I have been asked to make a Fairchild 627 equaliser, this is apparently a very rare beast (only 5 in existence?) so I will make it as a project on the forum as a record for the future. According to legend, one was used to master the Beatles She Loves You single in the USA.

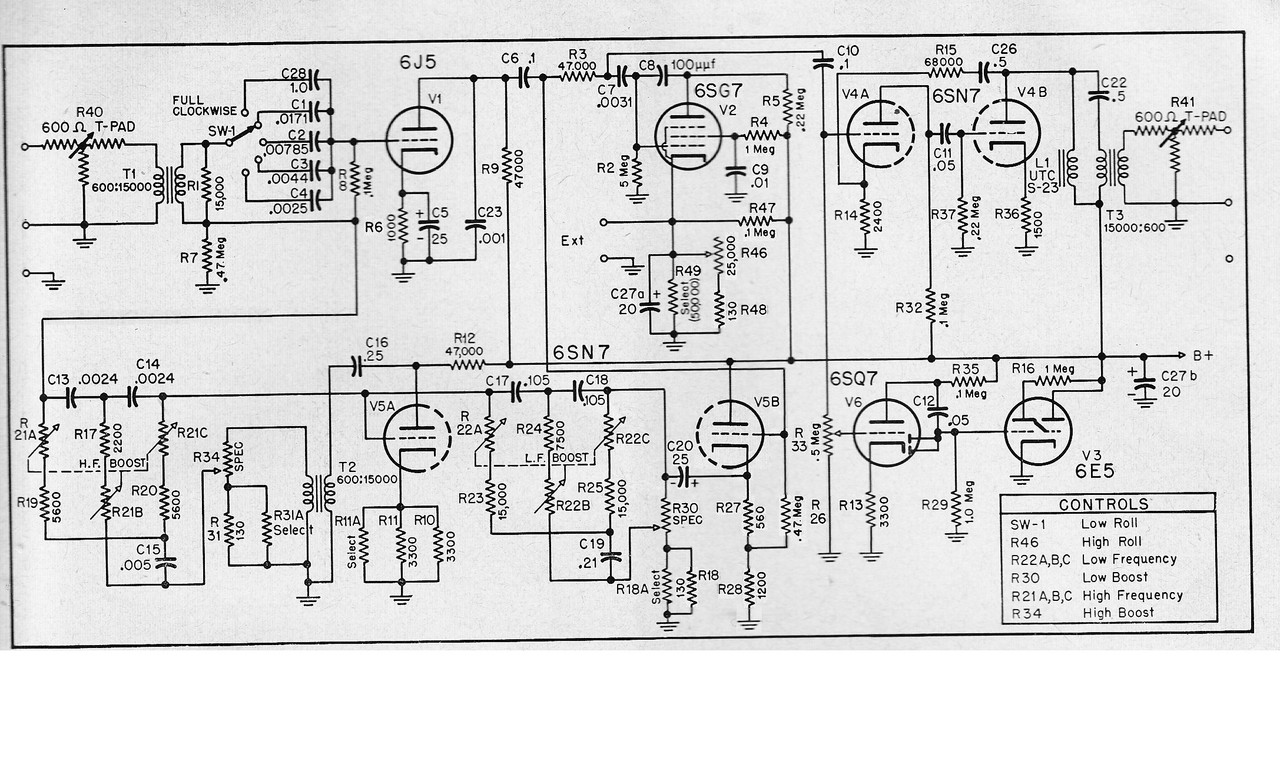

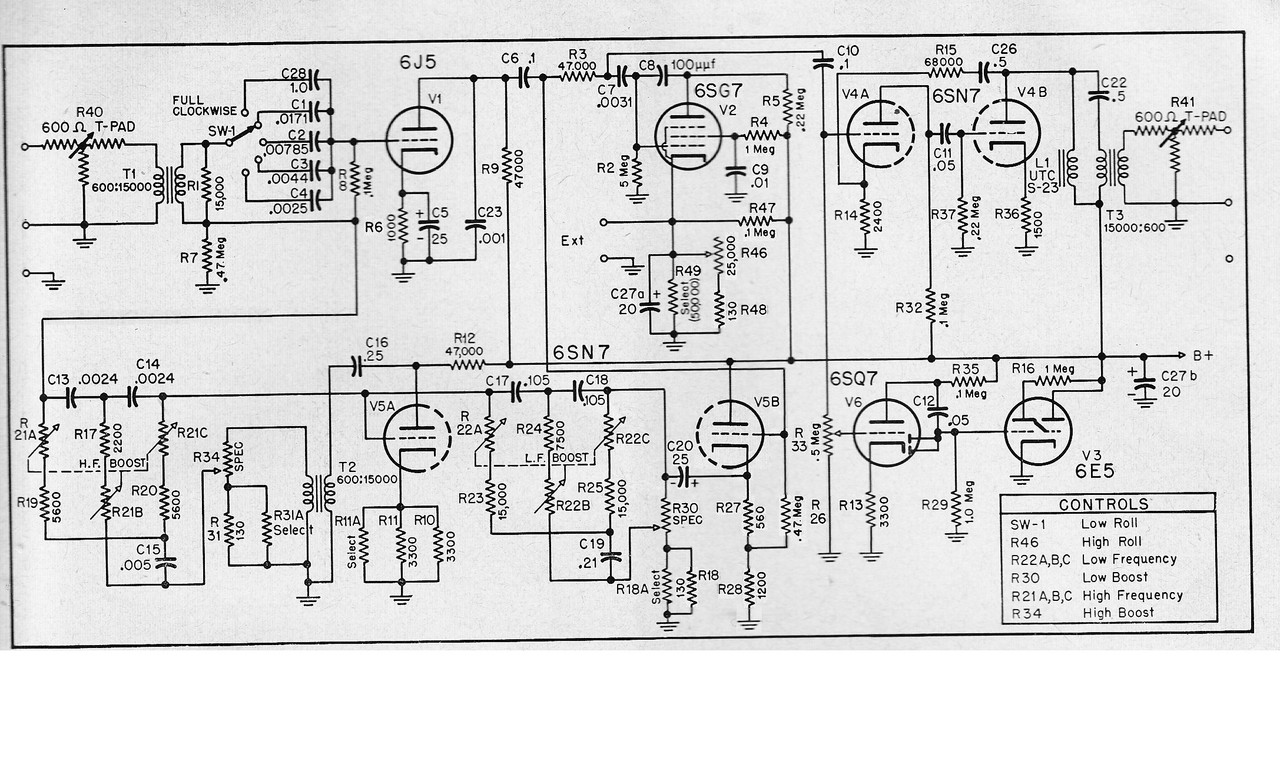

The schematic and the following pics come courtesy of the Lost in Time website so I hope they won’t mind me reproducing them here.

http://www.preservationsound.com/20...-out-the-627-equalizer-circa-195nvr/#comments

This project has considerable problems with difficult or impossible to find parts, but I hope I have found work-around solutions to these, we shall see.

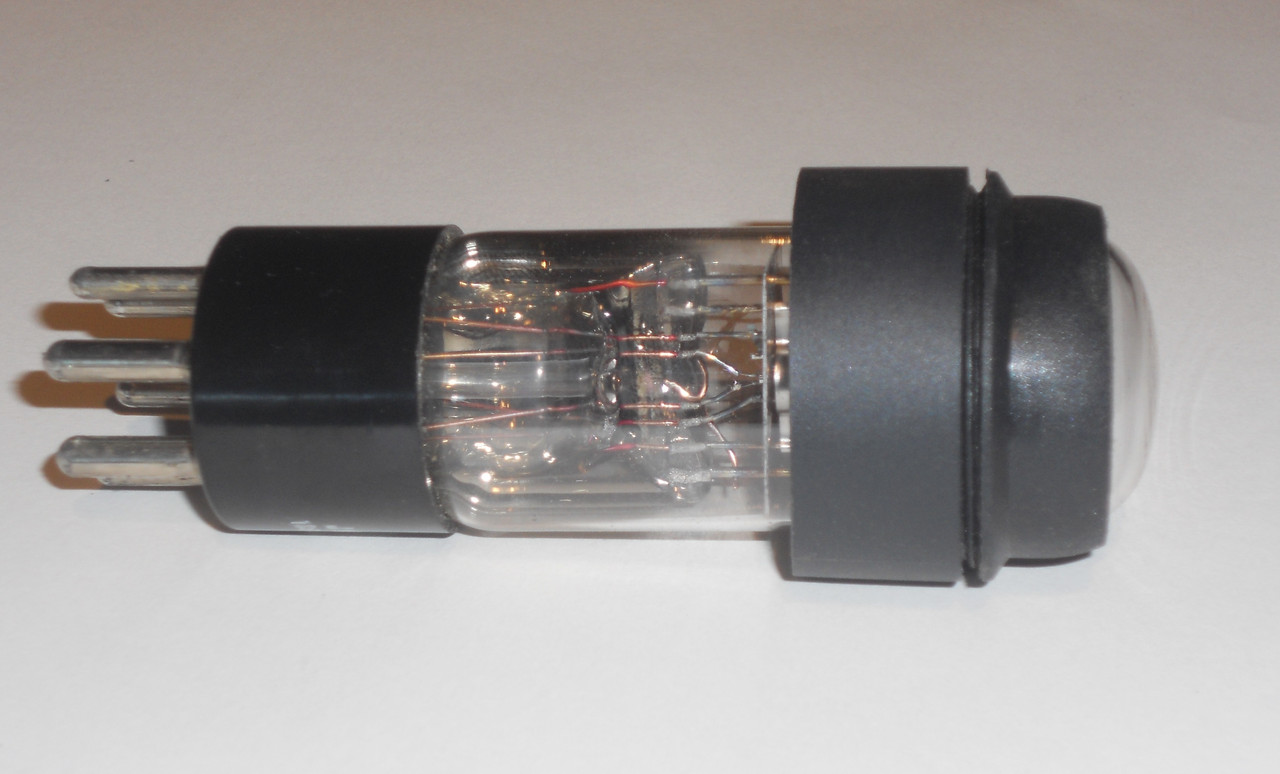

The first problem was the surround for the 6E5 magic eye tube, but I found it was possible to adapt a black GS lamp fitting to take the tube successfully.

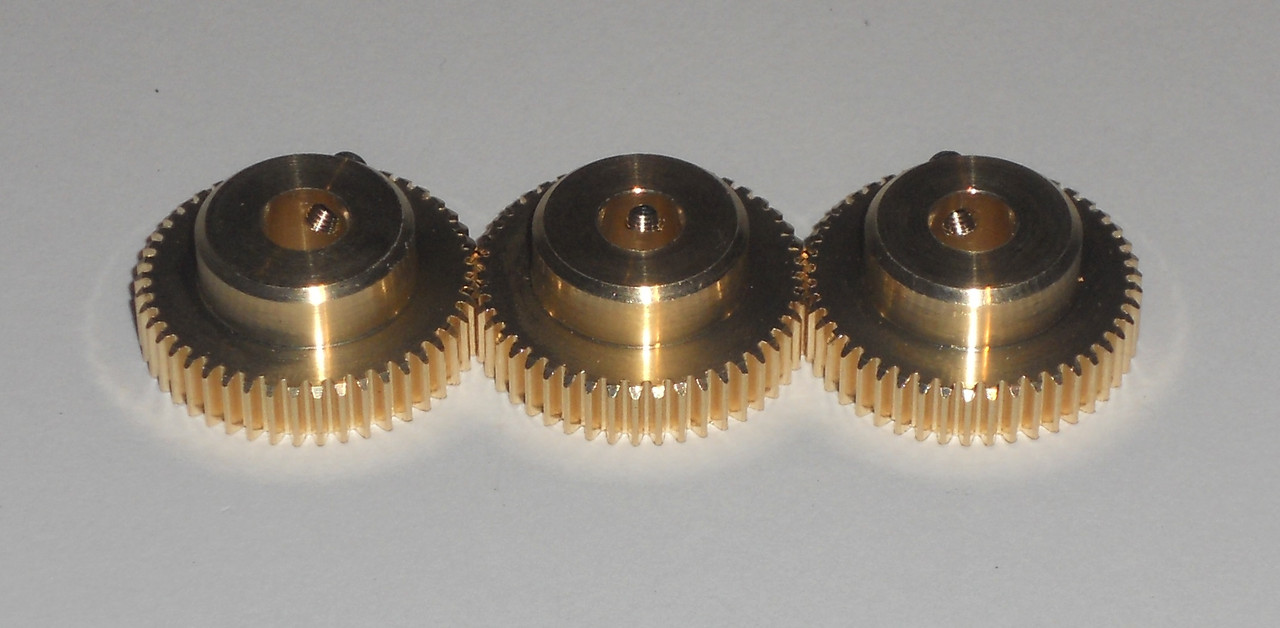

The second, more serious problem, is the triple-ganged-pots. I have found some brass cog wheels which I hope will turn the three pots simultaneously. The values of the pots can be derived from the twin tee formula using the component values in the schematic and the frequency maxima and minima on the front plate. For the LF boost the pots are ~60k/30k, covering 20-100Hz, for the HF boost they are ~11k/5.5k, ranging from 4k to 10k, so I will be obliged to use 50K/25k pots and 10k/5k pots and adjust the associated caps by the appropriate amount, for example the LF caps will go from 105/210nF to 122/250nF, not a massive change. The HF caps will go from 2.4/5nF to 2.2/4.7nF, hardly any difference, but worth doing nevertheless.

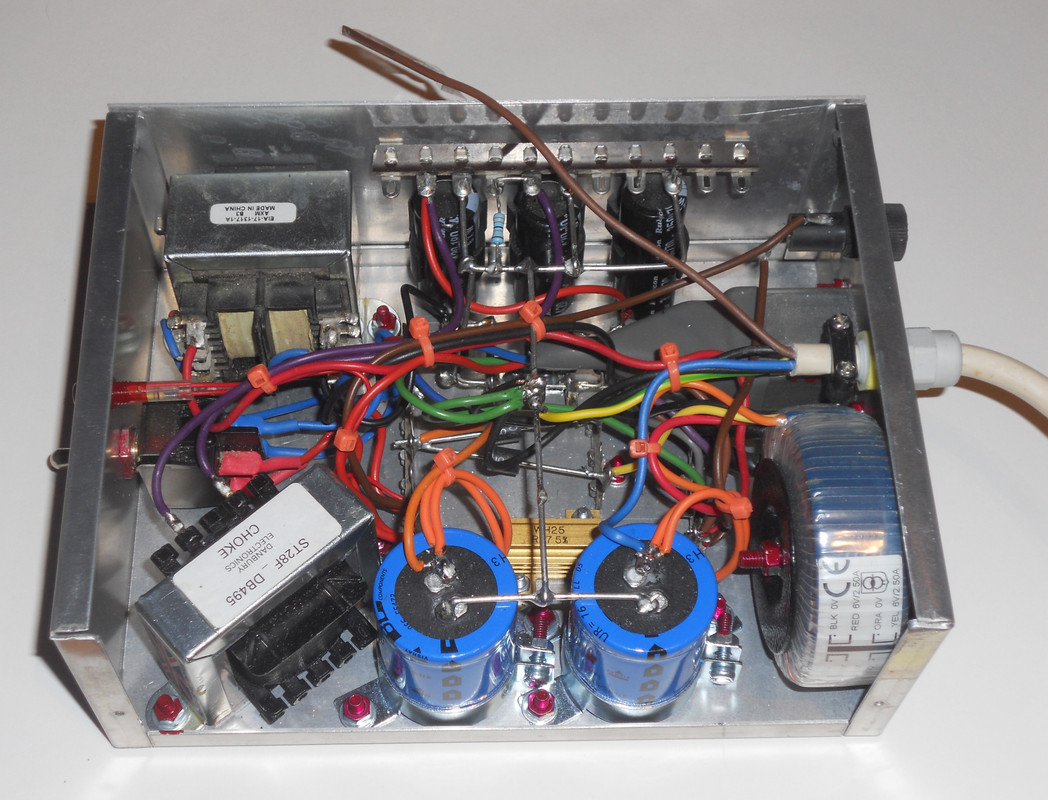

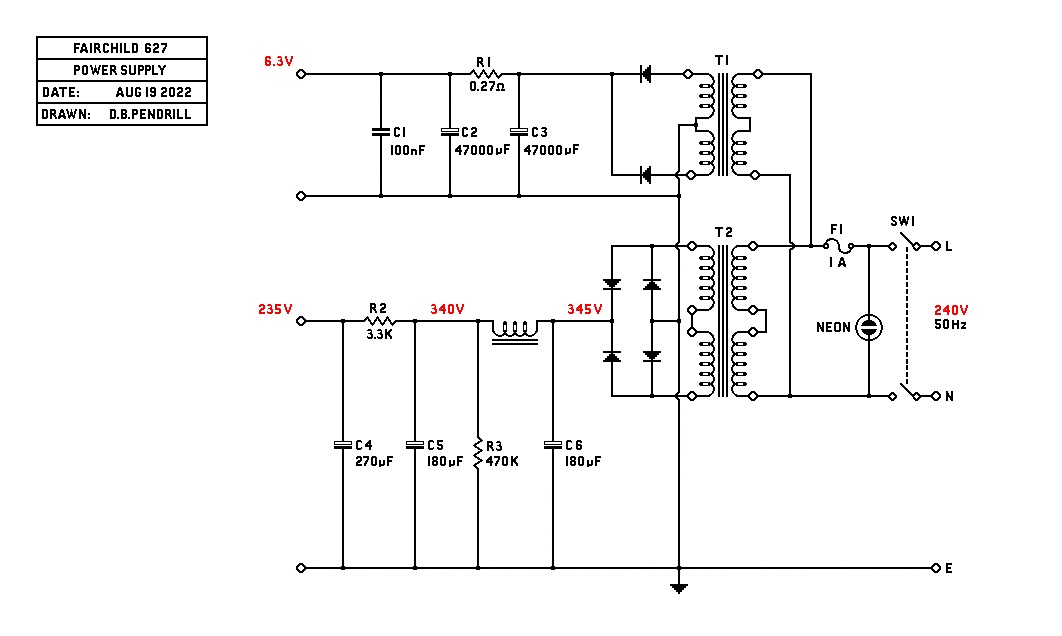

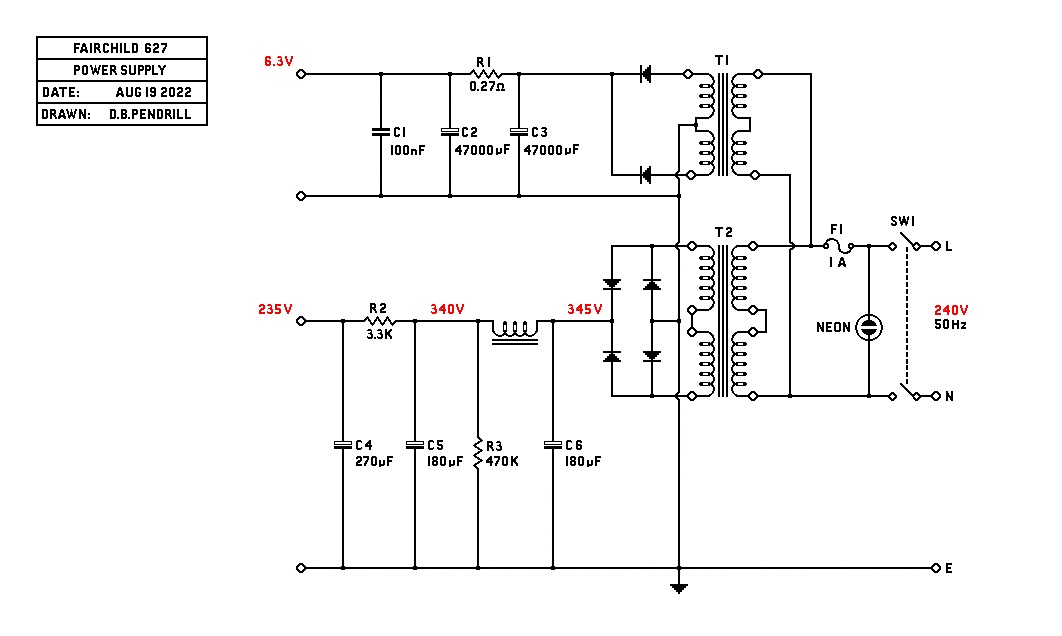

There is no power supply shown for this equaliser and I have chosen not to put one in the case even though there is room. So I have made a separate power supply to keep hum and noise well away from the chassis. This provides 2.4A DC for the tubes and about 30mA @ 230V for the HT/B+. The maximum HT for the 6E5 is 250V, so I chose ~230V to be on the safe side.

Best

DaveP

The schematic and the following pics come courtesy of the Lost in Time website so I hope they won’t mind me reproducing them here.

http://www.preservationsound.com/20...-out-the-627-equalizer-circa-195nvr/#comments

This project has considerable problems with difficult or impossible to find parts, but I hope I have found work-around solutions to these, we shall see.

The first problem was the surround for the 6E5 magic eye tube, but I found it was possible to adapt a black GS lamp fitting to take the tube successfully.

The second, more serious problem, is the triple-ganged-pots. I have found some brass cog wheels which I hope will turn the three pots simultaneously. The values of the pots can be derived from the twin tee formula using the component values in the schematic and the frequency maxima and minima on the front plate. For the LF boost the pots are ~60k/30k, covering 20-100Hz, for the HF boost they are ~11k/5.5k, ranging from 4k to 10k, so I will be obliged to use 50K/25k pots and 10k/5k pots and adjust the associated caps by the appropriate amount, for example the LF caps will go from 105/210nF to 122/250nF, not a massive change. The HF caps will go from 2.4/5nF to 2.2/4.7nF, hardly any difference, but worth doing nevertheless.

There is no power supply shown for this equaliser and I have chosen not to put one in the case even though there is room. So I have made a separate power supply to keep hum and noise well away from the chassis. This provides 2.4A DC for the tubes and about 30mA @ 230V for the HT/B+. The maximum HT for the 6E5 is 250V, so I chose ~230V to be on the safe side.

Best

DaveP

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)