Echo North

Well-known member

Does the DI work?

Houstnwehavuhoh said:Yes the DI works

FattyMA4 said:Hey Mike,

I just plugged my Coles 4038 in, and did some A/B'ing, and there is DEFINITELY not the low end in my Bronze, like there should be.

Could there be low end from the DI, but not from the Mic Input?

Is that a possibility? At all?

I think it runs through the same thing, once you get to that certain point....

I'm think I'm just gonna send it out to ya.

How does one go about doing such a thing?

darnell said:Hey all.

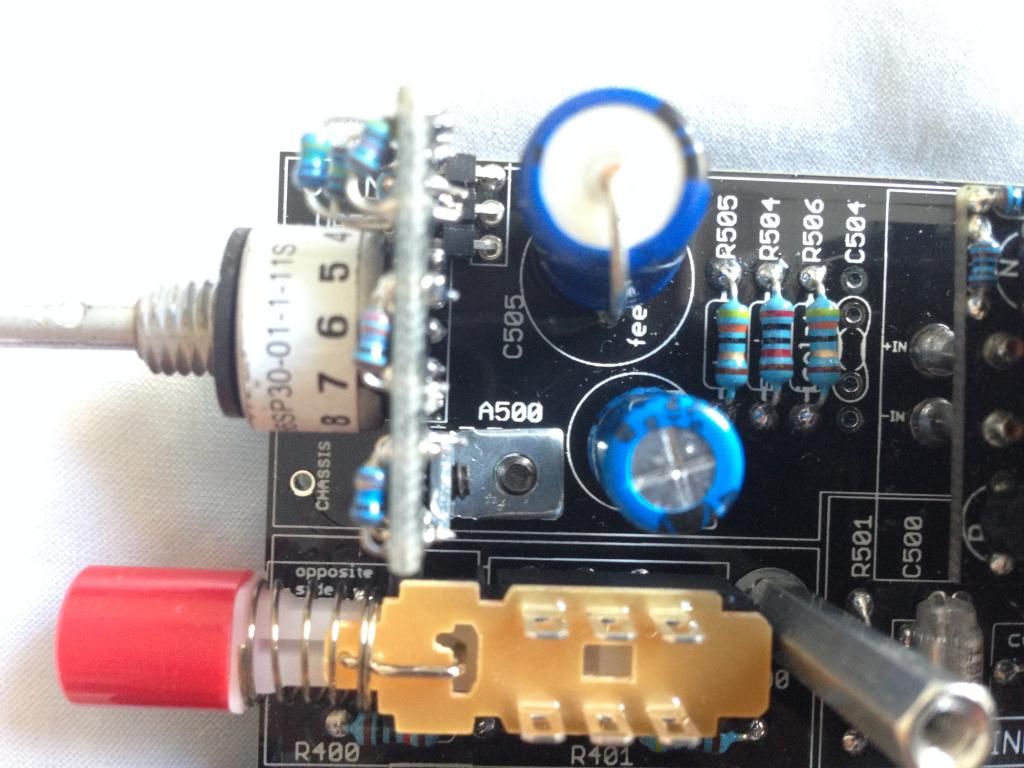

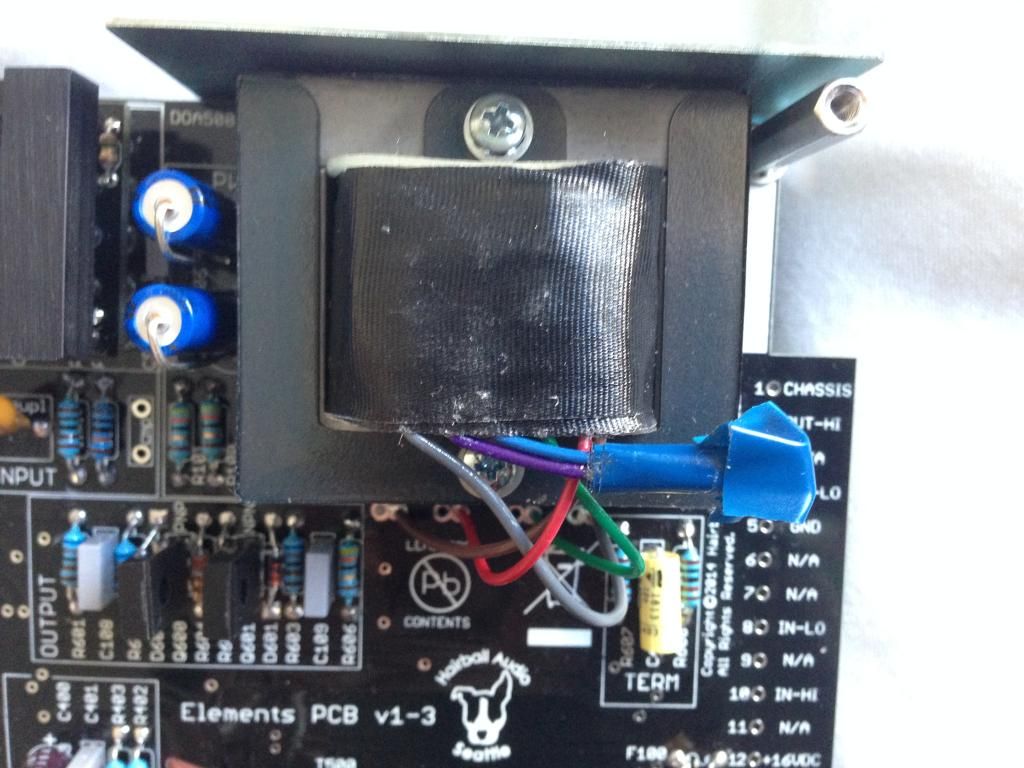

I bought 4 Silver kits hoping I could build a specific Eisen API I bought on this forum when i first started recording. It's really simple, and I've always prefered the pre to other APIs (512 and VP26/25). So I finally got my Cinemag 75101APC inputs in yesterday. Heated up the iron, made a coffee, and opened the transformer box and my got out my 99% finished Silver kit. Went to put the Cinemag on the PCB where the canister type tranny goes...........

And it doesn't fit....................

I guess the pin spacing on the Cinemag is a little smaller than whatever Hairball is sending with the Bronze, ect. So it's not possible to just bend the pins out from the canister. I believe it's the same pin spacing as the EA2622 as well. So if you grabbed the Silver kit trying to use canister type input trannies from Cinemag or EA, it looks like they are not drop in.

After some creative mounting (double sided tape and flying leads) i got it wired up and working. Haven't compared to my original Eisen yet, but it's passing signal and everything seems to be working. I'll report back with some observations once i get the Silver and Eisen in the same room.

Any ideas on mounting the next Silvers input tranny? I did double sided tape on this one and flipped the Input canister so the pins face up. The tape adds about a .08 inch. And now those upward facing pins are a little too close to mount the other metal cover.

Lemme know if you have ideas.

D.

darnell said:Hey Mike. Thanks for replying. Love the Silver kit so far. Really clean layout and great labeling.

Ill prob try the board mounting idea you suggested. I bought 2 inputs from Cinemag, so i can try it with the second one.

