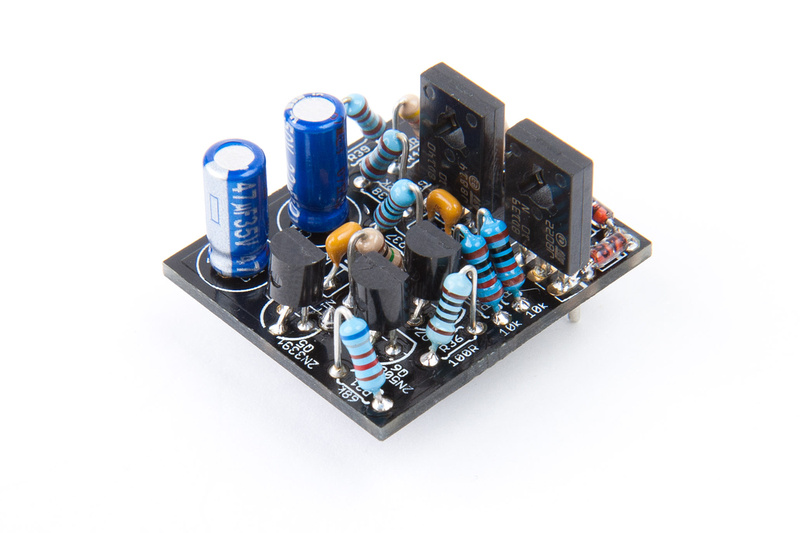

At this point, I take a step back and decide that I should align the main PCB components before moving up to the secondary PCB and the grayhill switches, so I put the grayhills aside and concentrate on the main PCB components.

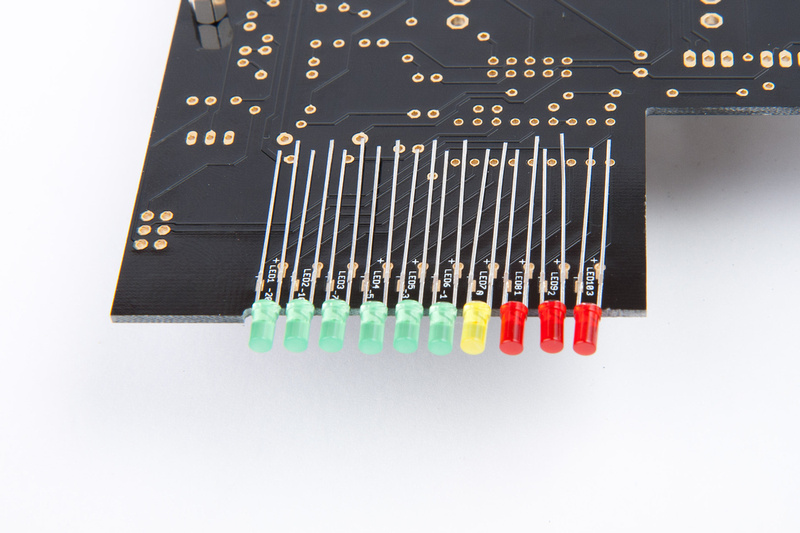

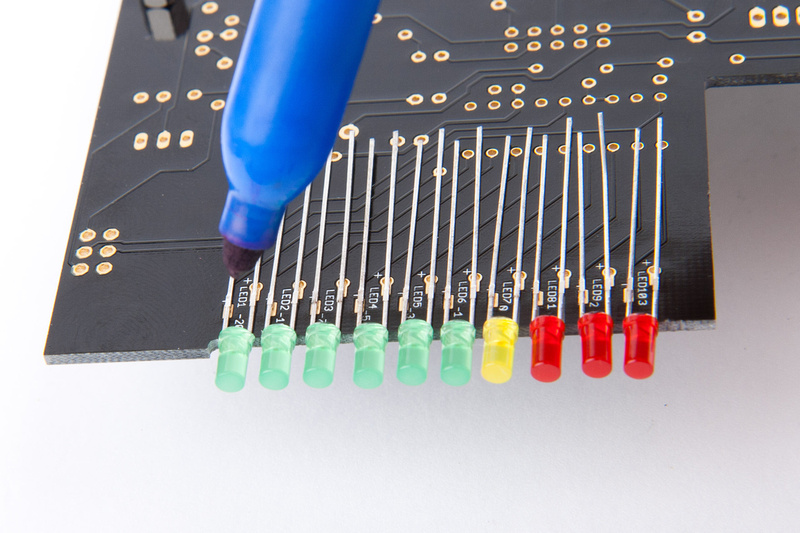

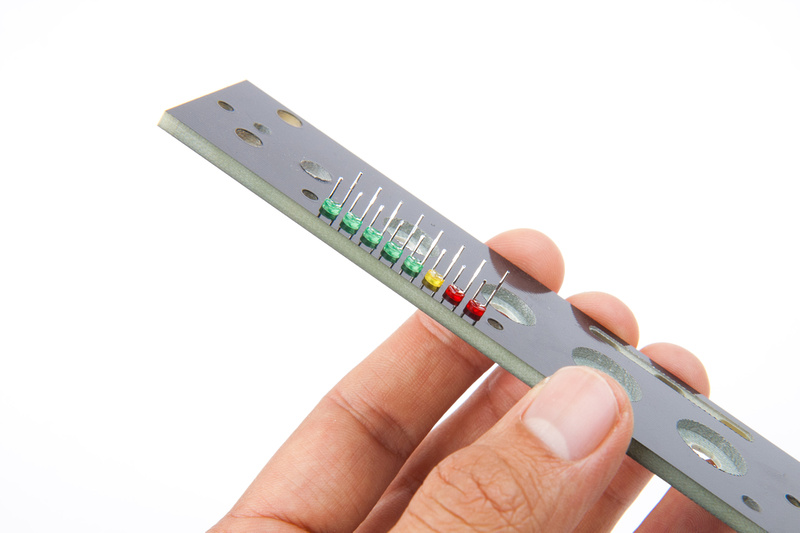

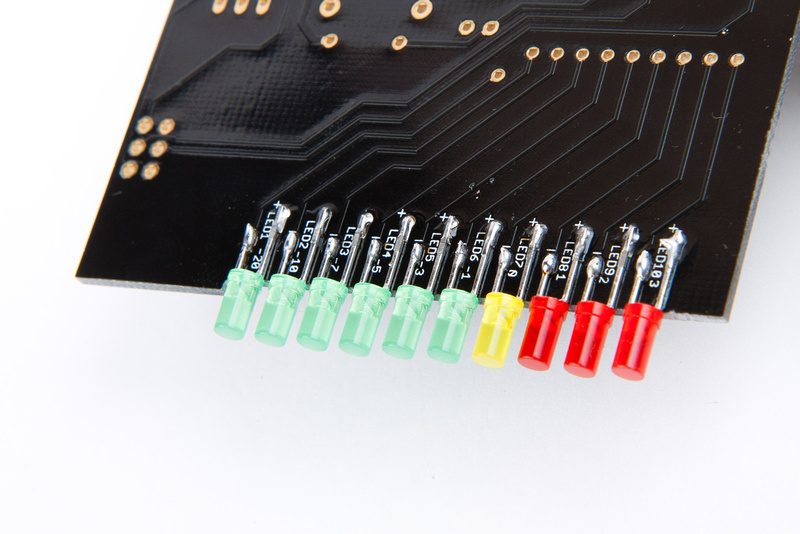

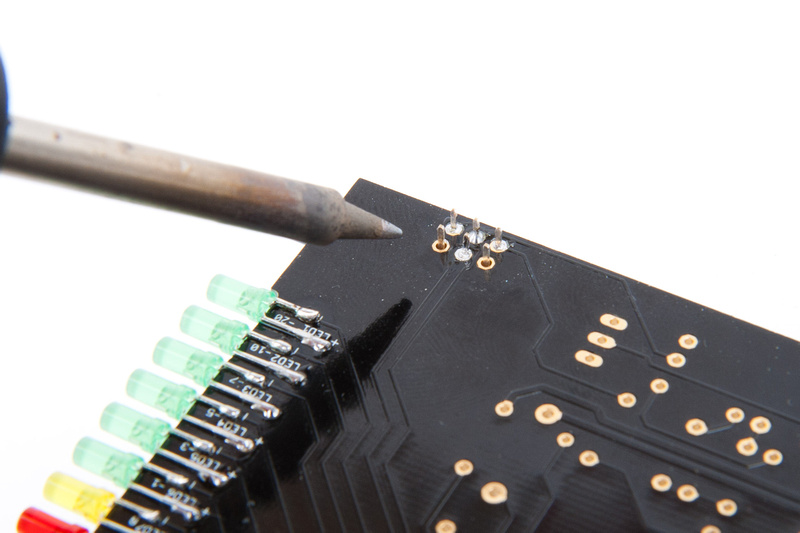

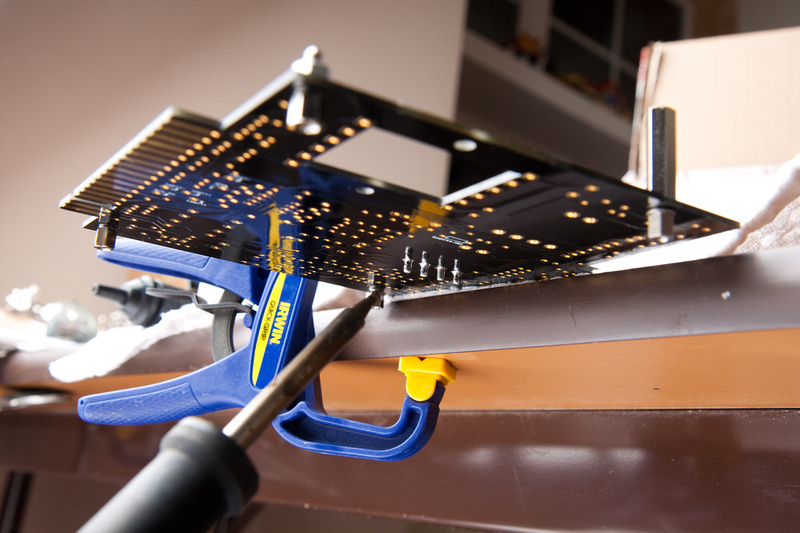

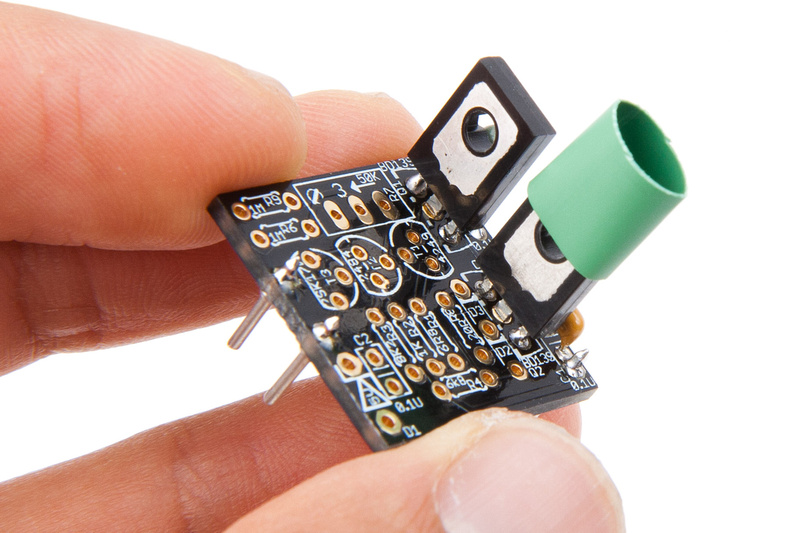

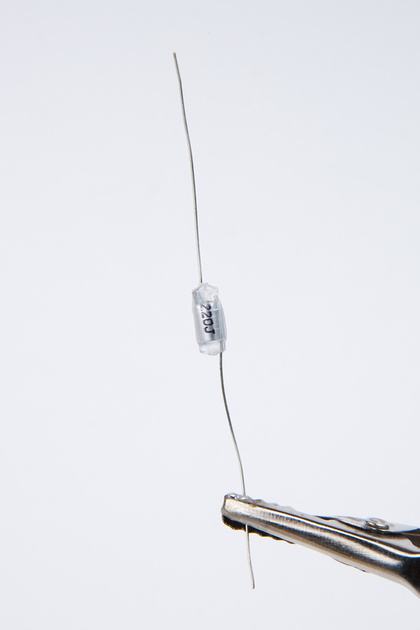

Next, I install LED's as clearly described in this thread by Igor.

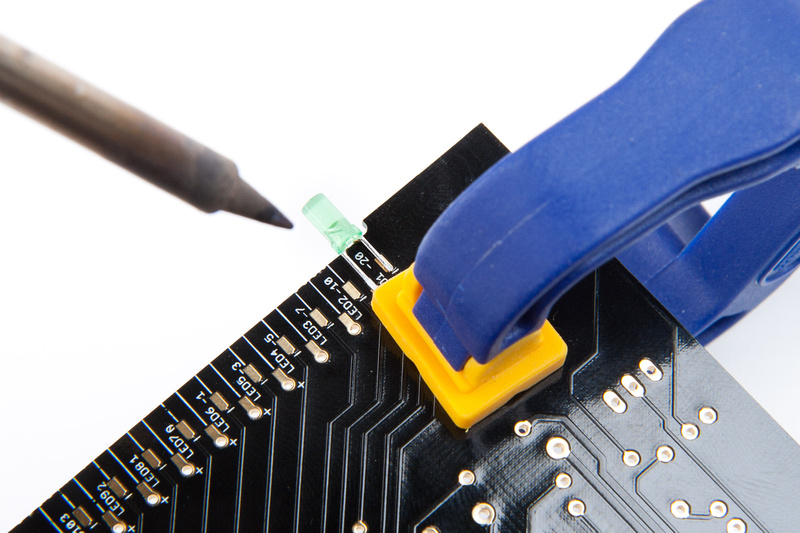

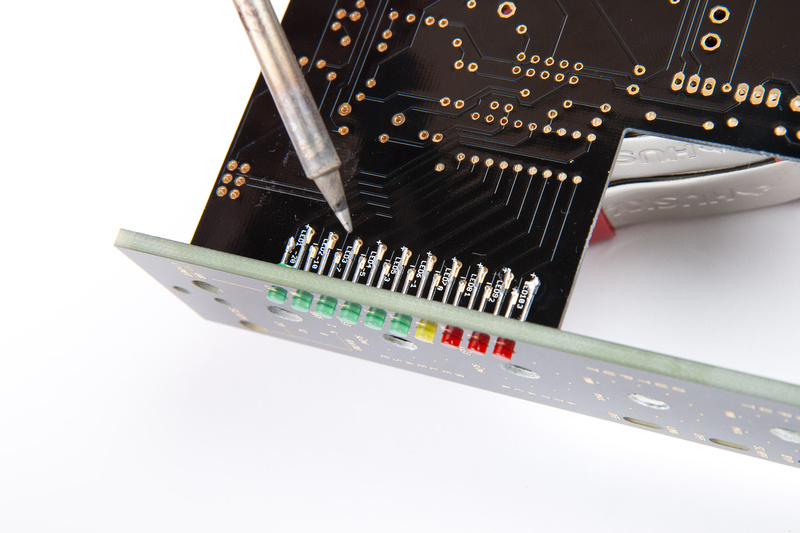

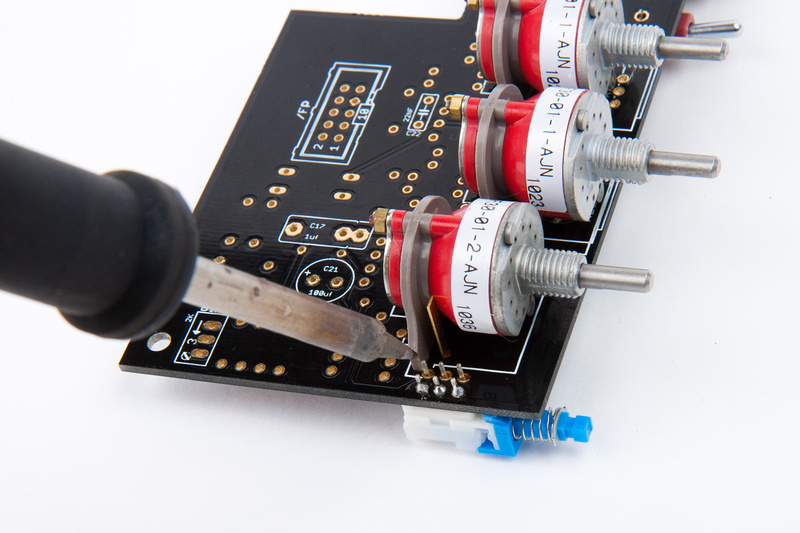

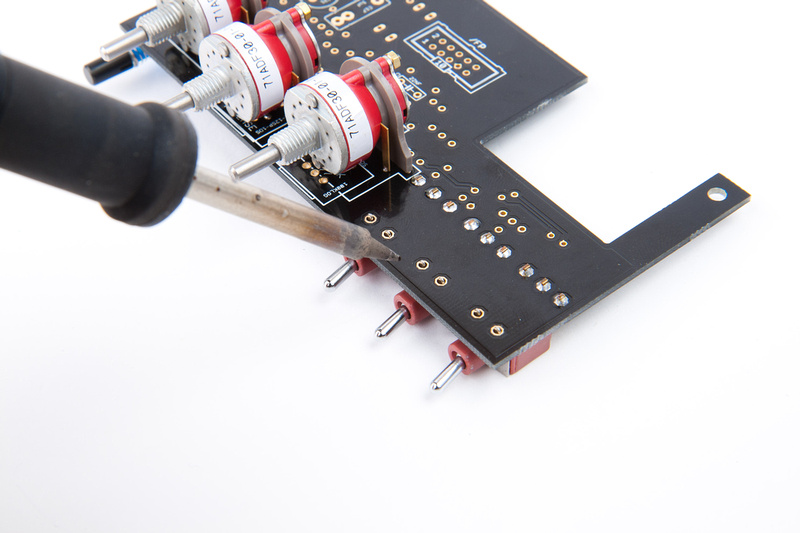

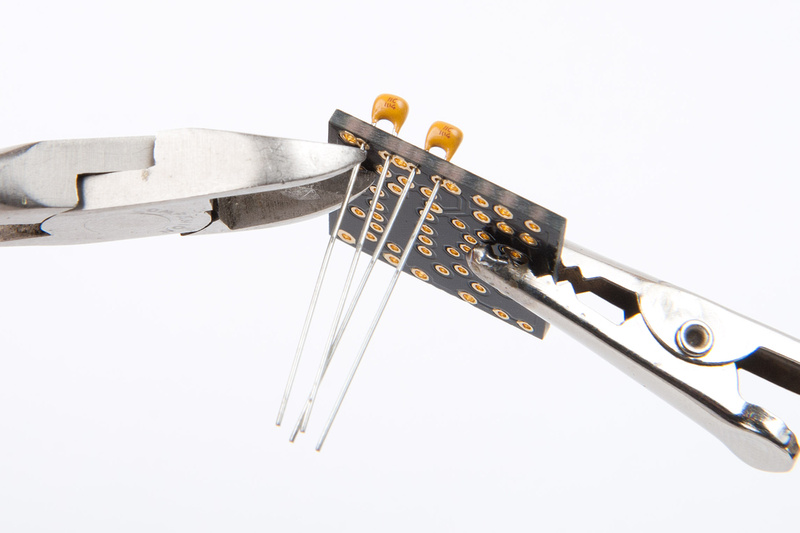

I used a clamp to help me position the end LED's for soldering.

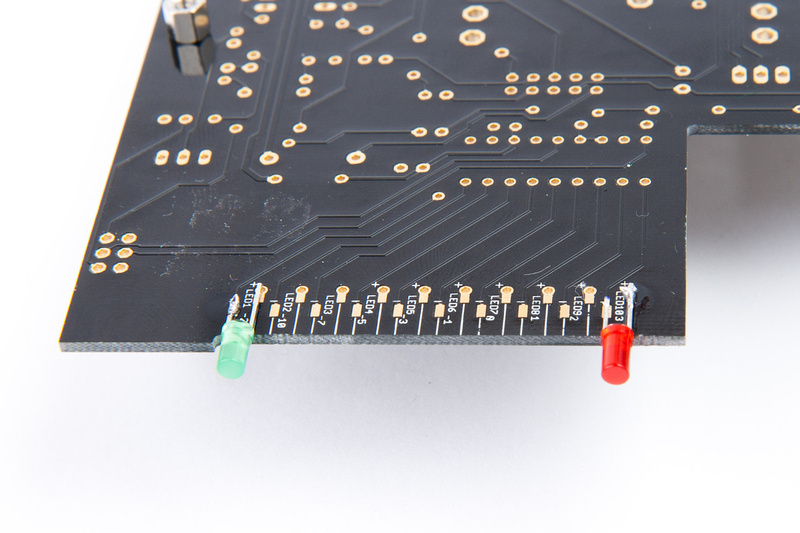

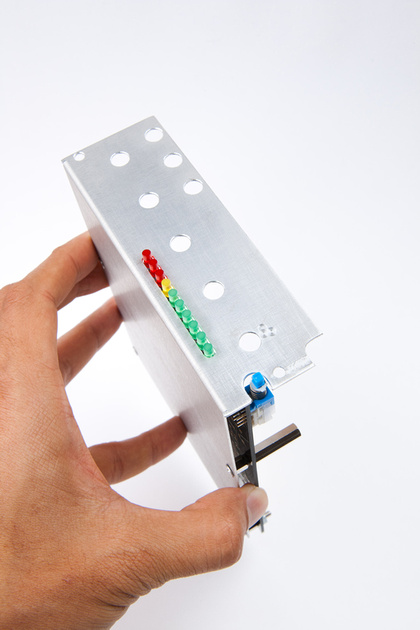

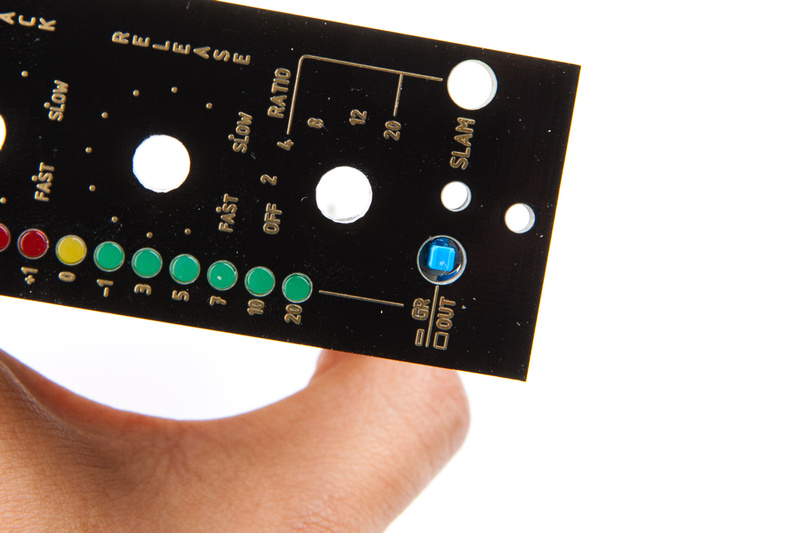

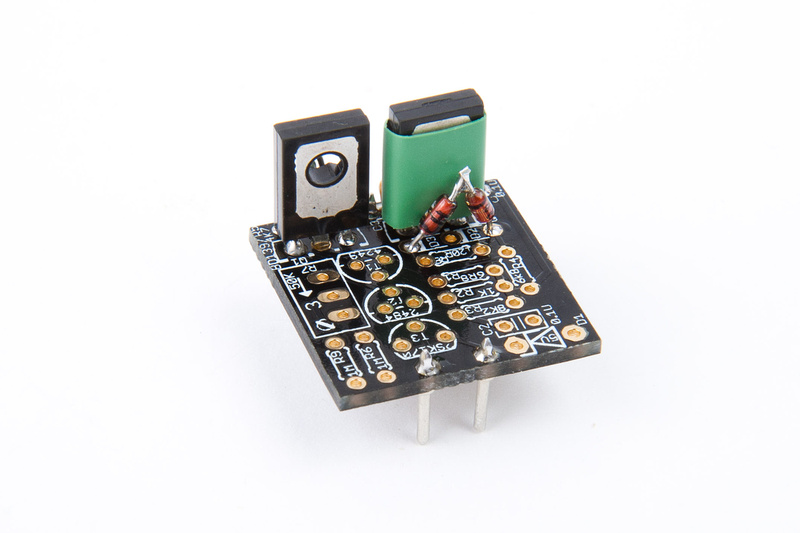

and, LED's installed.

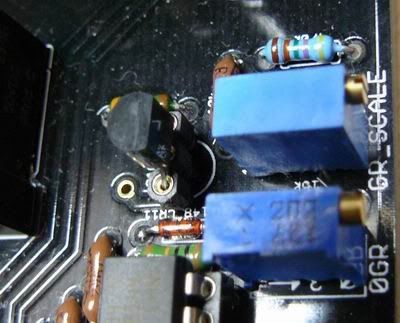

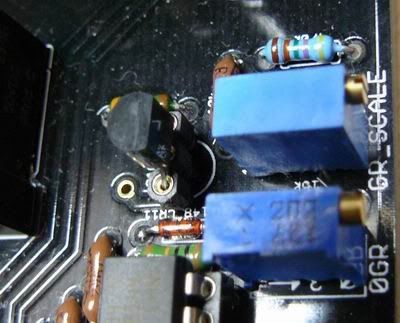

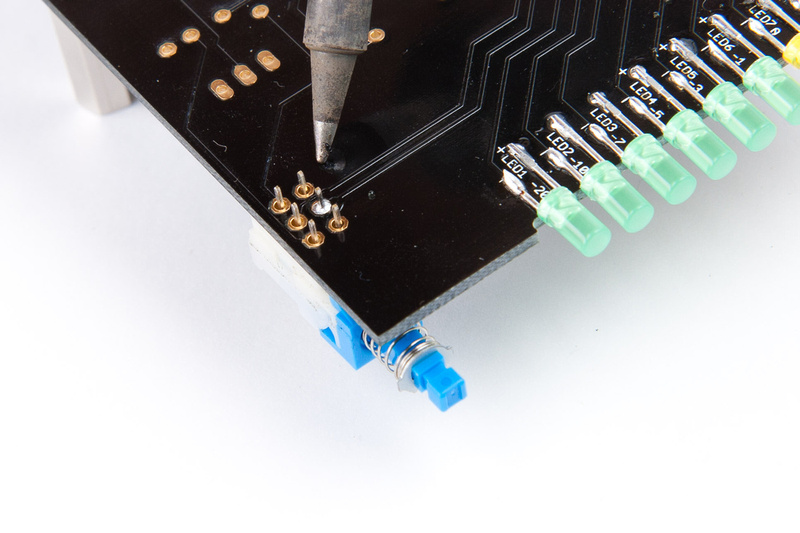

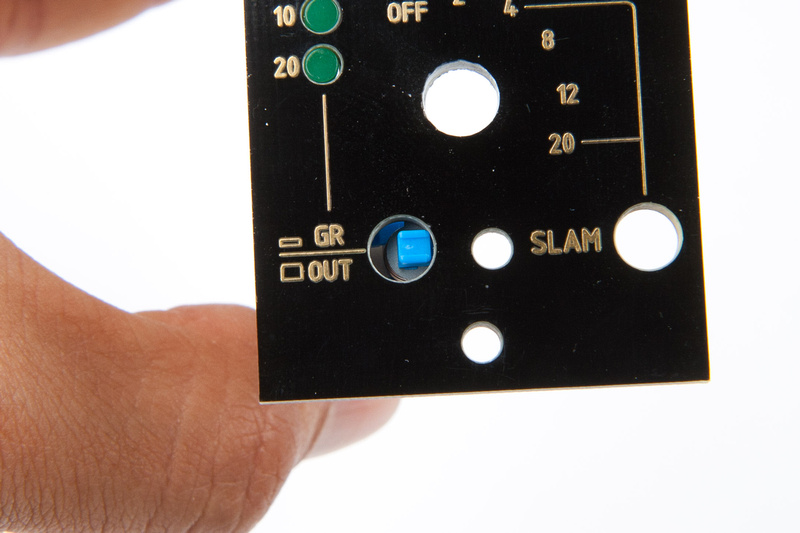

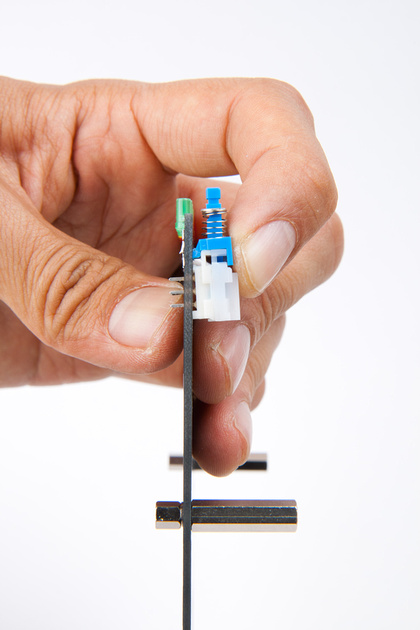

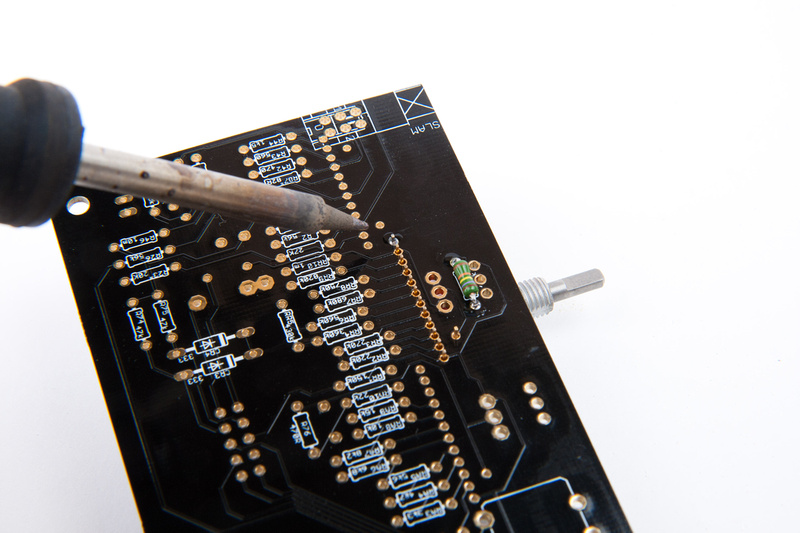

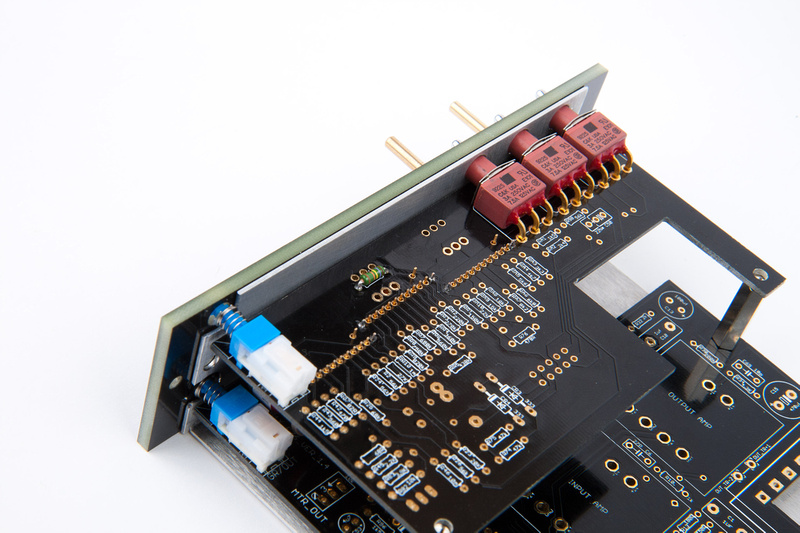

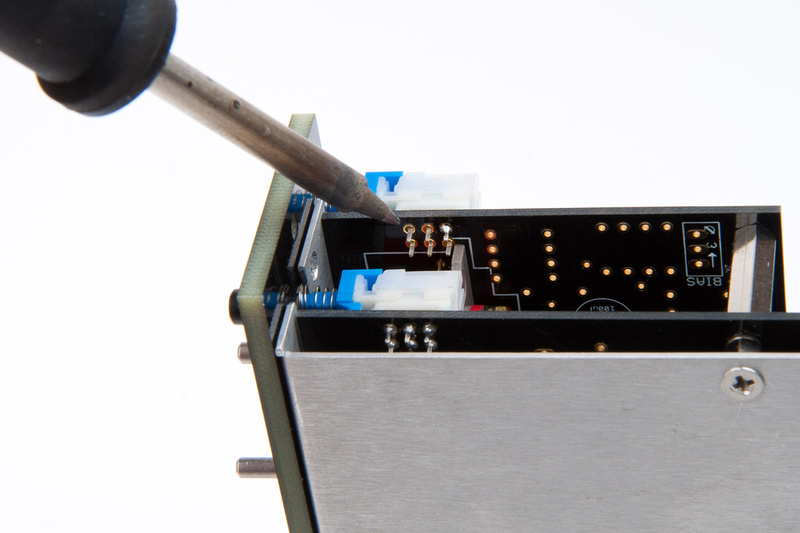

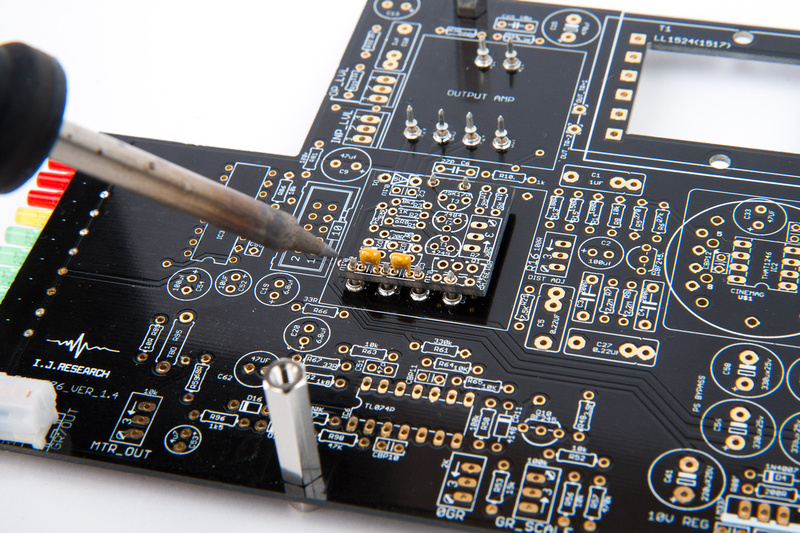

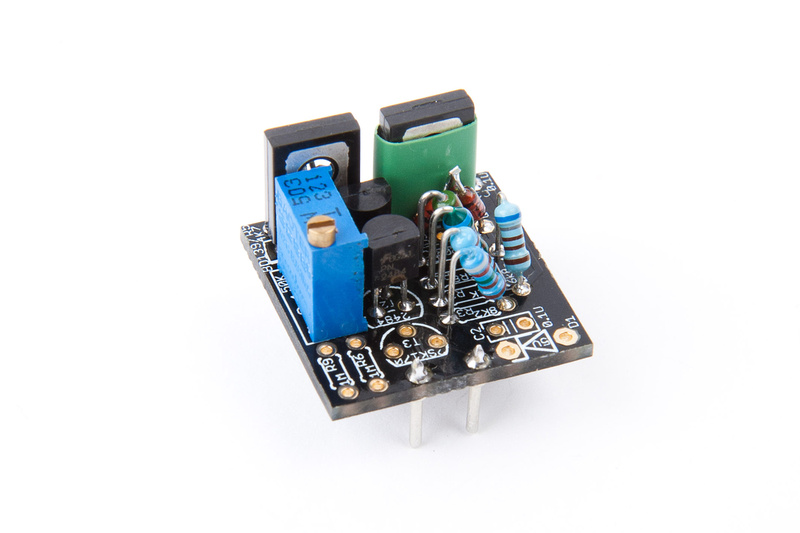

Next, I install my metering GR/output switch making sure to ONLY solder 1 pin.

