Hi all.

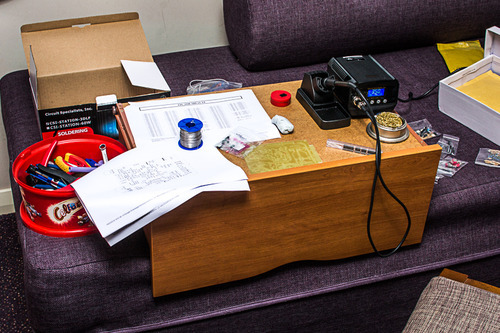

So I got time in my hotel room to solder... I'm serious:

;D ;D ;D ;D ;D ;D ;D ;D

Please note the fan and open window to make sure no unnecessary fire alarms went off... I DID confirm this with staff first.

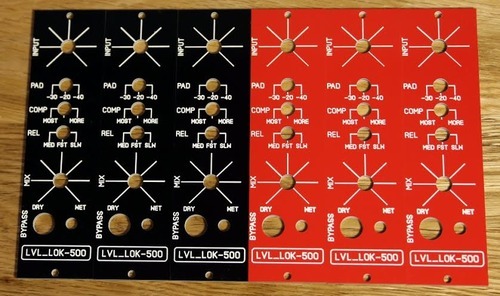

ANYWAY. The CNC version Marek will be making has been verified...

So hopefully he can start sending these out to all you GOOD GOOD people! I do however think I have messed up the switching diagram I posted before so I'll try and correct that before 2015!

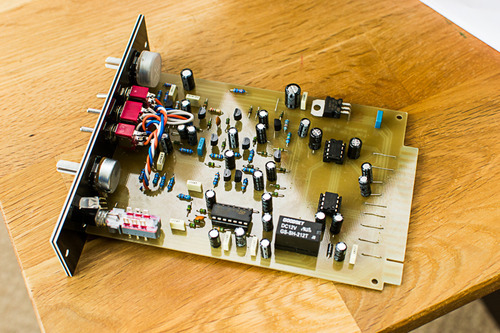

Couple of tips with Mareks boards:

- They are really nicely made and drilled. Enjoy.

- They come pre tinned, which is nice, but it also means you have to be REALLY careful and not bridge anything. I made a couple of mistakes and I'm usually quite neat (may be it was the hotel room!?

)

I have not got time to check for sled-compatibility yet but will do so when I get chance. I have not had any issues yet with the pot mounted front panel but at the same time I'm not really one to yank or rush unit removals. I'll probably want to eventually mount them on sleds (I'll end up with a totally non matched pair

) so it makes sense to try it.

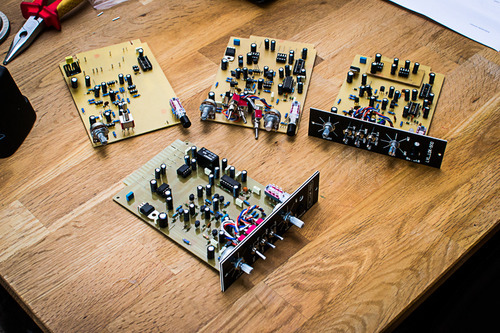

I suppose at this point a family photo may be nice?

Evolution of a LVL_LOK?

Ian.

;D ;D ;D