matriachamplification said:

The MK3 screening looks really slick.

I will order a Fischer Cassette for reference and begin designing the EZTube Modules with the new MK3 Screening.

I just went out to the garage and came across an old EZTubeMixer Helios 69 front panel from one of my early mixers. Looking at it made me suddenly realise I need to add a couple of caveats to what I said in my last post about using the Mark 3 mechanics in an EZTubeMixer based design.

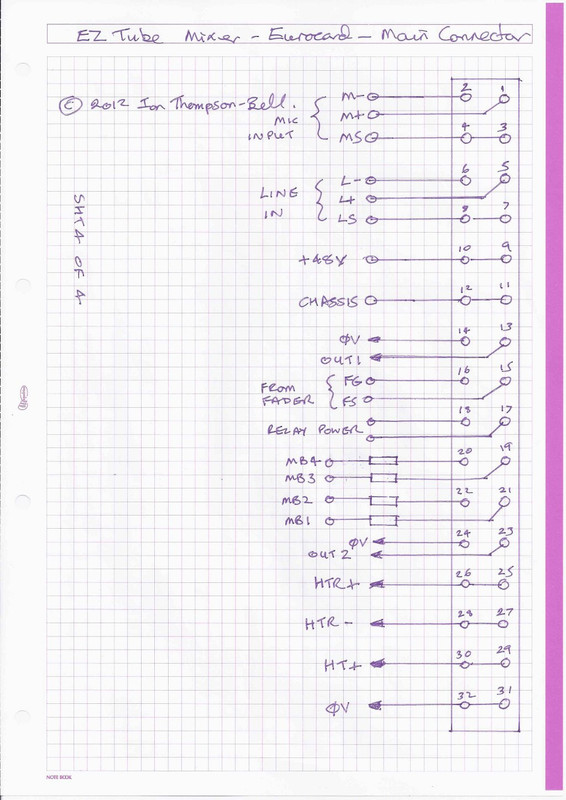

Bottom line is this will really only work properly only if you are using 3U high modules. This is for two reasons. First the 3U PCB is designed to fit into 3U card guide rails which give the module the necessary support and significantly eases locating the 32 way connector in the backplane mating half. The second reason is that you can attach the rear of the steel screening plate to the 32 way connectors using pillars.