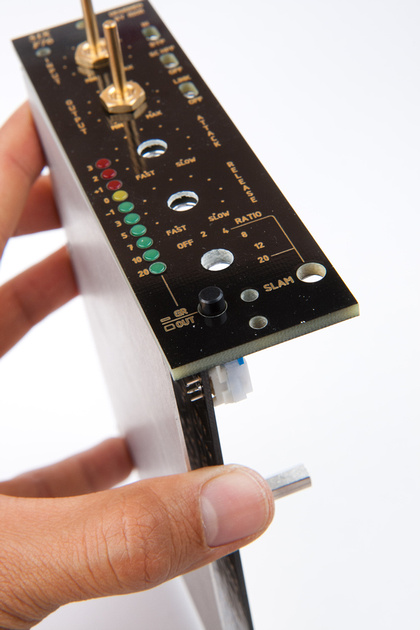

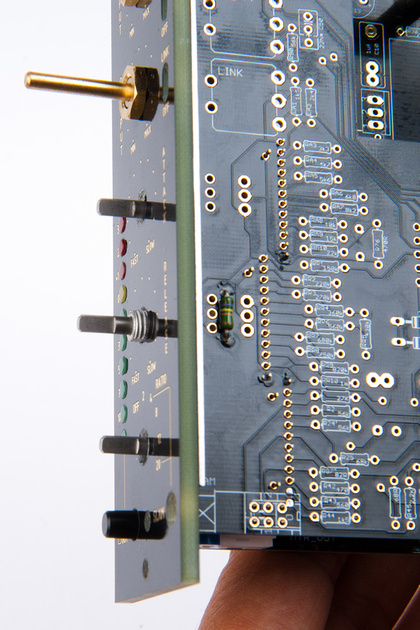

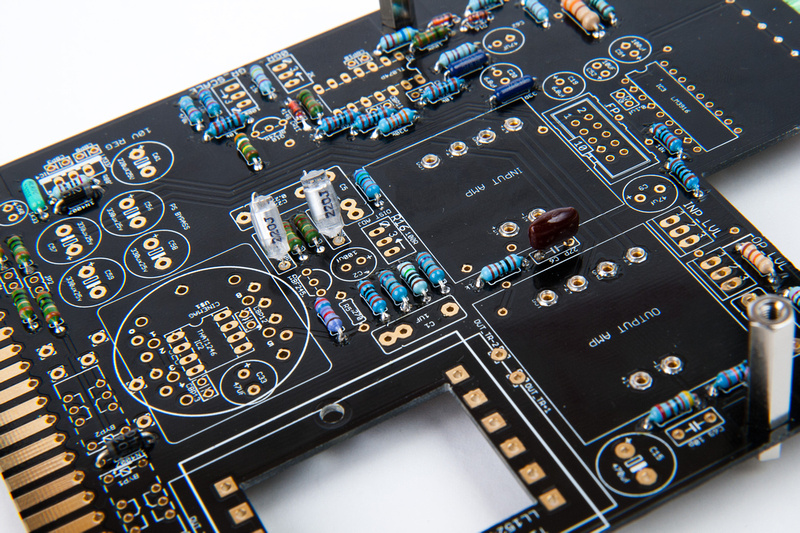

Then, I re-assemble to see how things are lining up.

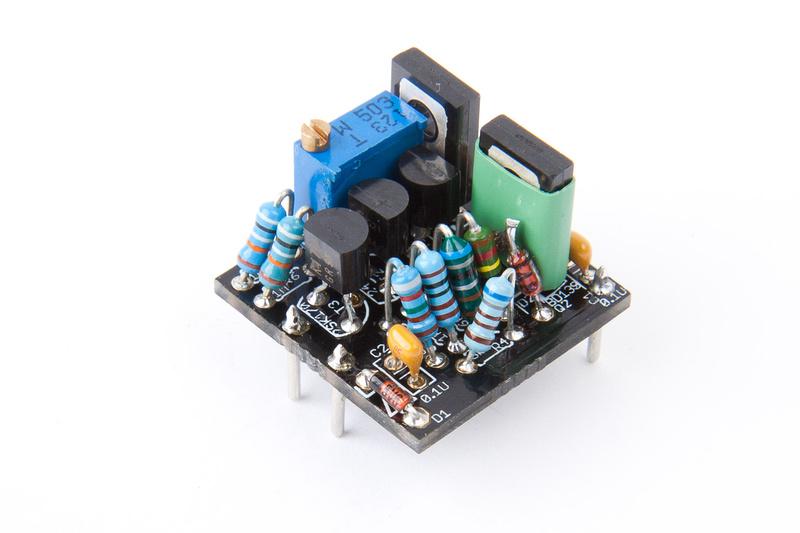

And, they are lining up poorly.

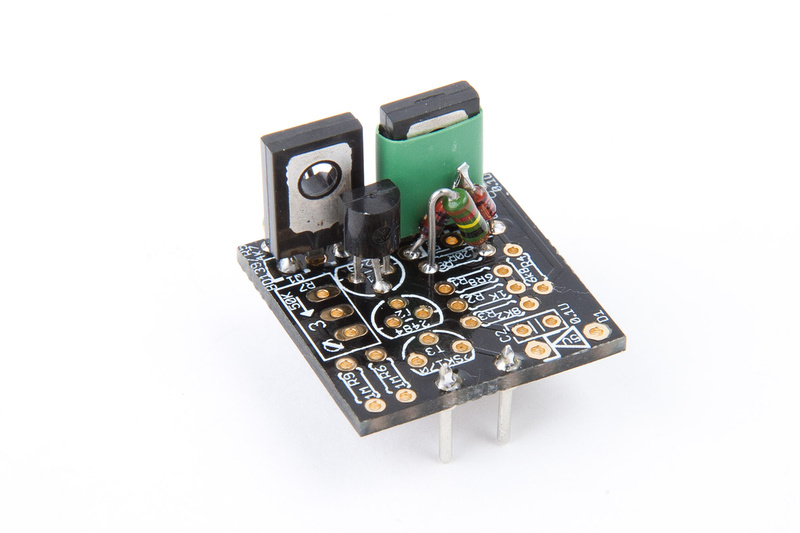

It seems the LED's are pushing the main PCB upwards a bit creating a bend, and causing the switch to move upward. The LED's are all soldered in and I do not foresee them moving easily, so I decide to modify the switch to fit better.

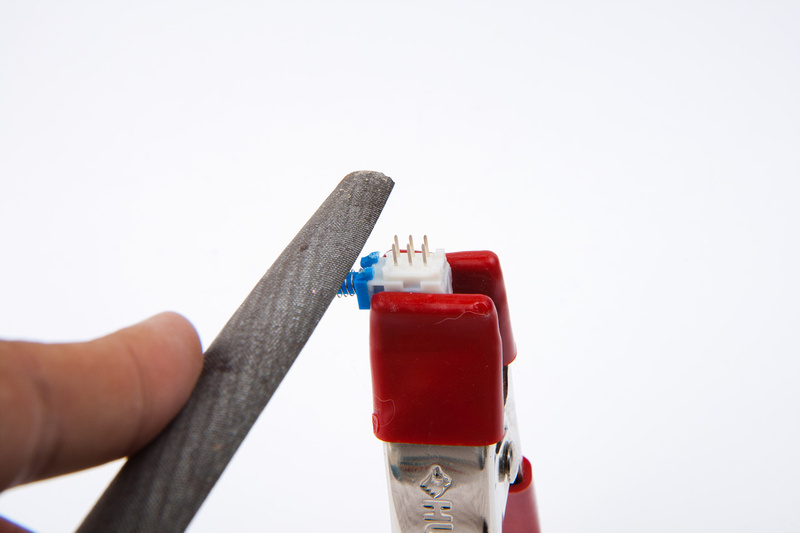

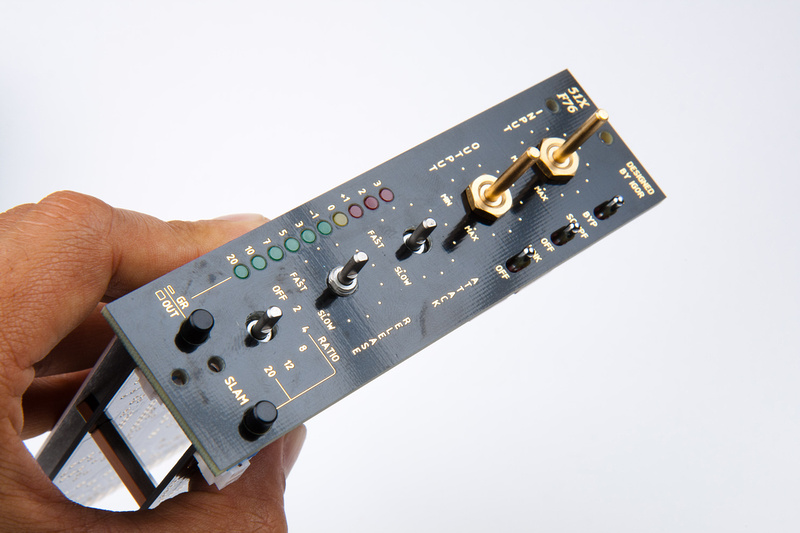

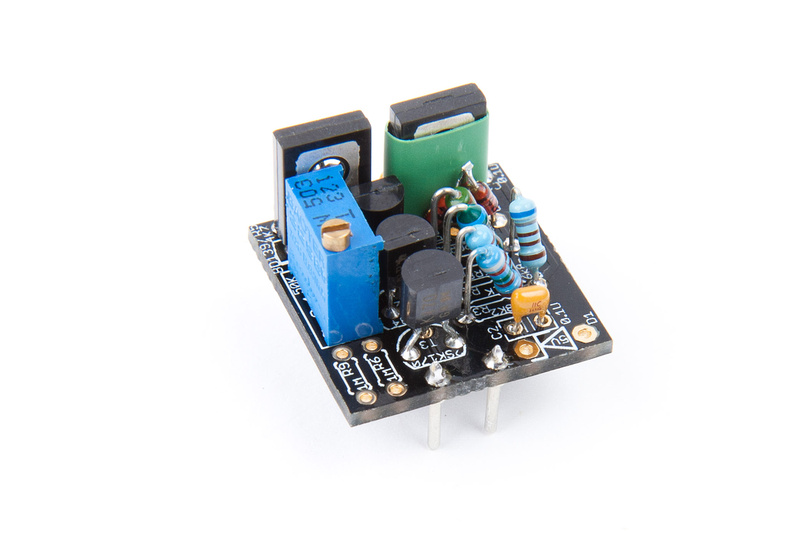

I figure I should try to compensate and make an adjustment so the switch is not installed under strain. I remove the switch (luckily, I only soldered one lug) and file the front mounting tabs.

now the switch will mount in a compensated position.

I re-mount soldering again, only one lug to verify.

And, my alignment is now reasonable.

I install the external button to confirm

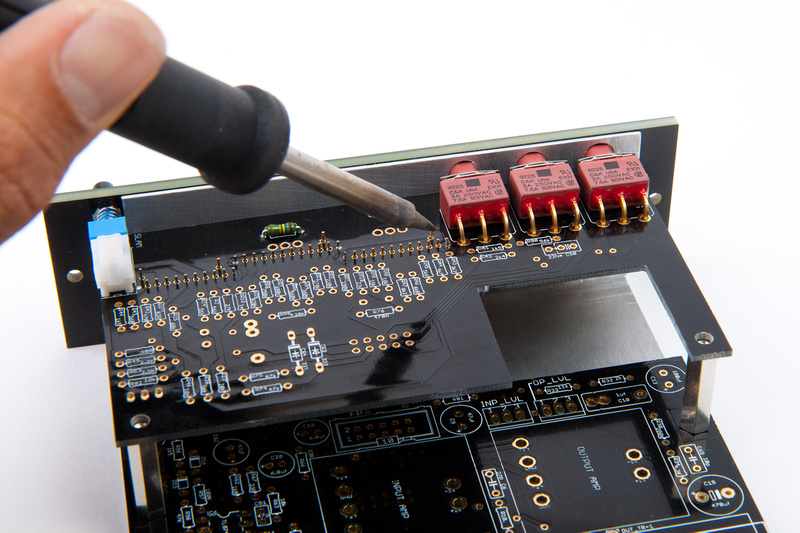

And then, when I am satisfied that the switch position is good to go, I solder the 3 accessible lugs in place.

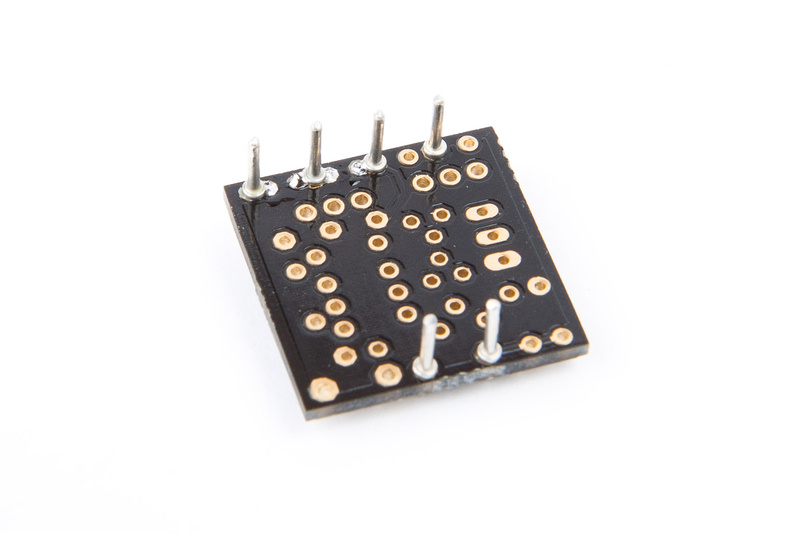

Then, I disassemble and solder the remaining lugs.

Here I am for now. . . slow, but steady gets the job done right I hope. . . next, I will align the grayhills on the upper PCB.