I still have 2 more Silver kits that i need to get transformers for, so i may inquire about a custom can for the last 2. What pin spacing are you using your complete kit transformers? If its not crazy expensive, i will prob just suck it up and get exact fit transformers from cinemag.

Thanks.

D.

JustDavid said:I built a copper and bronze pre-amp, both builds went smoothly, the bronze is great but I've got an issue with the copper. The copper unit is passing signal, both on DI and Mic input, but the stepped gain isn't affecting the input gain level. In other words, regardless if the step of the gain stage, the preamp output level is set only by the output pot. I checked back to make sure all solder points were solid and that I didn't miss any. All resistor values look right. Anything else that may be causing this other than the greyhill assembly?

Hairball Audio said:JustDavid said:I built a copper and bronze pre-amp, both builds went smoothly, the bronze is great but I've got an issue with the copper. The copper unit is passing signal, both on DI and Mic input, but the stepped gain isn't affecting the input gain level. In other words, regardless if the step of the gain stage, the preamp output level is set only by the output pot. I checked back to make sure all solder points were solid and that I didn't miss any. All resistor values look right. Anything else that may be causing this other than the greyhill assembly?

I would reflow all of the solder joints (Grayhill and Resistor) and make sure none of them are touching.

JustDavid said:Hairball Audio said:JustDavid said:I built a copper and bronze pre-amp, both builds went smoothly, the bronze is great but I've got an issue with the copper. The copper unit is passing signal, both on DI and Mic input, but the stepped gain isn't affecting the input gain level. In other words, regardless if the step of the gain stage, the preamp output level is set only by the output pot. I checked back to make sure all solder points were solid and that I didn't miss any. All resistor values look right. Anything else that may be causing this other than the greyhill assembly?

I would reflow all of the solder joints (Grayhill and Resistor) and make sure none of them are touching.

I just popped it apart and reflowed , nothing appears to be touching. still no change.

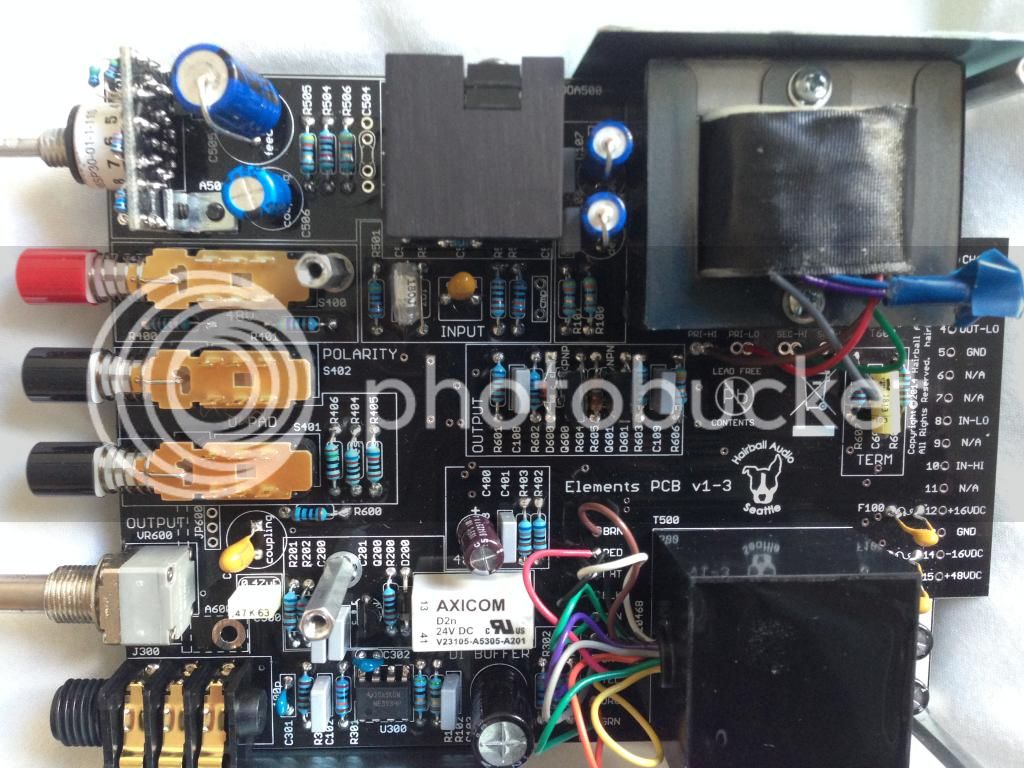

JustDavid said:So now that my Copper is up and running, flawlessly might I add, I found some issues with my Bronze pre. Although at first it seemed to be fine I noticed some small issues.

1) When the DI is engaged, there is a high pitch ringing noise, and an intermittent chirp/squeal, almost like RF interference or something. It is apparent at all gain stages and output volumes (at various amplitudes). At first I thought it was noisy electronics in the instruments, but the issue is not happening in my copper. Engaging the pad helps the matter slightly but doesn't really resolve the issue.

2) when in DI and Mic mode, With the Grayhill fully clockwise, and the pad engaged, the last 1/8th turn "clicks" and then it makes a equaling noise. But this only happens with the grayhill fully counter clockwise…not that I would ever probably need to max this thing out like that, it would seem to be an indication of something not being quite right.

3) With a mic connected, the final position of the Grayhill decreases gain, with slight distortion. normal?

The bronze seems to have more "noise" than the copper, perhaps this is normal.

Most these observations where made without a mic/guitar/etc being plugged in, just the sound of the module itself. My primary issue is with the DI ringing/squeal. I plan on reflowing some of the gray hill points to see if that fixes the final stepped gain issue. Any thoughts would be appreciated. I would rather try to trouble shoot this thing so I can learn something in the process.

martinswain said:Hi Mike,

I'm having issues with my builds as well. Apologies if this has been posted multiple times, but I'm having some strange things happening with my Bronze and Copper modules. I'll start with the Bronze because it's minor in comparison to the Copper.

Like the user who posted above, the Grayhill switch doesn't increase gain until I switch it to the last notch position, where there's a massive increase in gain. In other words, none of the other gain positions do anything to increase or decrease gain. Any ideas what this could be?

martinswain said:As for my Copper module, I'm getting some weird distortion. At first I thought it might've been the output transistors being overheated and creating a short, as I foolishly put them in the wrong way (the right slots, just facing the opposite direction to what they should've been). I bought some new transistors and soldered them in, but to no avail. This led me to think that it might've been a coupling capacitor (again I felt that I'd overheated it). I've replaced this capacitor and still no change to the signal. **note that although the coupling capacitor I've replaced is physically smaller and radial rather than axial, it is still the same value and brand as the one in the bill of materials.