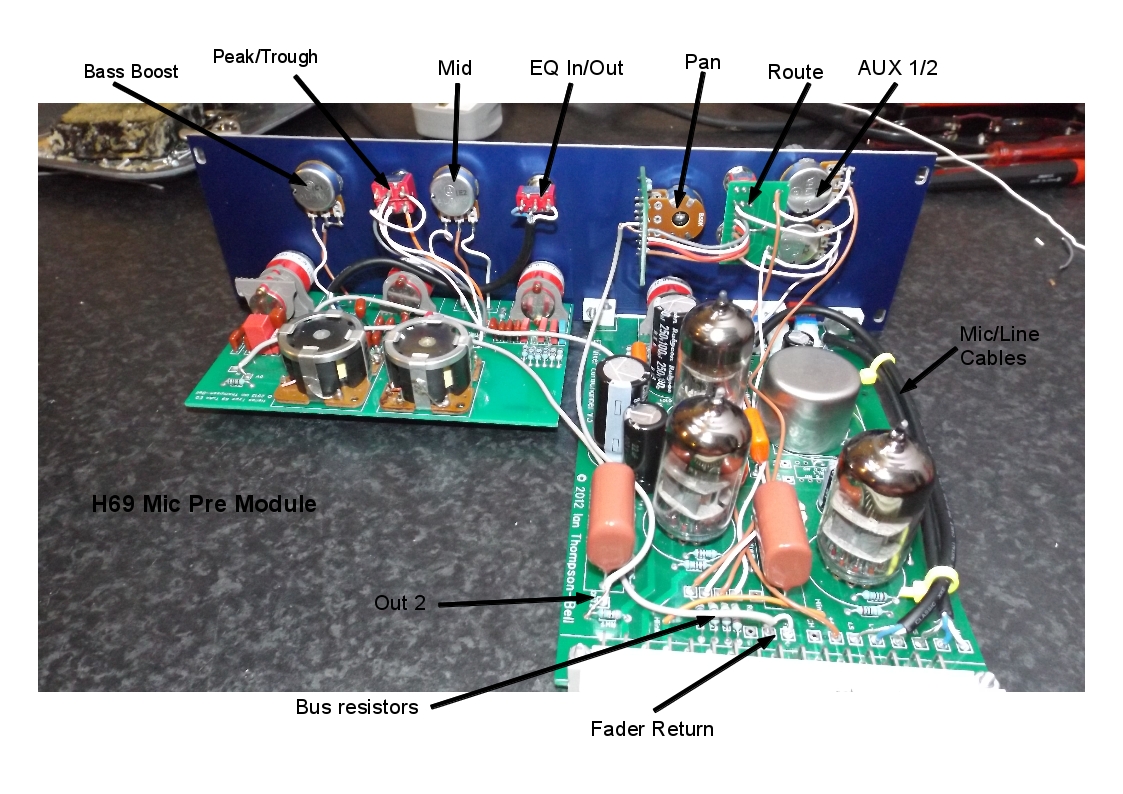

Any other option has unresolved problems. For instance, it you want to build 6U high EZTubeMixer modules in the normal way using two separate PCBs like this Helios 69 channel:

then you can immediately see the problems:

1. The bottom PCB (left in the pic) does not necessarily align with the bottom card guide.

2. The bottom PCB is not as deep as the top one so does not give the same support

3. There is no place on the bottom PCB for the pillars needed to attach the steel screening sheet.

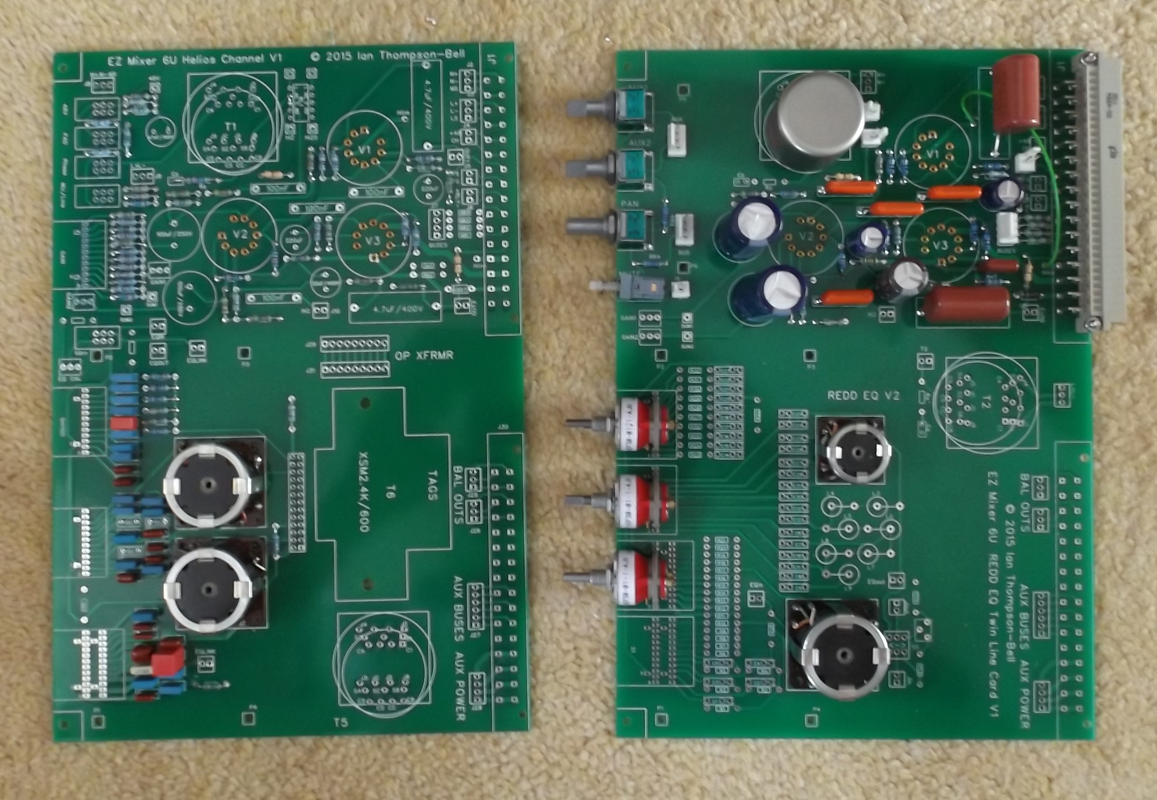

The obvious solution to these problems is to use a 6U PCB and that is initially the direction the 2nd generation EZTubeMixer was going. But it meant designing a new 6U PCB for each EQ. And every time a customer wanted something different in a module it would again require a new 6U design. Also at this time, lots of people were talking about line input mixers so the same boards would be required without the mic pres which would be another 3 PCBs to design. it looked like I would have a lot of types of PCB many of which might rarely be used. Nevertheless a couple of 6U cards were designed:

By this time, 6U Fischer cassettes were becoming very expensive, the Mark 3 half width idea was born so the mechanics really needed a complete review. I wanted to have:

1. A low cost 3U/6U mechanical system that was robust, space efficient and provided adequate screening

2. A minimum number of different 6U PCBs along with a decoupled means of customising modules to clients requirements

Easy to say but it took a lot of time and effort to arrive at the current Mark 3 scheme. The mechanical solution I have already described. The decoupled means of customising modules is achieved by mounting a separate PCB behind the front panel.

ALL the front panel controls are soldered directly to this PCB and the assembly is mounted to the front panel using the controls themselves. This means the main 6U PCB can have a standard EQ built in along with input and output transformers and a TLA. The only thing that distinguishes one customers module from another is the way these elements are connected together and the arrangement of controls on the front panel. All that is taken care of by the relatively small front panel PCB. There is a lot more detail on the development process in the Mark3 blog.

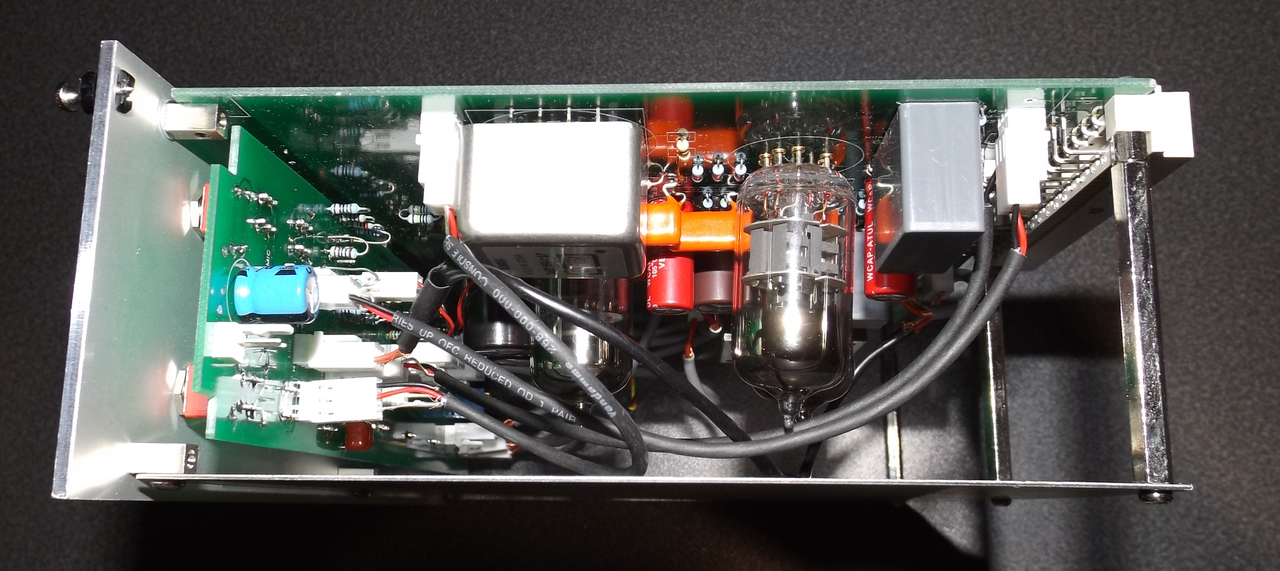

The first real test of the new scheme came in the last EZTubeMixer I built which acted as a vehicle for all the main Mark 3 improvements except the narrow width. For this mixer I designed a 6U TLA with mic input transformer, custom output transformer and a version of the REDD EQ. This PCB also used the new pin out for the 32 way connector and used the new Mark 3 backplane and I am pleased to say it works extremely well. Here is a pic of the 6U module from the top showing how the three pillars at the back attach to the steel screening plate:

I hope this has not confused you too much. The safest approach is to build an EZTubeMixer the old fashioned way with no mechanics at all. If you want the benefits of the Mark3 mechanics without hassles then you need to restrict yourself to 3U modules or use 3U Fischer cassettes

Cheers

Ian