critterkllr

Well-known member

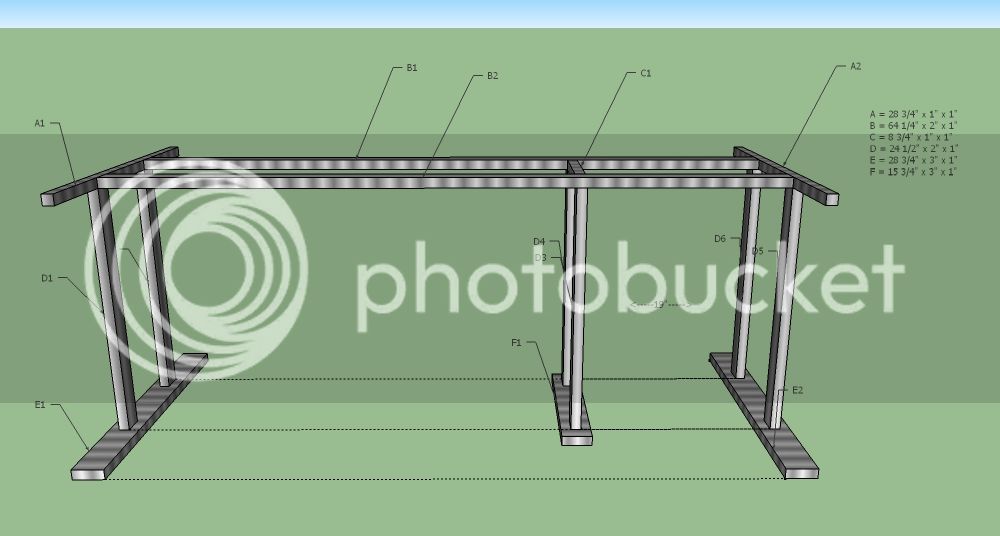

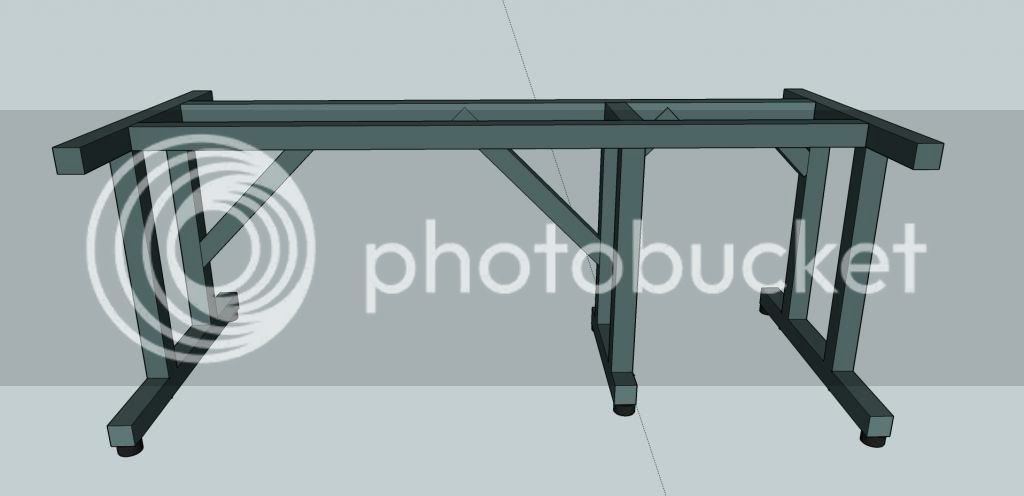

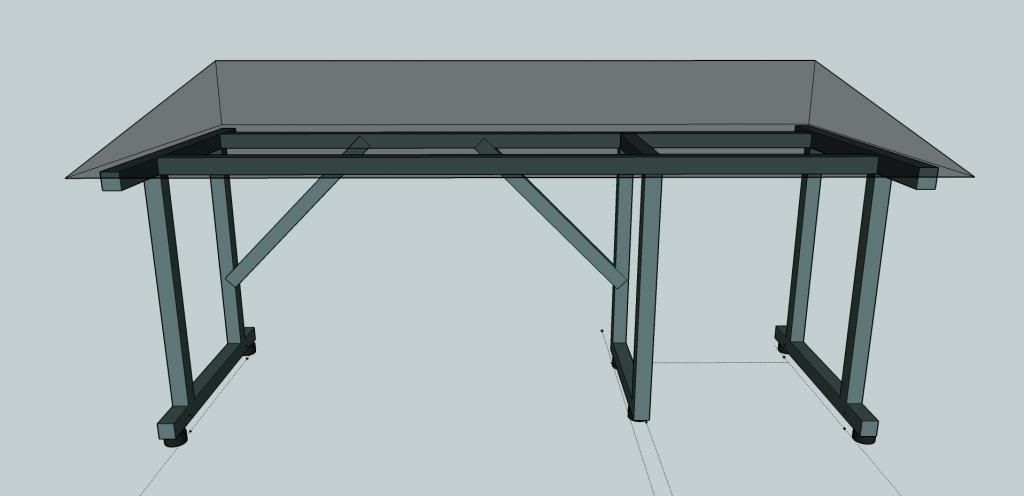

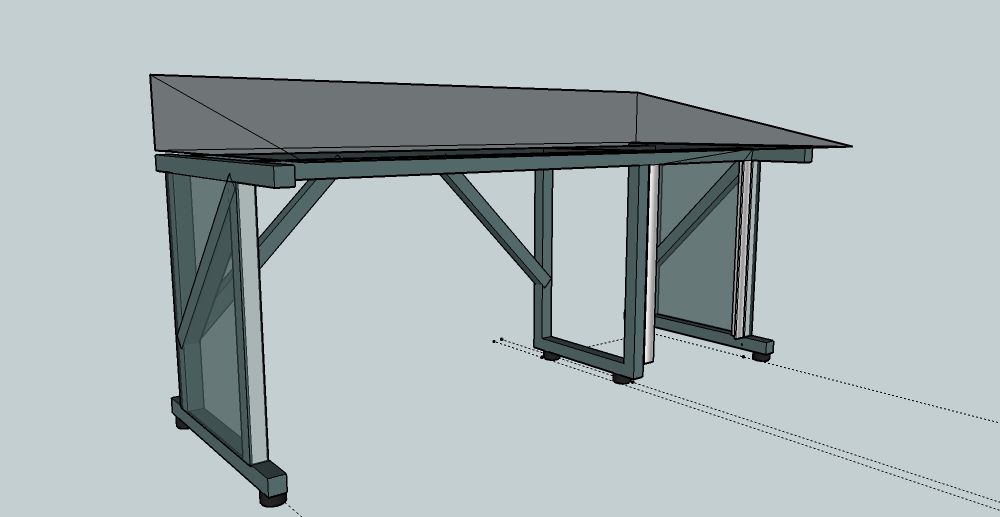

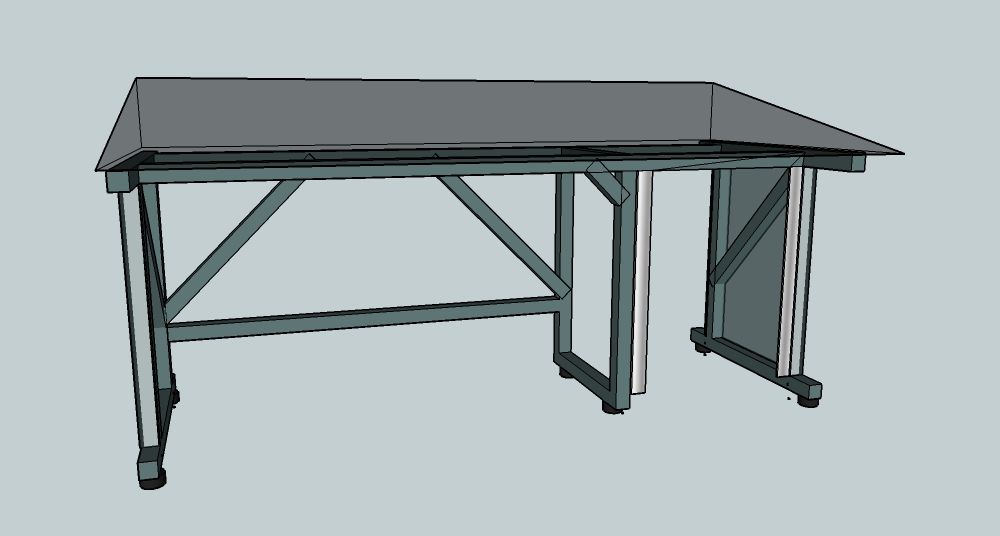

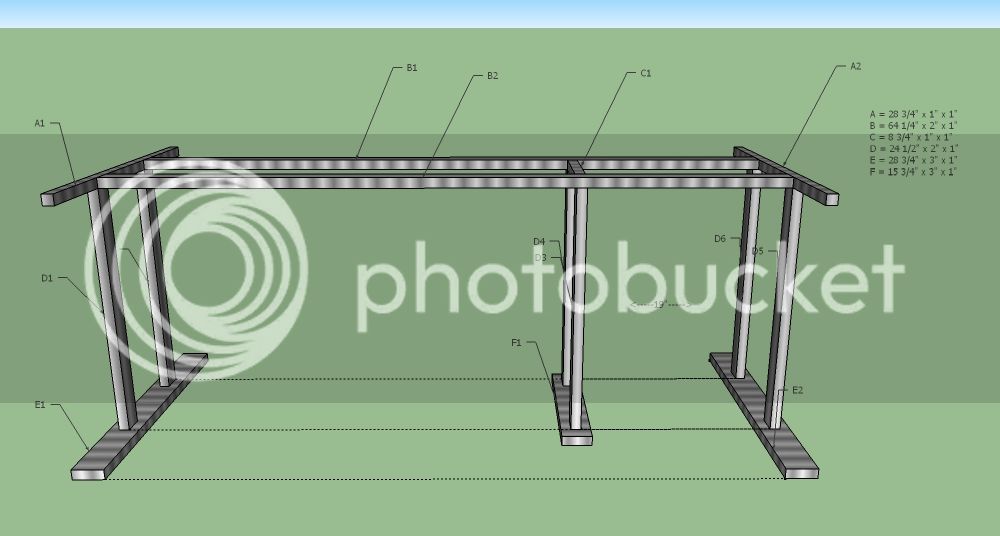

I'm planning on having a stand made for my console. I was wondering if I could get some advice on the type of metal I should use and if the construction looks solid. The console currently weighs 350 lbs, but I may add some traffos to it. I don't know how much that would bring the weight up to. I am planning on having somebody weld all of the pieces together. The stand will be painted to match the console. It will also include a 19" rack to hold a couple power supplies.

With the exception of the feet, I wanted to use metal tubing. Any advice on the type of metal and thickness I will need? I had estimated for A513 steel at 11 GA (.120 wall). Is this overkill? Something like 14 or 16 GA would bring the price and weight down. Aluminum would be nice for the weight, but I want it to handle the weight and be able to paint it without issues. I have absolutely zero metal working experience, so any input would be appreciated!

Here's a model I made using Sketchup:

With the exception of the feet, I wanted to use metal tubing. Any advice on the type of metal and thickness I will need? I had estimated for A513 steel at 11 GA (.120 wall). Is this overkill? Something like 14 or 16 GA would bring the price and weight down. Aluminum would be nice for the weight, but I want it to handle the weight and be able to paint it without issues. I have absolutely zero metal working experience, so any input would be appreciated!

Here's a model I made using Sketchup: