Ptownkid

Well-known member

Let me check, i should have some around that i won't use now that I have a cnc. Also, you can get pulsar transfer film from rp-electronics.com in canada.

Matador said:to be honest, you can get real PCB's made for less than $1 per sq. in., with real solder masks and silkscreens and fully plated through-holes. The chemicals alone cost more than that!

Ptownkid said:Let me check, i should have some around that i won't use now that I have a cnc. Also, you can get pulsar transfer film from rp-electronics.com in canada.

Ptownkid said:They have an iron on transfer film...if you can, return the ferric chloride and buy some ammonium persulfate instead

Insomniaclown said:Plus, I think there will be a sense of satisfaction that comes along with going DIY all the way.

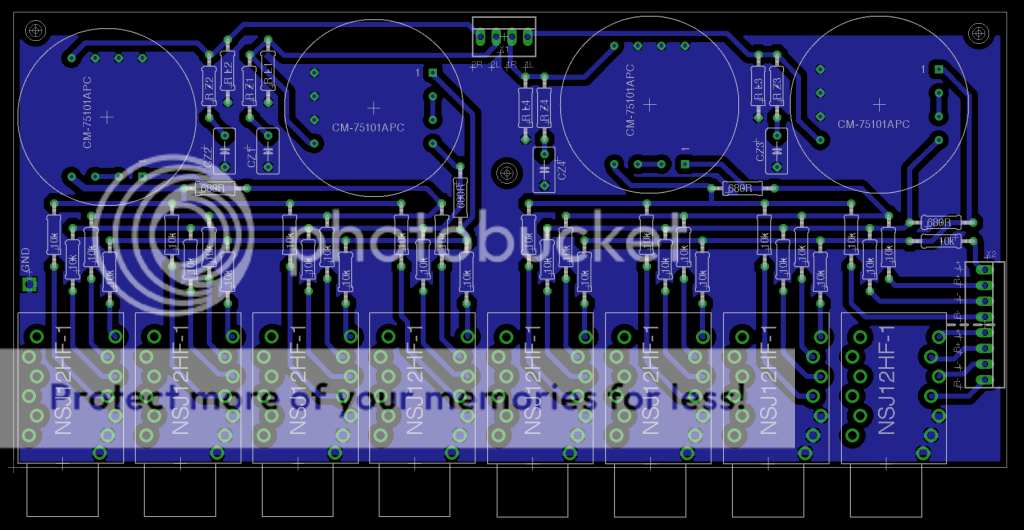

ej_whyte said:Thats cool dont worry, i've been busy with exams etc and i'm working on the 8 channel version at the mo.

Cheers

I like 10 mil clearance on pins, which is 0.254mm. Take the largest tolerance for the pin diameter (it should be 0.64 +- some small number), and add 0.254mm. This should be the finished hole size (it's the drill diameter plus twice the plating thickness on the holes).ej_whyte said:The cinemag website says the pins are 0.64mm (http://cinemag.biz/mic_input/cm-75101APC-machine_drawings.html) and at the mo i have 0.8mm holes for them, is that ok or do they need to be a bit bigger?

Cheers

3nity said:One tip on my experiences..

Always use bigger or huge pads..small ones are hard to solder...specially on resistors and caps..i do them all over the place now!!

lernith said:I'm wondering if the ground loops surrounding the Neutrik jacks are a problem? They're small but numerous. I suppose the answer is "it depends, just try it both ways". Etch it as is, then see if scraping a break between a 10k resistor per Neutrik jack and the buss makes a difference.

Nobody mentioned the ground loops, which makes me think they don't matter in this instance. Could someone explain why, or is this just a vague thing you get an eye for?

Enter your email address to join: